Zinc electrolyzing and recycling device and processing method

A technology of recycling, processing and recycling device, applied in the field of solar polysilicon ingot preparation, can solve the problems of non-reusable by-product slag phase, waste of environment, large amount of slag, etc., achieve considerable market prospects, short investment cycle, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

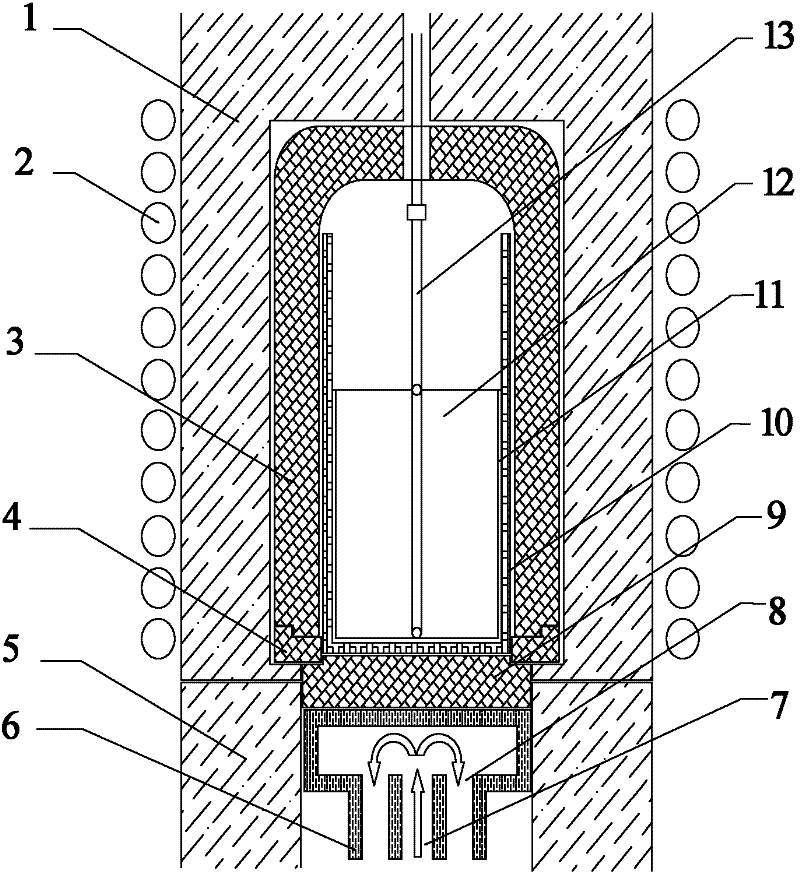

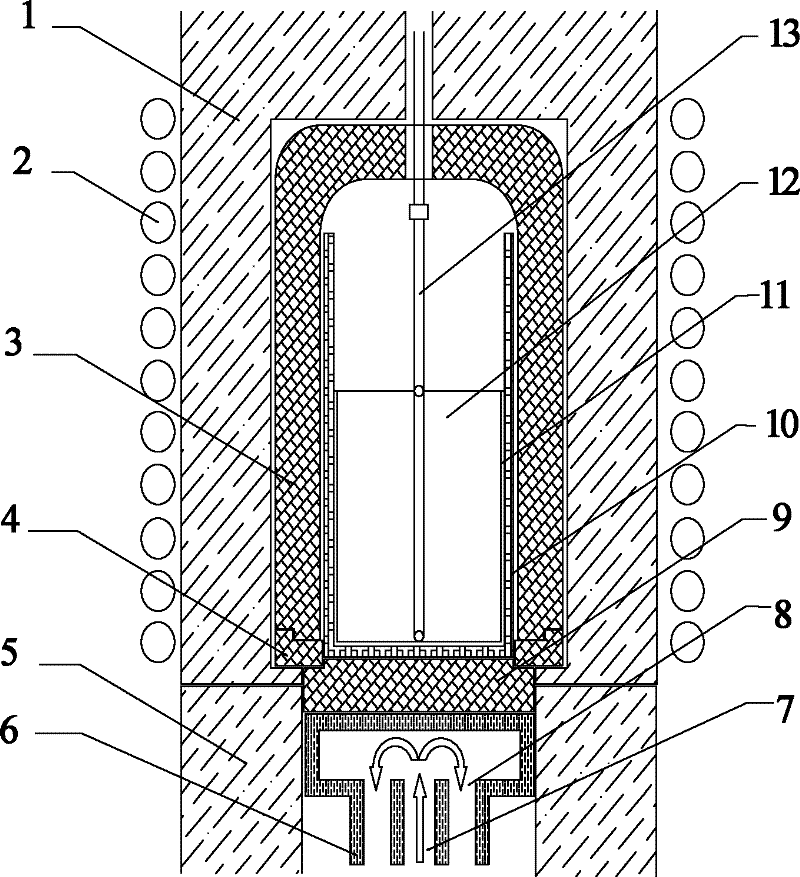

[0042] Put 200Kg of industrial silicon and 5Kg of zinc into the quartz crucible, turn on the heating power supply, energize the induction heating coil, the power is 200kW, the graphite heating sleeve will generate heat by induction, and heat the silicon and zinc in the quartz crucible , silicon and zinc begin to melt slowly as the temperature rises. When the silicon in the quartz crucible is completely melted to form a silicon-zinc alloy melt, a thermocouple temperature measuring device is used to measure the temperature of each point in the vertical direction inside the quartz crucible, and the induction heating power controller is adjusted. Start the directional solidification lifting device, and drive the quartz crucible containing the alloy melt and the graphite chassis to pull down together to produce directional solidification, and the falling speed is 10mm / h. When the alloy melt in the quartz crucible is completely solidified, cut off the current of the induction heatin...

Embodiment 2

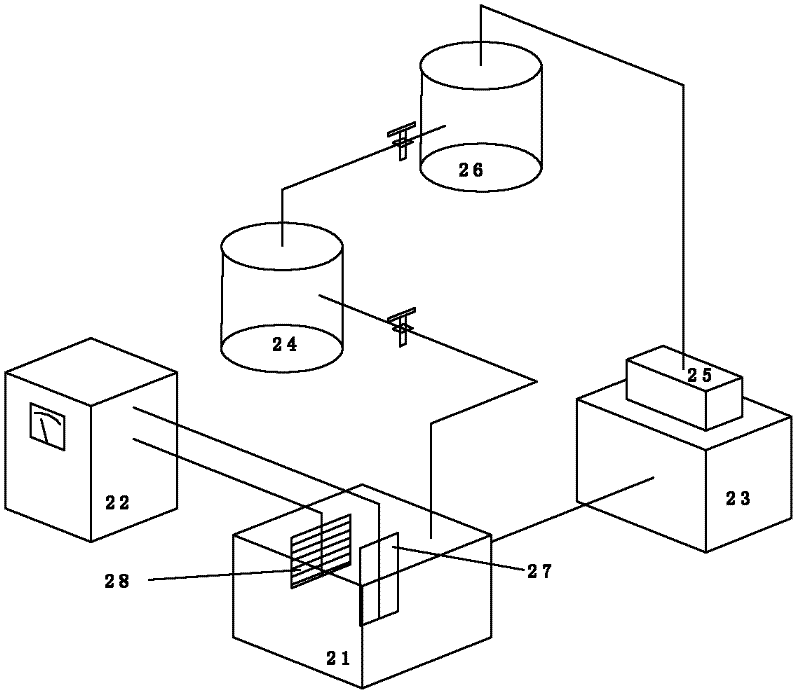

