Hollow nanocomposite oxide material and preparation thereof

A composite oxide and hollow nanotechnology, applied in the field of nanomaterials, can solve the problems affecting the synthesis of hollow silicon oxide and large limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Material Co-SiO 2 preparation of

[0019] Mix 8.00g Np-12, 15.00g cyclohexane and 3.00g n-octanol to obtain solution A; dissolve 0.02g cobalt acetate in 3.00g deionized water, and add 1.00g ammonia water to obtain solution B; 1.00g orthosilicate Methyl ester is solution C; pour solution B into solution A to obtain solution D, add solution C to solution D under stirring, and age for 8 hours; then, add 8 g of acetone, stir for 30 minutes, and centrifuge to obtain a solid;

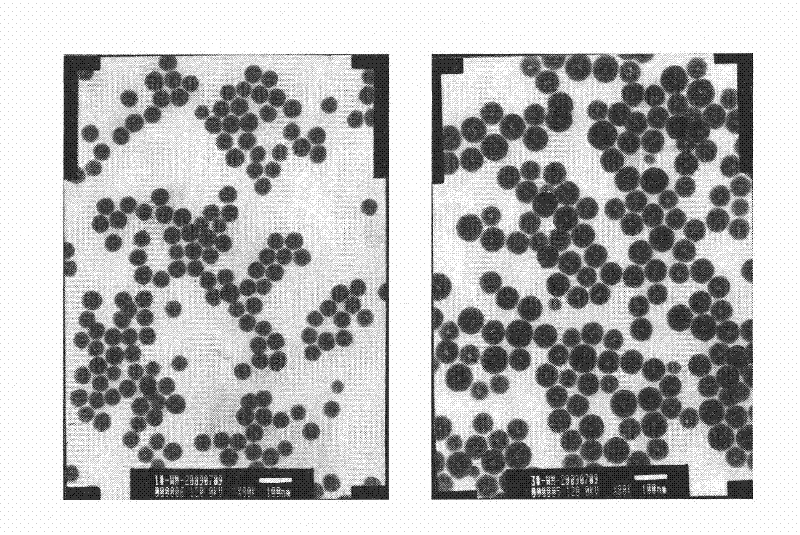

[0020] Add 25g of ethanol to the solid, heat and stir for 10min, and centrifuge; repeat this step 3-6 times until the surfactant is removed; dry at 80°C to obtain the final nanomaterial Co-SiO 2 . Such as figure 1 As shown, it can be seen that the prepared material has uniform particle size and good dispersion, the particle size is about 50nm, and the hollow diameter is about 10nm.

Embodiment 2

[0021] Example 2 Material Cu-SiO 2 preparation of

[0022] Mix 2.00g sodium dodecylbenzenesulfonate, 10.00g n-hexane and 1.00g n-butanol to obtain solution A; dissolve 0.02g cupric chloride in 2.00g deionized water, and add 2.00g ammonia water to obtain solution B; 1.00g of methyl orthosilicate is solution C; pour solution B into solution A to obtain solution D, add solution C to solution D under stirring, and age for 15 hours; then, add 8g of acetone, stir for 30 minutes, and centrifuge to obtain a solid;

[0023] Add 25g of ethanol to the solid, heat and stir for 10min, and centrifuge; repeat this step 2-5 times until the surfactant is removed; dry at 80°C to obtain the final nanomaterial Cu-SiO 2 .

Embodiment 3

[0024] Example 3 Material Zn-SiO 2 preparation of

[0025] Take 5.00g of cetyltrimethylammonium bromide, 12.00g of toluene and 2.00g of n-amyl alcohol and mix to obtain solution A; dissolve 0.02g of zinc nitrate in 4.00g of deionized water, and add 0.50g of ammonia water to obtain solution B; 1.00g of methyl orthosilicate is solution C; pour solution B into solution A to obtain solution D, add solution C to solution D under stirring, and age for 24 hours; then, add 8g of acetone, stir for 30 minutes, and centrifuge to obtain a solid;

[0026] Add 25g of ethanol to the solid, heat and stir for 10min, and centrifuge; repeat this step 4 times until the surfactant is removed; dry at 80°C to obtain the final nanomaterial Zn-SiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com