Rutile-form titanium oxide crystals and mid-infrared filter including same

A rutile type, titanium oxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, chemical instruments and methods, etc., can solve the problem of not being able to display wavelength selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 [Synthesis of 1-Ti-Mn500 doped with manganese ions]

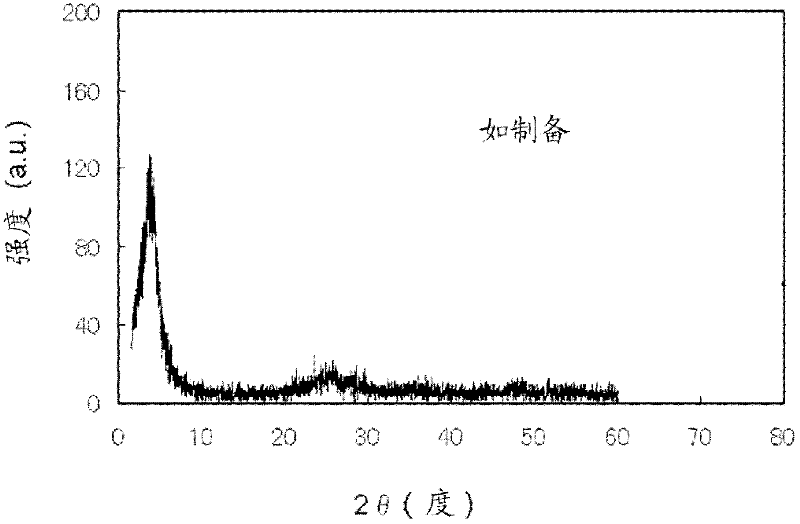

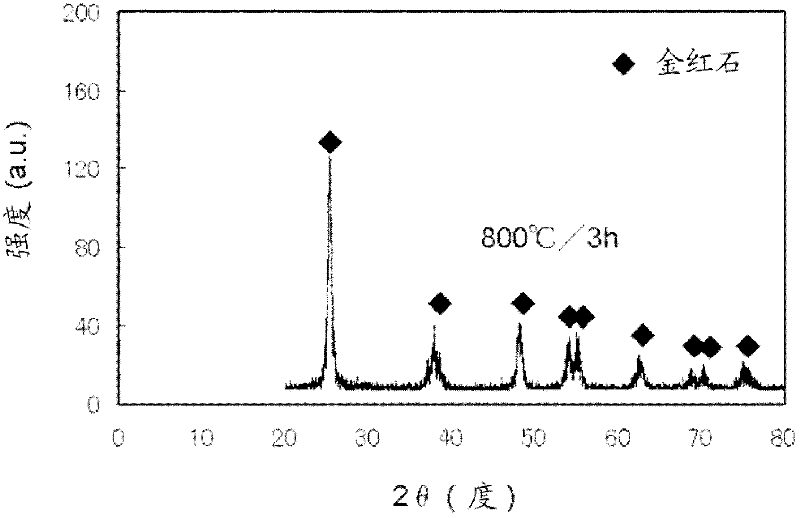

[0086] Add 0.93ml 0.1M Mn(NO 3 ) 2 , Prepare a complex solution of polyethyleneimine / manganese ions (liquid A, the molar ratio of imine / Mn is 500). On the other hand, 28% ammonia water was added dropwise to a solution of titanium lactate (manufactured by Matsumoto Pharmaceutical Co., Ltd., TC310, 20 vol%) to prepare an aqueous solution (liquid B) of pH=9. Take 100ml of liquid B, and slowly add 10ml of liquid A dropwise while stirring at room temperature (25°C). After about one hour, many precipitates were formed from the mixed solution. This precipitate was filtered, washed with water, and dried at room temperature to obtain 8.2 g of a light yellow powder (precursor). From the XRD pattern of the precursor powder, a strong X-ray diffraction peak representing a layered structure appeared on the low angle (2θ is about 3.8°) side ( figure 1 ). That is, the precursor is a complex having a layered structur...

Embodiment 2

[0089] Example 2 [Synthesis of titanium oxide 2-Ti-Mn500 doped with manganese ions]

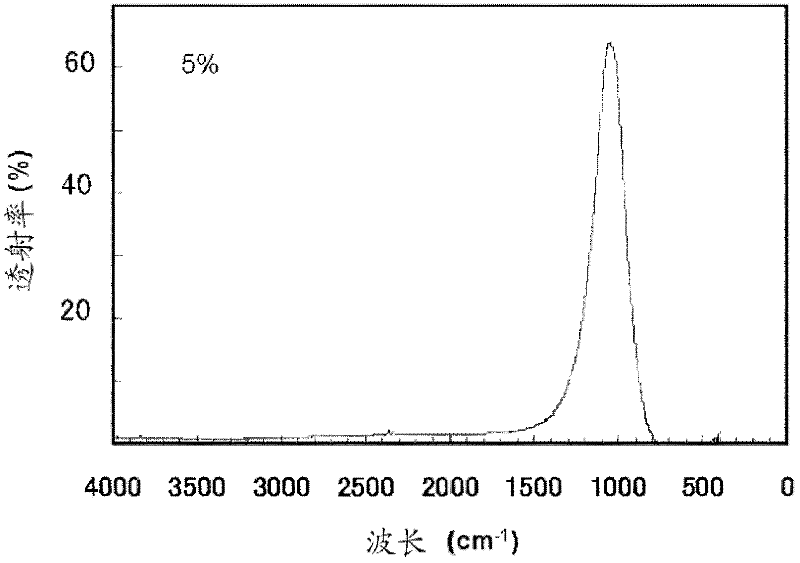

[0090] 2-Ti-Mn500 was produced in the same manner as in Example 1 except that the firing temperature was changed to 1100°C. The FT-IR spectrum of the thin slice made by mixing this sample (5%) with KBr is as follows Figure 5 shown. By increasing the firing temperature, the infrared transmission peak tends to shift slightly to the short-wavelength side. The center wavelength is 9.46 μm, the half value width is 1.89, and the transmittance is 50%.

Embodiment 3

[0091] Example 3 [Synthesis of titanium oxide doped with iron ions]

[0092] Using Fe(NO 3 ) 3 Instead of the Mn(NO 3 ) 2 (In the polymer metal complex, the molar ratio of ethyleneimine / iron = 1 / 25, 1 / 200, 1 / 500), the precursor synthesis and air calcination (800°C) were carried out under the same conditions to obtain Rutile-type titanium oxide doped with iron ions. Table 1 shows 3 kinds of titanium oxides with different iron doping amounts (iron ion content is as Fe 2 o 3 when converted value).

[0093] [Table 1]

[0094]

[0095] It was confirmed by XRD measurement that these three kinds of titanium oxides were crystals consistent with the rutile structure. In addition, the FT-IR spectrum of each sample (5% in KBr) is as follows Figure 6 shown. It shows that the larger the Fe doping amount, the more the infrared transmittance tends to increase, but at the same time the transmission peak width also becomes wider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com