[0044] Technological process is with embodiment 1. Put 240kg of industrial silicon and 10kg of zinc into a quartz crucible, turn on the heating power supply, and energize the induction heating coil with a power of 180kW. After all the silicon and zinc in the crucible are melted, adjust the induction heating power controller to start the directional solidification lifting device, the descending speed is 15mm / h. After the orientation process is completed, the alloy silicon ingot is taken out, and the upper 25% is cut off. The remaining part is determined to be a polycrystalline silicon ingot with a purity of 99.999611%, and the crystal grains of the silicon ingot are larger than 1.1 mm and are vertically oriented columnar crystals, and the resistivity is 0.49-1Ω·cm. figure 2 In the electrolyzer shown, the zinc is recovered by the electrolytic process, while the remaining silicon is recovered by pickling. The recovered silicon was placed in a crucible, mixed with 300 g of germ...

Embodiment 3

[0046] Technological process is with embodiment 1. Put 220kg of industrial silicon and 5kg of zinc into a quartz crucible, turn on the heating power supply, and electrify the induction heating coil with a power of 160kW. After all the silicon and zinc in the crucible are melted, adjust the induction heating power controller. Start the directional solidification lifting device, and the descending speed is 5mm / h. After the orientation process is completed, the alloy silicon ingot is taken out, and the upper 15% is cut off. The remaining part is determined to be a polycrystalline silicon ingot with a purity of 99.999396%, and the crystal grains of the silicon ingot are larger than 5mm and are vertically oriented columnar crystals, and the resistivity is 4.4·cm~5Ω·cm. figure 2 In the electrolyzer shown, the zinc is recovered by the electrolytic process, while the remaining silicon is recovered by pickling. The recovered silicon is placed in a crucible, mixed with 250 g of germa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com