Preparation method of a drug release system with water-insoluble protein powder as drug carrier

A non-water-soluble, protein powder technology, applied in peptide/protein ingredients, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as drug inability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

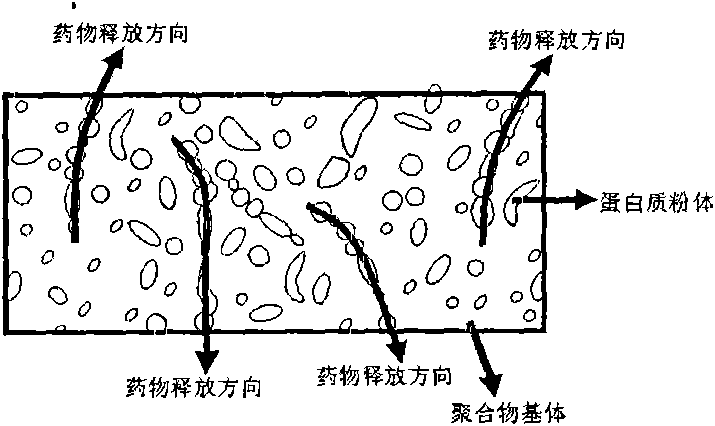

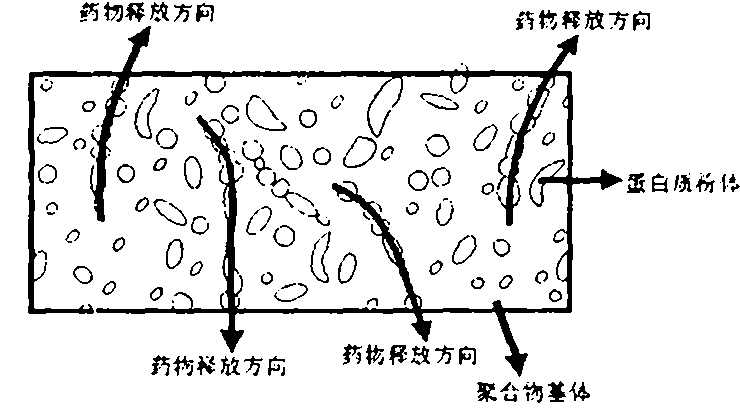

Image

Examples

specific Embodiment 1

[0036] Boil the obtained silk in a Na2CO3 solution with a mass fraction of 1% and a bath ratio of 1:20 for 3 hours, wash it with distilled water at 50°C after complete degumming, and dry it to obtain silk fiber.

[0037] Firstly, the silk fibroin fiber is beaten into a short pile of about 3mm on a rotary blade, and then ground. After grinding, water-insoluble silk fibroin powder with a particle size below 100 μm is obtained.

[0038] 1g of heparin sodium was dissolved in 19g of distilled water to obtain a drug concentration of 5% by mass. After uniform stirring, 3.3 g of water-insoluble silk fibroin powder were dispersed therein, wherein the mass ratio of water-insoluble silk fibroin powder to heparin sodium drug aqueous solution was 1:6. The mixture of the silk fibroin powder and the drug is placed and soaked for 1 hour at 25 degrees Celsius. Then dry the mixture of the silk fibroin powder and the aqueous drug solution, place it in an oven at 30° C. and heat it until all th...

specific Embodiment 2

[0040] Boil the obtained silk in a Na2CO3 solution with a mass fraction of 1% and a bath ratio of 1:20 for 3 hours, wash it with distilled water at 50°C after complete degumming, and dry it to obtain silk fiber.

[0041] Firstly, the silk fibroin fiber is beaten into a short pile of about 3mm on a rotary blade, and then ground. After grinding, water-insoluble silk fibroin powder with a particle size below 100 μm is obtained.

[0042] 2g heparin sodium is dissolved in 18g distilled water, and the medicine mass percentage that obtains medicine concentration is 10%. After uniform stirring, 3.3 g of water-insoluble silk fibroin powder were dispersed therein, wherein the mass ratio of water-insoluble silk fibroin powder to heparin sodium drug aqueous solution was 1:6. The mixture of the silk fibroin powder and the drug was placed and soaked for 2 hours at 25°C. Then dry the mixture of the silk fibroin powder and the aqueous drug solution, place it in an oven at 40 degrees centigr...

specific Embodiment 3

[0044] Firstly, the clean wool fibers are beaten into a short pile of about 3mm on a rotary blade, and then ground. After grinding, a water-insoluble wool powder with a particle size below 100 μm is obtained.

[0045] 4g heparin sodium is dissolved in 16g distilled water, and the medicine mass percentage that obtains medicine concentration is 20%. After uniform stirring, 3.3 g of water-insoluble wool powder was dispersed therein, wherein the mass ratio of water-insoluble wool powder to heparin sodium drug aqueous solution was 1:6. The mixture of wool powder and medicine was placed and soaked for 2.5 hours at 25 degrees Celsius. Then the mixture of the wool powder and the aqueous drug solution is dried, placed in an oven at 40 degrees Celsius and heated until all the distilled water is removed. The dried non-water-soluble wool powder is put into a universal high-speed pulverizer for pulverization, and the pulverization time is 6 minutes.

[0046] 15g of medical polyglycolide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com