Transparent modified copolyester and its sheet material preparation method

A copolyester and modification technology, applied in the field of modified copolyester, can solve problems such as easy sticking to the wall, high cost, and difficulty in drying slices, and achieve the effect of easy drying, solving the problem of sticking to the wall, and wide processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

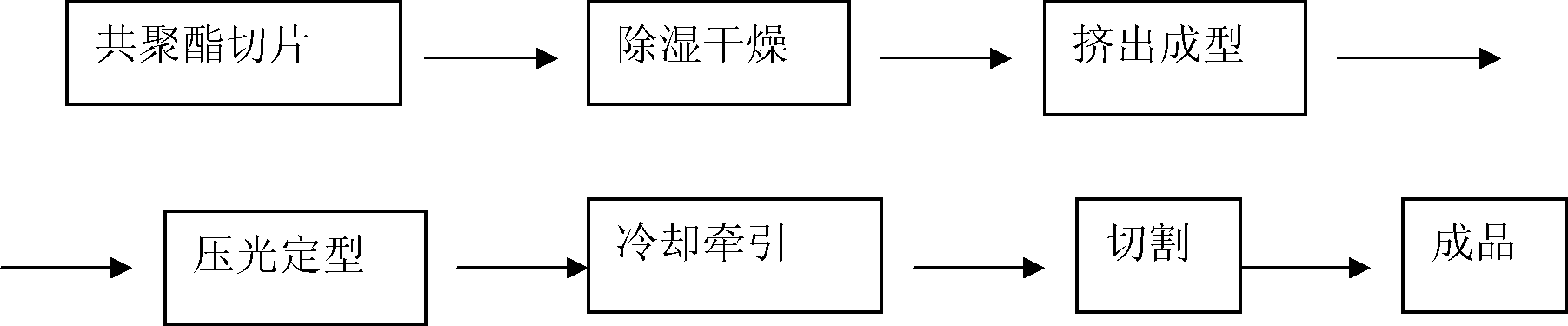

Method used

Image

Examples

Embodiment 1

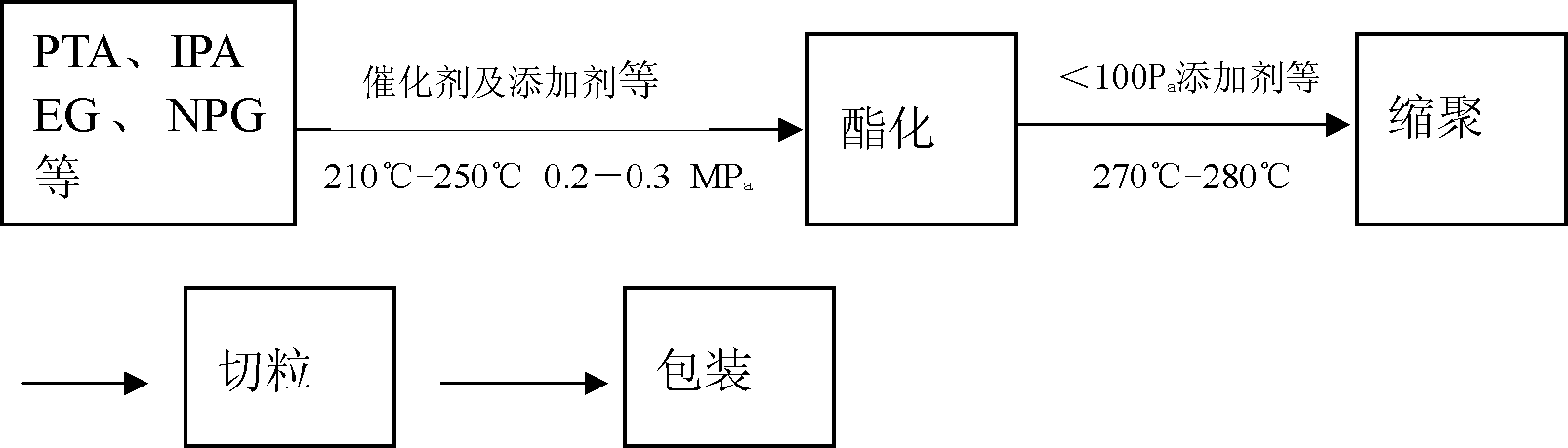

[0067] Add 150kg of purified terephthalic acid, 66.5kg of ethylene glycol, 9.4kg of neopentyl glycol, and 60g of ethylene glycol antimony into a 300L polymerization reactor, and carry out esterification at 210°C-250°C and 0.2-0.3 MPa reaction. When the water output reaches 30L, release the system pressure to normal pressure, raise the temperature in the reactor to about 280°C, and reduce the pressure below 100Pa at the same time. Under this condition, the reaction time is determined according to the change of the stirring power of the polymerization tank. Copolyester A (carboxyl-terminated content 38.8mol / t, diethylene glycol content 2.66%) with an intrinsic viscosity [η] of 0.664 was produced, and finally discharged and pelletized through nitrogen pressing.

