Method for activating dopant atoms

A silicon wafer, polysilicon gate technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increased resistance, reduced device performance, and reduced proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

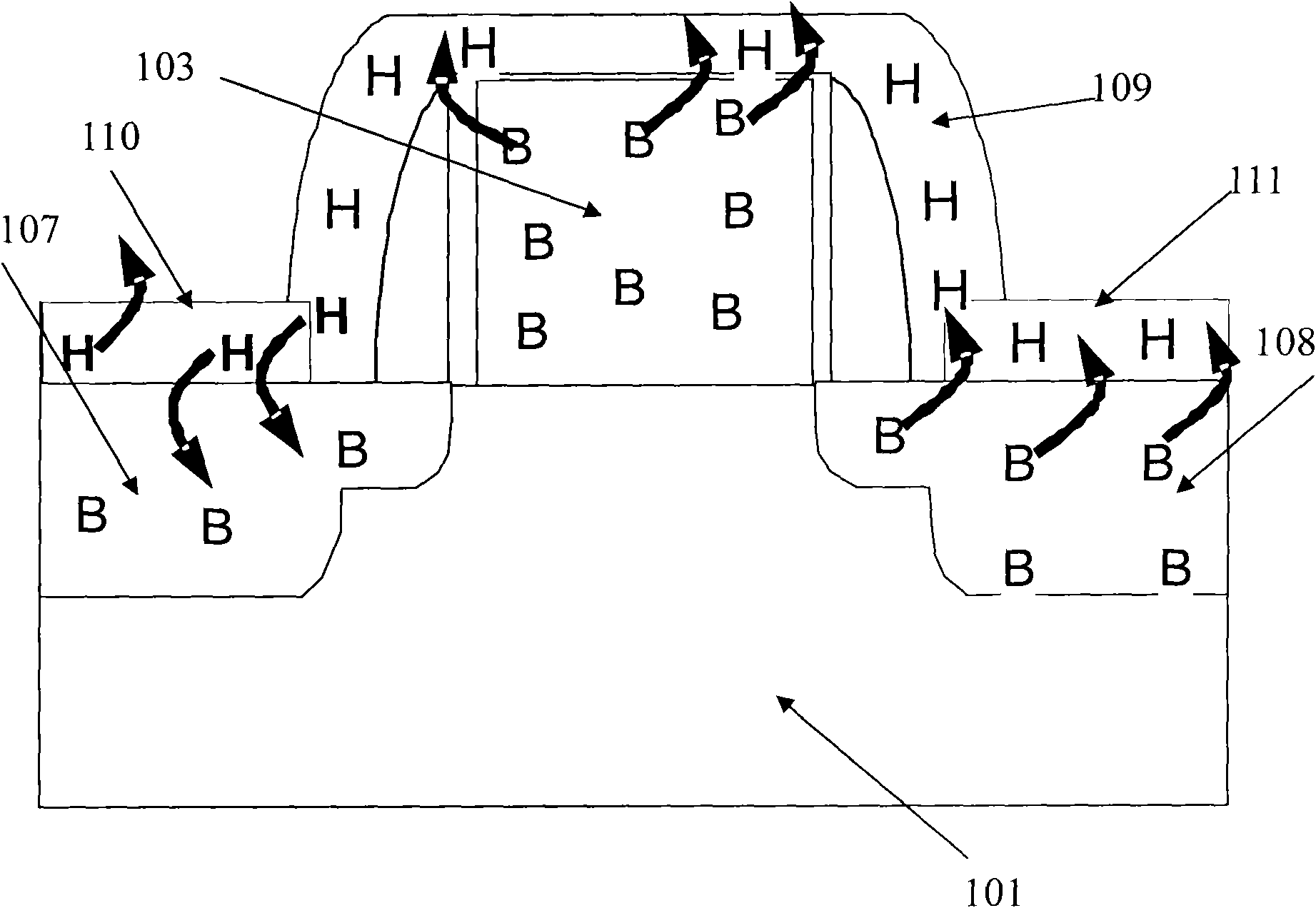

[0036] The embodiment method of the present invention adopts nitrogen gas (N 2 ) or nitrogen oxides (N 2 O) and other nitrogen-rich gas plasmas are used to process silicon wafers, with the ultimate goal of suppressing the diffusion of boron atoms. During the above-mentioned plasma treatment process, a saturated and stable silicon-nitrogen bond compound is formed on the surface of the silicon wafer as a passivation layer. This layer of passivation layer can act as a protective layer to prevent the hydrogen atoms in the SAB layer from combining with the boron atoms in the source / drain, thus preventing the deactivation of the boron atoms and increasing the proportion of activated boron atoms.

