Preparation method of isobutyl ketone synthesis catalyst

A technology of isobutyl ketone and catalyst, which is applied in the field of preparation of nickel-copper bimetallic catalysts, can solve the problems of high cost, easy loss of active components, and reduced loading of metal salts, and achieve suitable acid strength and good industrial application prospects , to avoid the effect of specific surface area decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

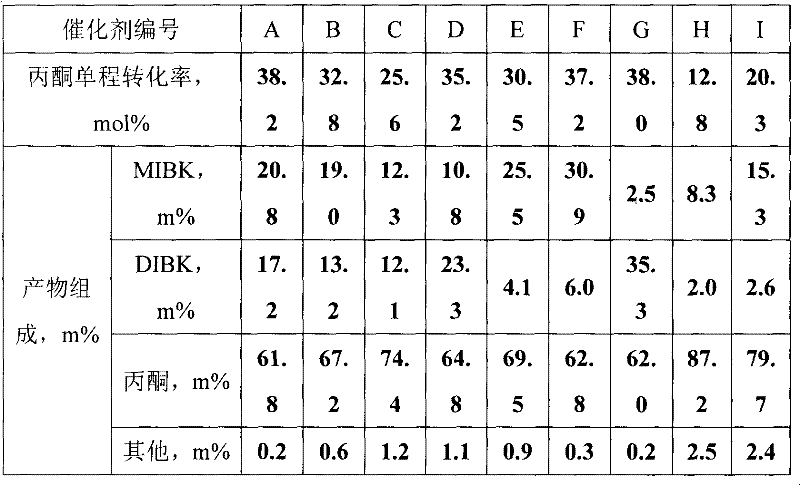

Examples

Embodiment 1

[0028] Prepare catalyst of the present invention

[0029] (1) Carrier preparation: 200g aluminum sol (solid content 30wt%), 256.4g magnesium nitrate, 10g polyethylene glycol (PEG400) and appropriate amount of deionized water were mixed and stirred until completely dissolved, then heated to 90°C and stirred and refluxed for 2 hour to form a transparent sol; the above sol was evaporated at a constant temperature at 90°C to form a xerogel, fully ground into a fine powder, and then roasted at 450°C for 4 hours to obtain a powdered magnesium oxide / alumina composite oxide; take the above composite oxide Mix 100g of material powder and 2g of methyl cellulose for 10min, add 80ml of 3wt% dilute nitric acid solution, mix well, roll the ball into a 3mm ball in a granulator, then dry at 120°C for 12 hours, and roast at 500°C for 3 hours , to prepare magnesium oxide / alumina composite carrier;

[0030] (2) Catalyst preparation by impregnation method: dissolve 79.9g nickel nitrate, 18.9g co...

Embodiment 2

[0034] Another catalyst B was prepared according to the method of Example 1, and the component content was the same as that of catalyst A, except that the composite carrier was subjected to hydrothermal treatment first, and then the active components nickel and copper were introduced by impregnation.

[0035] (1) Carrier preparation: 200g aluminum sol (solid content 30wt%), 256.4g magnesium nitrate, 10g polyethylene glycol (PEG400) and appropriate amount of deionized water were mixed and stirred until completely dissolved, stirred and refluxed at 90°C for 2 hours to form a transparent Sol; then evaporate at constant temperature to form xerogel, fully grind into fine powder, and then roast at 450°C for 3 hours to obtain powdered magnesium oxide / alumina composite oxide; after ball forming (3mm), dry at 120°C for 12 hours , calcined at 500°C for 3 hours to obtain a magnesium oxide / alumina composite carrier;

[0036] (2) Hydrothermal treatment: put the spherical carrier prepared i...

Embodiment 3~8

[0040] Catalysts C-G were prepared according to the method of Example 1, except that the catalyst composition and the type of alkaline earth metal oxide were changed. Respectively C (nickel 5.2wt%, copper 3.3wt%, magnesium oxide 12.5wt%, aluminum oxide content is the balance), D (nickel 19.5wt%, copper 13.8wt%, magnesium oxide 46.1wt%, aluminum oxide content is balance), E (nickel 15.2wt%, copper 8.9wt%, calcium oxide 29.5wt%, alumina content is the balance), F (nickel 16.5wt%, copper 5.6wt%, strontium oxide 8.2wt%, aluminum oxide content is the balance), G (nickel 13.5wt%, copper 14.6wt%, barium oxide 20.3wt%, alumina content is the balance).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com