Manufacturing method of copper-indium-gallium-selenium-sulfur five-element target material

A technology of copper indium gallium selenide sulfur and its production method, which is applied in the field of production of copper indium gallium selenide sulfur quinary targets, can solve the problems of reducing the conversion efficiency of solar cells, the inability to use DC sputtering, and complicated manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

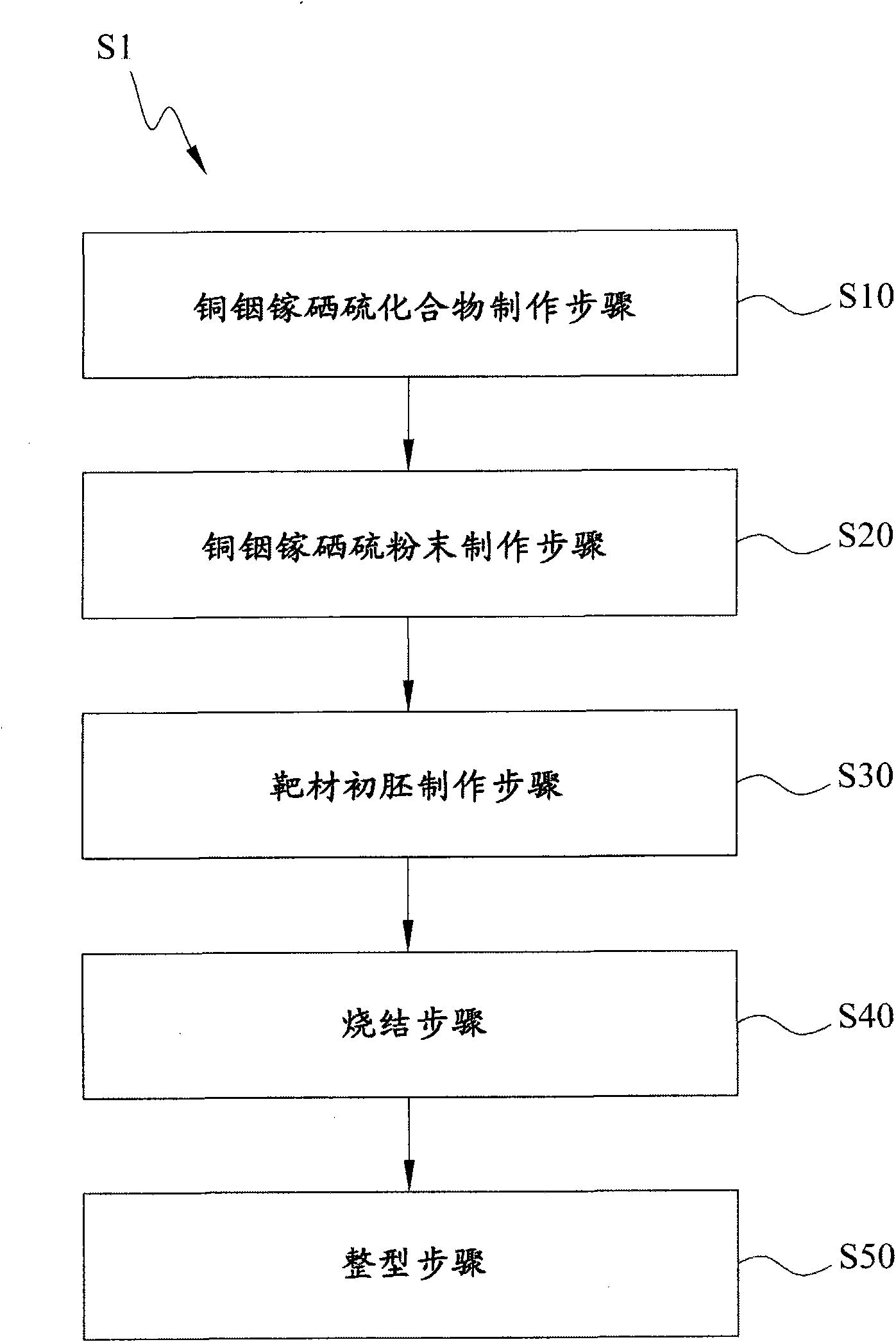

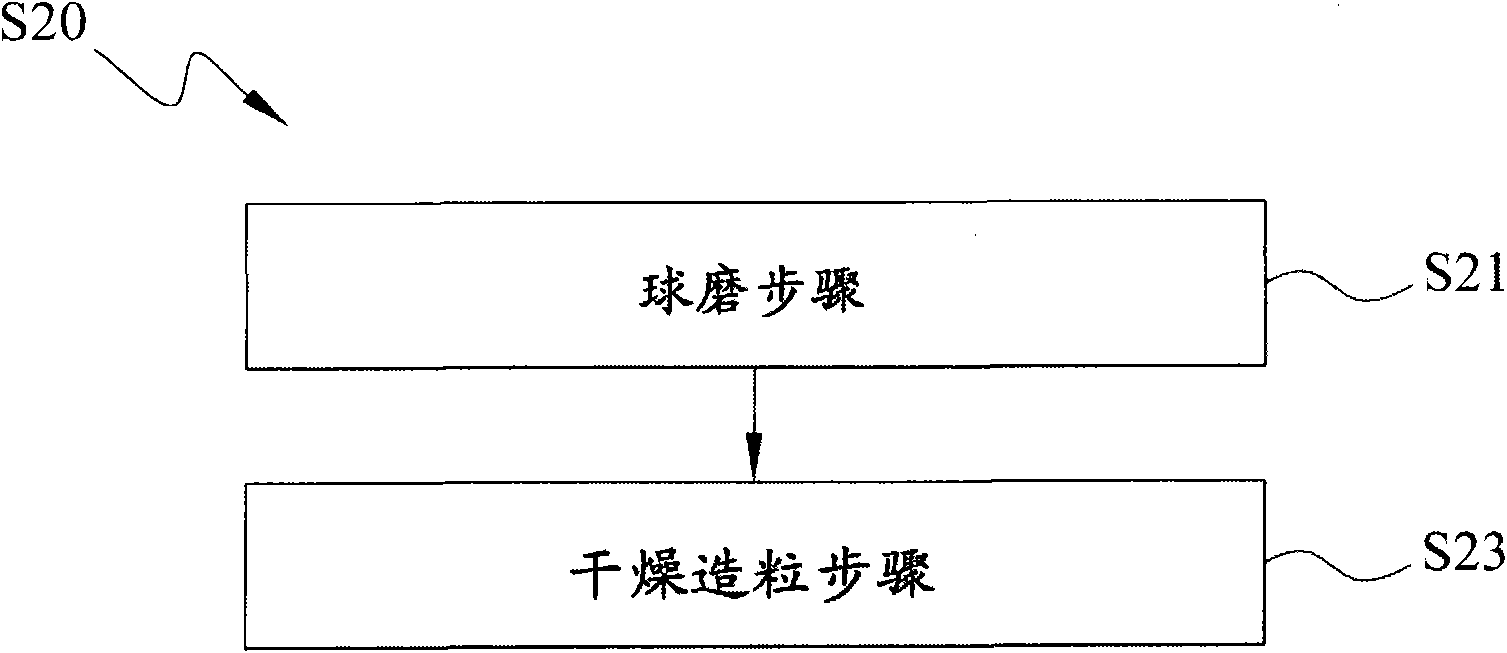

