Preparation method of nanometer silicon nitride powder

A silicon nitride powder and nano technology, which is applied in the field of preparation of nano silicon nitride powder, can solve the problems of affecting product quality, uneven mixing, incomplete nitriding, etc., and achieves low cost, good sphericity, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

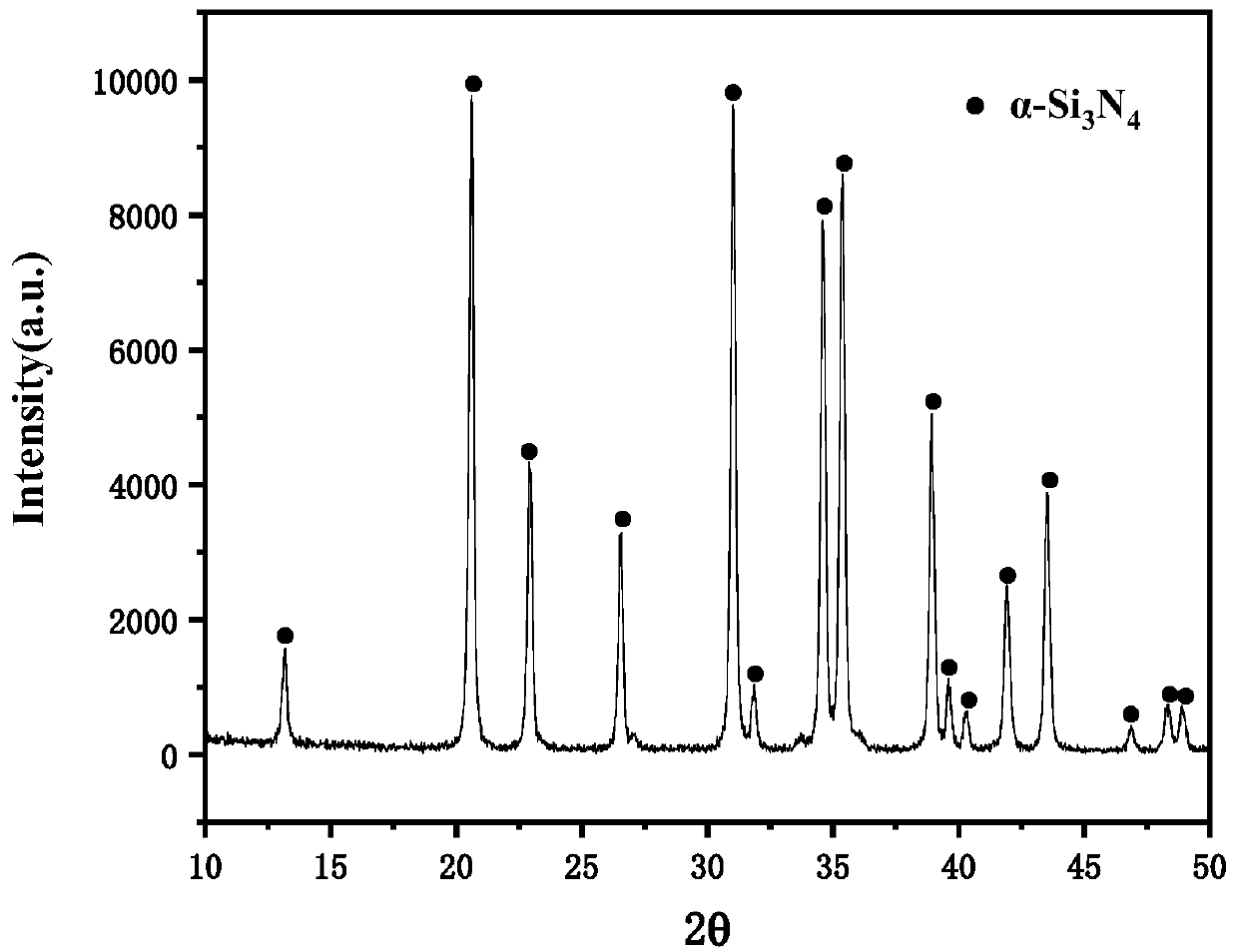

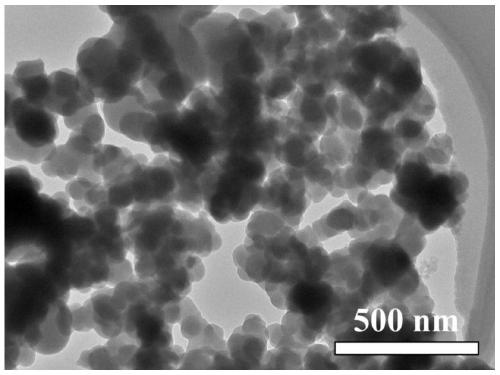

Image

Examples

Embodiment 1

[0023] 1. Weigh 1 mol of tetraethyl orthosilicate, 1 mol of glucose, and 1.5 mol of ammonium nitrate, stir the tetraethyl orthosilicate in the alcohol solution evenly, dissolve the glucose and ammonium nitrate in deionized water completely, and deionized water The volume ratio with alcohol is 2:1;

[0024] 2. Mix and stir the two solutions evenly, heat to 50°C and keep stirring until a viscous slurry is formed;

[0025] 3. Put the slurry into a furnace at 300°C to react for 1 hour, accompanied by flowing nitrogen gas, and the gas flow rate is 0.2 L / min. A mixture of silica and carbon is obtained after the reaction;

[0026] 4. React the obtained mixture of silicon dioxide and carbon at 1450° C. with nitrogen gas for 6 hours to obtain a silicon nitride product.

[0027] 5. The particle size of the silicon nitride powder prepared by this scheme is 60nm.

Embodiment 2

[0029] 1. Weigh 1 mol of tetraethyl orthosilicate, 2 mol of glucose, and 1.5 mol of ammonium nitrate, stir the tetraethyl orthosilicate in the alcohol solution evenly, dissolve the glucose and ammonium nitrate in deionized water completely, and deionized water The volume ratio with alcohol is 2:1;

[0030] 2. Mix and stir the two solutions evenly, heat to 50°C and keep stirring until a viscous slurry is formed;

[0031] 3. Put the slurry into a furnace at 300°C to react for 1 hour, accompanied by flowing nitrogen gas, and the gas flow rate is 0.2 L / min. A mixture of silica and carbon is obtained after the reaction;

[0032] 4. React the obtained mixture of silicon dioxide and carbon at 1450° C. with nitrogen gas for 4 hours to obtain a silicon nitride product.

[0033] 5. The particle size of the silicon nitride powder prepared by this scheme is 50nm.

Embodiment 3

[0035] 1. Weigh 1 mol of tetraethyl orthosilicate, 1 mol of glucose, and 1.5 mol of ammonium nitrate, stir the tetraethyl orthosilicate in the alcohol solution evenly, dissolve the glucose and ammonium nitrate in deionized water completely, and deionized water The volume ratio with alcohol is 2:1;

[0036] 2. Mix and stir the two solutions evenly, heat to 40°C and keep stirring until a viscous slurry is formed;

[0037] 3. Put the slurry into a furnace at 350°C for 1.5 hours, accompanied by flowing argon gas, and the gas flow rate is 0.1 L / min. A mixture of silica and carbon is obtained after the reaction;

[0038] 4. React the obtained mixture of silicon dioxide and carbon at 1400° C. with nitrogen gas for 6 hours to obtain a silicon nitride product.

[0039] 5. The particle size of the silicon nitride powder prepared by this scheme is 70nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com