Composite heat stabilizer and preparation method

A compound heat stabilizer and heat stabilizer technology, which is applied in the field of compound heat stabilizer and preparation, to prepare compound heat stabilizer for PVC materials, can solve problems such as unsatisfactory effect, not in line with the national conditions of production, and performance needs to be improved. Achieve the effect of anti-ultraviolet ability, excellent color protection ability, and reduce emulsification process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

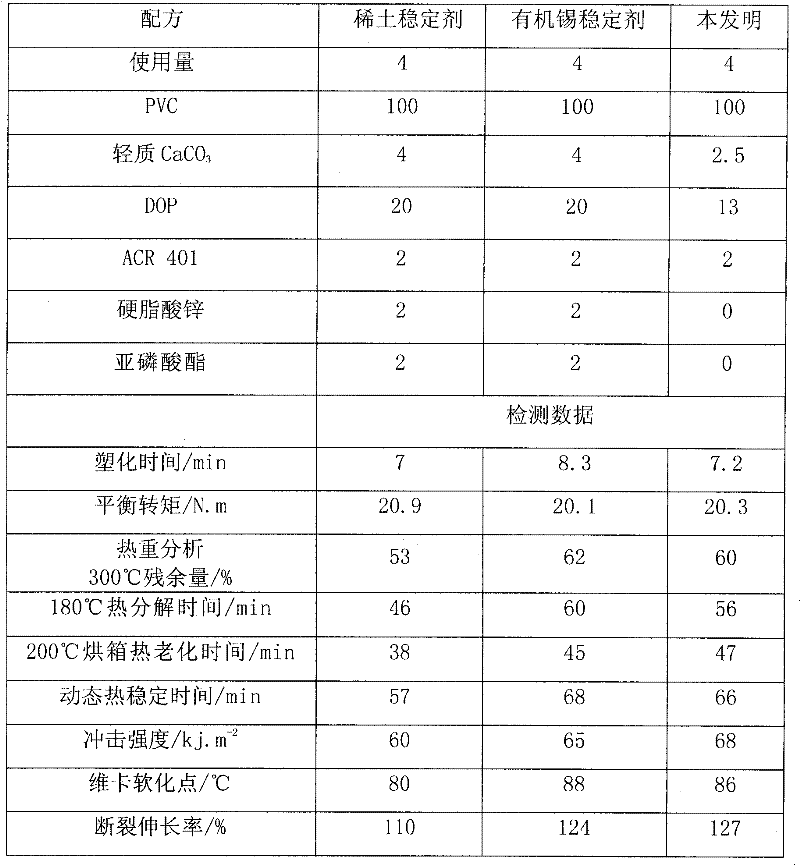

Image

Examples

Embodiment 1

[0025] 1. Add 8kg of stearic acid and 20kg of deionized water into the reactor with grinder, heat and stir, when the temperature reaches 65-85℃, stir for 15-30min, add 5L rare earth nitrate with a molar concentration of 2mol / L After stirring uniformly, add 50L of ammonia solution with a molar concentration of 0.6mol / L within 50min, continue to stir, keep at constant temperature for 45min, filter while hot, dehydrate and dry to make rare earth stearate.

[0026] 2. Dissolve 10kg of stearic acid in 20kg of water, heat to 75°C, add 1kg of zinc sulfate, add 15L of 2mol / L calcium hydroxide, stir at constant temperature for 25min, then dehydrate, dry, and grind to make zinc stearate.

[0027] 3. Take 10kg of rare earth stearate, 3kg of zinc stearate, and 1.5kg of PE wax into a centrifugal device for dehydration, then transfer to the reaction vessel, equipped with a reflux device, add 8kg of mineral oil, 0.5kg of β-diketone, and heat to 85 ℃, keep constant temperature for 30min, add 0.2kg...

Embodiment 2

[0029] 1. Add 4kg of cyanuric acid and 10kg of deionized water into a reactor equipped with a grinder, heat and stir, when the temperature reaches 65-85℃, stir for 15-30min, add 4.5L rare earth nitrate with a molar concentration of 2mol / L After stirring uniformly, add 30L of ammonia aqueous solution with a molar concentration of 0.8mol / L within 30min, continue to stir, keep at a constant temperature for 45min, filter while hot, dehydrate and dry to make rare earth hydrouric acid.

[0030] 2. Dissolve 8kg stearic acid in 16kg water, heat up to 75℃, add 0.8kg zinc sulfate, slowly add 13L 2mol / L calcium hydroxide, stir at constant temperature for 25min, then dehydrate, dry, and grind to make stearin Zinc acid.

[0031] 3. Take 9kg of rare earth hydrouric acid, 3kg of zinc stearate, and 1.3kg of PE wax into the centrifuge device for dehydration, then transfer to the reaction vessel, equipped with a reflux device, add 8kg of mineral oil, 0.4kg of β-diketone, and heat to 85 ℃, keep cons...

Embodiment 3

[0033] 1. Add 10kg of stearic acid and 24kg of deionized water into a reactor with a grinder, heat and stir, when the temperature reaches 65-85℃, stir for 15-30min, add 6.5L rare earth nitrate with a molar concentration of 2mol / L After stirring uniformly, add 30L of ammonia aqueous solution with a molar concentration of 1.2mol / L within 30min, keep stirring, after 45min at a constant temperature, filter while hot, dehydrate and dry to prepare rare earth stearate.

[0034] 2. Dissolve 12kg of stearic acid in 24kg of water, heat up to 75℃, add 1.1kg of zinc sulfate, slowly add 17L of 2mol / L calcium hydroxide, stir at constant temperature for 25min, then dehydrate, dry, and grind to make stearin Zinc acid.

[0035] 3. Take 1.2 kg of rare earth stearate, 3.3 kg of zinc stearate, and 1.7 kg of PE wax into a centrifugal device for dehydration, and then move it into the reaction vessel. After equipped with a reflux device, add 8 kg of mineral oil and 0.6 kg of β-diketone. Raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com