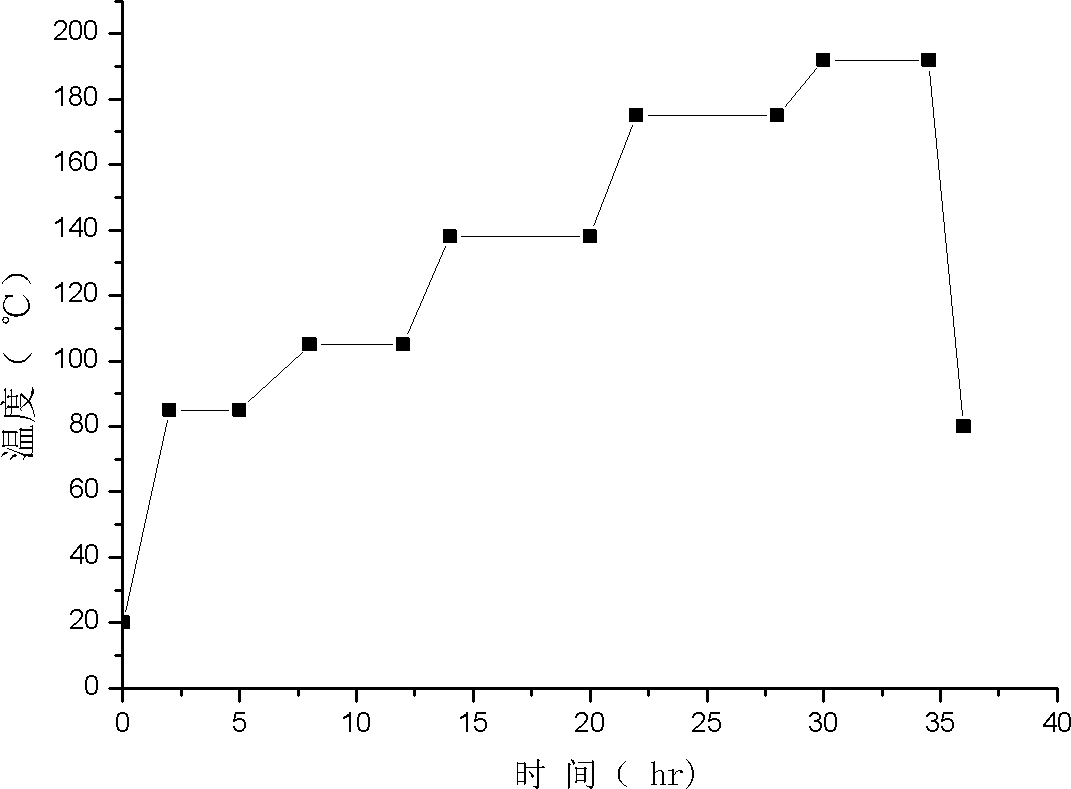

[0068] In order to further obtain the copolyester of higher intrinsic viscosity, carry out viscosification with certain heating program in vacuum drying drum to obtain intrinsic viscosity [η] be the copolyester B of 0.77...

Embodiment 2

[0074] Add 142.5kg of purified terephthalic acid, 7.5kg of purified isophthalic acid, 67kg of ethylene glycol, 14kg of neopentyl glycol, and 60g of ethylene glycol antimony into a 300L polymerization reactor. The esterification reaction is carried out at ~0.3 MPa. When the water output reaches 30L, release the system pressure to normal pressure, raise the temperature in the reactor to about 280°C, and reduce the pressure below 100Pa at the same time. Under this condition, the reaction time is determined according to the change of the stirring power of the polymerization tank. A copolyester with an intrinsic viscosity [η] of 0.687 (carboxyl-terminated content of 22.7mol / t and diethylene glycol content of 2.68%) was produced, and finally discharged and pelletized through nitrogen extrusion.

[0075] The prepared copolyester was analyzed by nuclear magnetic resonance (NMR), and the molar ratio of (PTA+IPA):MEG:NPG was 1:0.89:0.11, and the molar ratio of PTA:IPA was 1:0.05.

[00...

experiment example 1

[0078] According to the preparation method described in Example 2, the following copolyesters were prepared;

[0079] When the IPA content is zero:

[0080]

[0081] Tg represents glass transition temperature, Tcc represents cold crystallization temperature, ΔHc represents cold crystallization enthalpy, Tm represents melting temperature; ΔHm represents melting enthalpy; Tmc represents thermal crystallization temperature; ΔHmc thermal crystallization enthalpy;

[0082] The lower the ΔHc, ΔHm, and ΔHmc, the lower the crystallinity.

[0083] ΔTcc is the difference between Tcc and Tg, which is called the degree of superheating. The smaller ΔTcc is, the easier the sample is to crystallize; ΔTmc is the difference between Tm and Tmc, which is called the degree of supercooling. The smaller the ΔTmc, the easier the sample crystallizes.

[0084] It can be seen from the above table that with the increase of NPG, the values of ΔTcc and ΔTmc increase, indicating that the crystallini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com