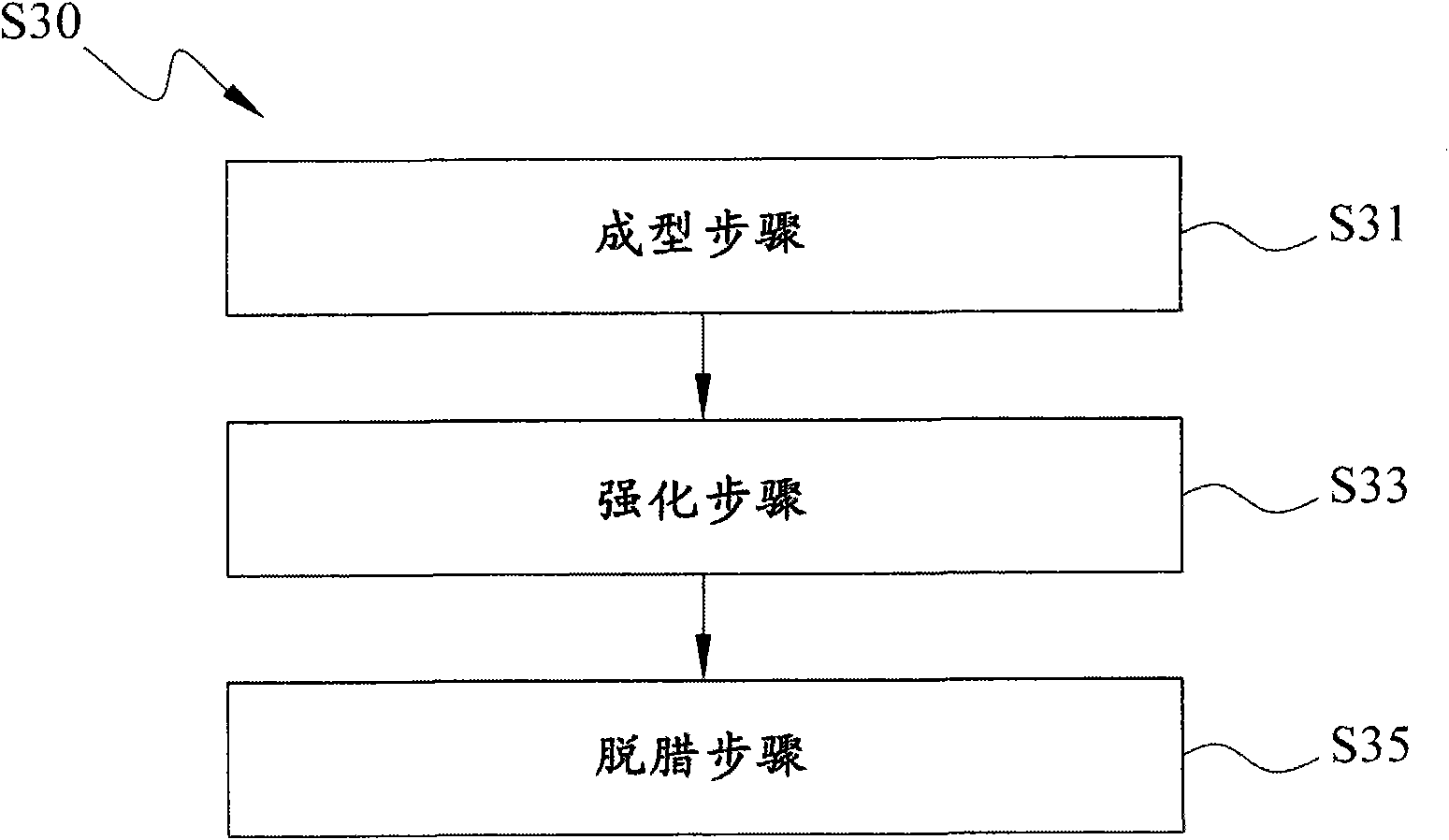

[0037] The implementation of the present invention will be described in more detail below with reference to the drawings and component symbols, so that those skilled in the art can implement it after studying this specification. figure 1 It is a flow chart of the first embodiment of the manufacturing method of the copper indium gallium selenium sulfur quinary target of the present invention. refer to figure 1 The manufacturing method S1 of the copper indium gallium selenide sulfur quinary target of the present invention comprises the manufacturing step S10 of the copper indium gallium selenide sulfur compound, the manufacturing step S20 of the copper indium gallium selenium sulfur powder, the manufacturing step S30 of the initial embryo of the target material, the sintering step S40 and the whole type step S50.

[0038] Copper indium gallium selenide sulfur compound production step S10 is mainly to mix copper, indium, gallium, selenium and sulfur element powders with a synthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com