Ferro-coke producing method and producing device

A manufacturing method, iron coke technology, applied to coke ovens, coke ovens with vertical carbonization chambers, direct heating and dry distillation, etc., can solve the problems of not being able to directly use molded coke, and achieve equipment simplification, energy consumption reduction, and recovery Raw material ratio reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

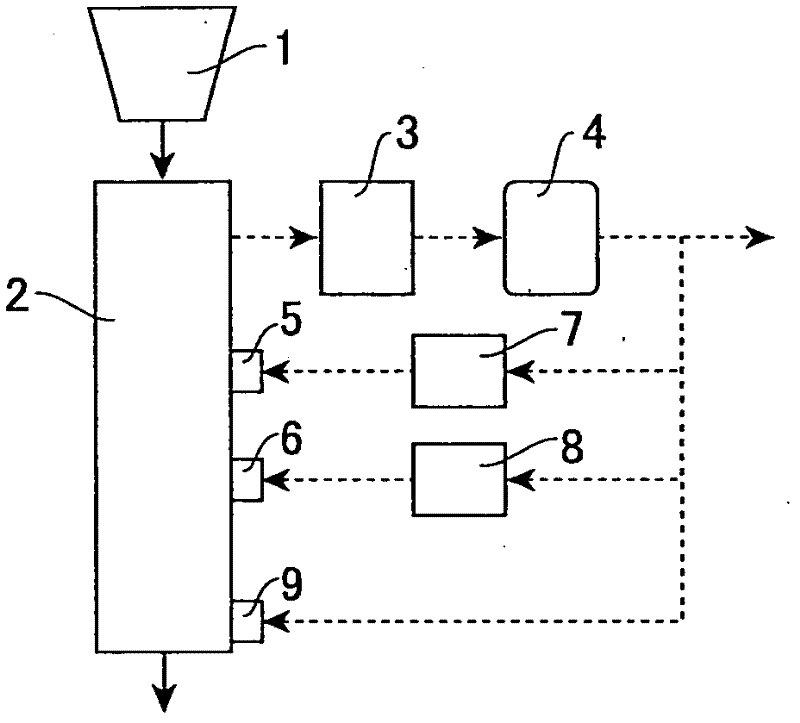

Image

Examples

Embodiment 1

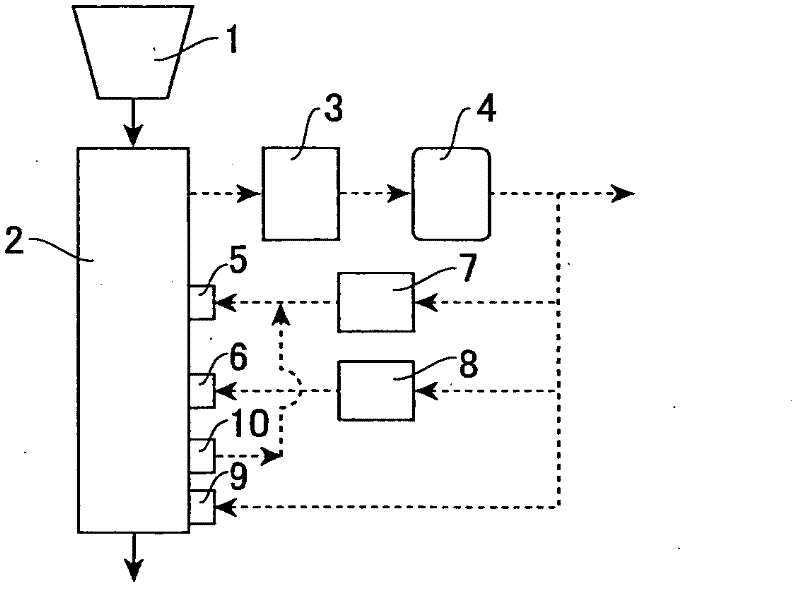

[0076] use as Figure 7 In the shown ferrocoke manufacturing test apparatus, a ferrocoke manufacturing test was carried out with and without using the cooling gas extraction tuyeres 10 . Use a cross-sectional area of 1.67m 2 vertical retort furnace. It is considered here that in the prior art of Patent Document 1, the cross-sectional area of the cooling gas introduction part is smaller than that of the high-temperature gas injection part. , the cooling gas selectively flows through the center of the furnace, and the mixing of high-temperature gas and cooling gas decreases. In the present invention, the cross-sectional area of the cooling gas injection part and the high-temperature gas injection part are the same, and the gas mixing properties of both are improved. In addition, by sieving the molded product as the raw material of iron coke, charging the molded product into the carbonization furnace while removing powder and fragments of the molded product with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com