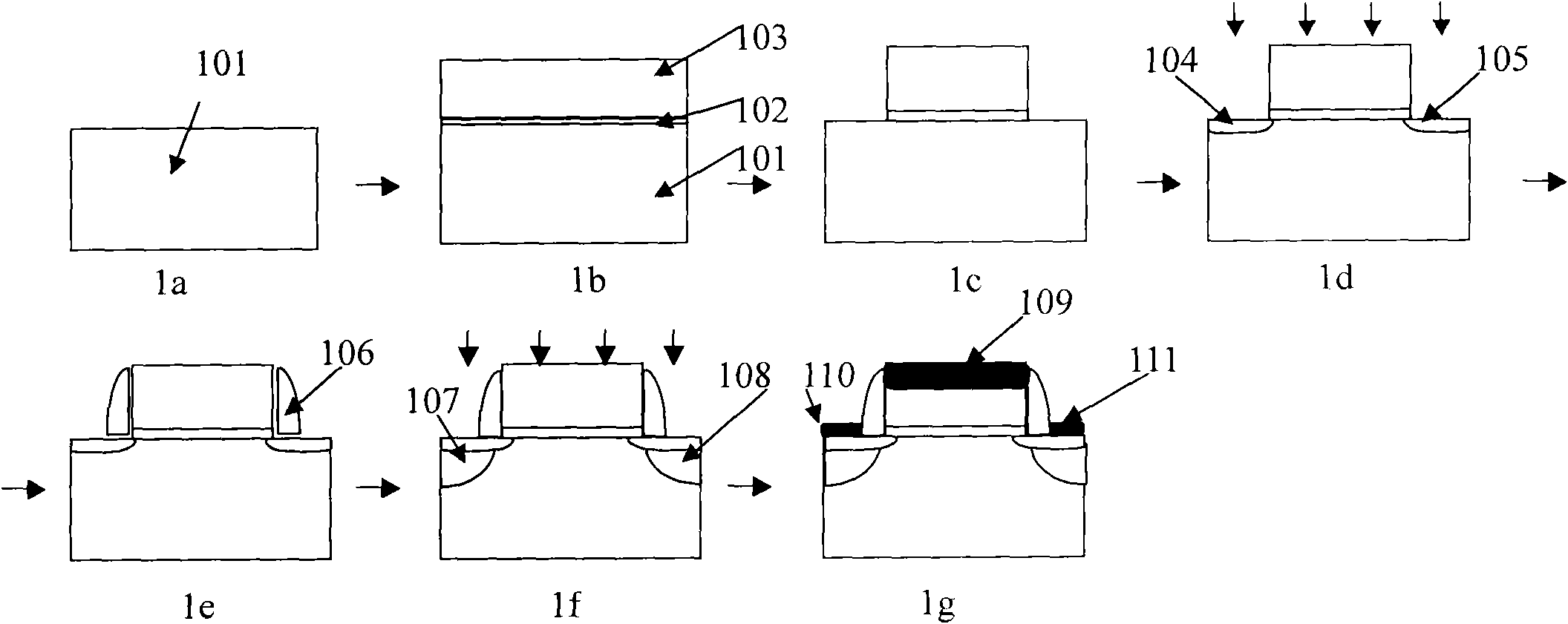

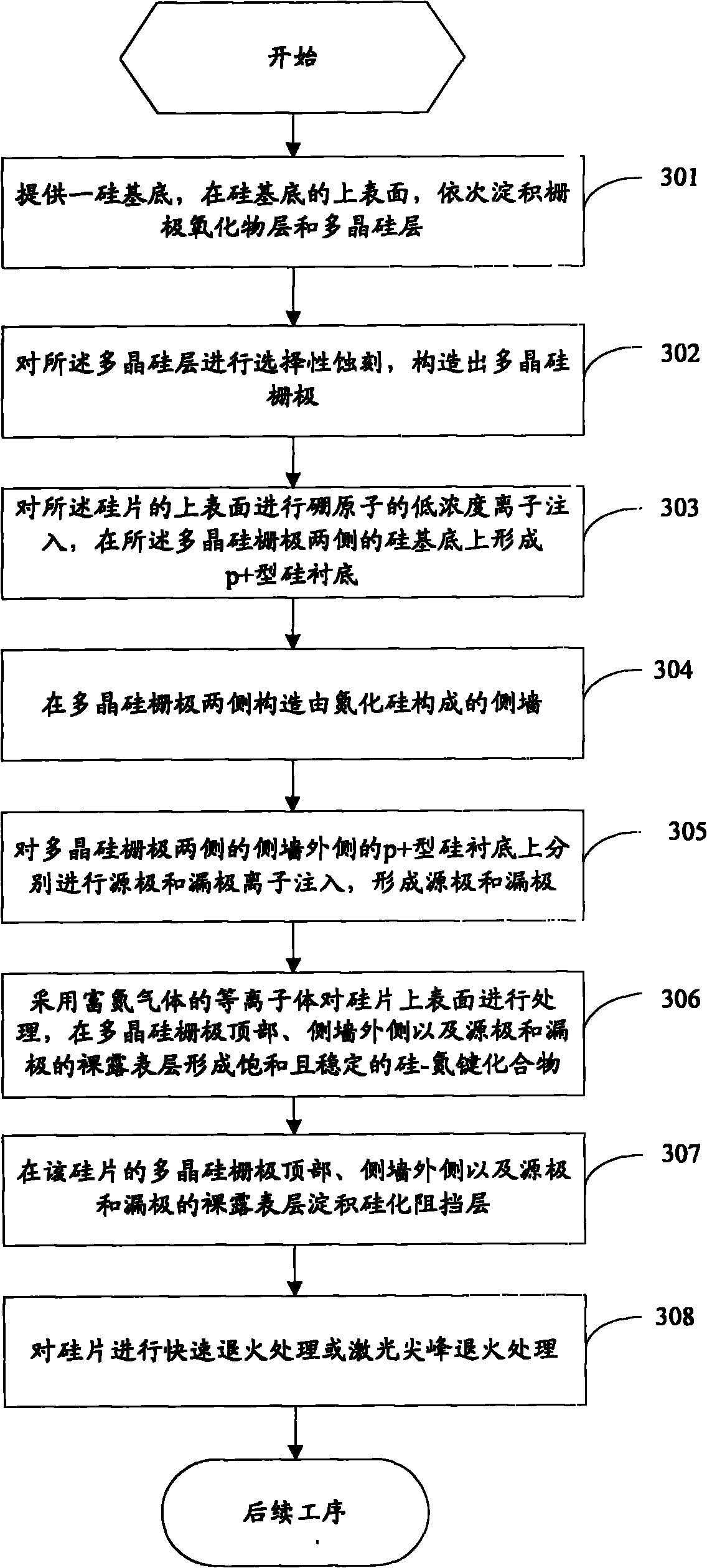

[0037] In the CMOS manufacturing process proposed by the embodiment of the present invention, the processing flow from the initial silicon substrate to the deposition of the silicide barrier layer is as follows: image 3 shown, including the following steps:

[0038] Step 301: providing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com