Method for preparing silicon carbide alloy negative electrode material for lithium ion battery

A technology for lithium ion batteries and alloy negative electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low theoretical lithium storage capacity, poor dispersion of nano-silicon particles, capacity attenuation, etc., and achieves simple and controllable process. The effect of low preparation cost and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

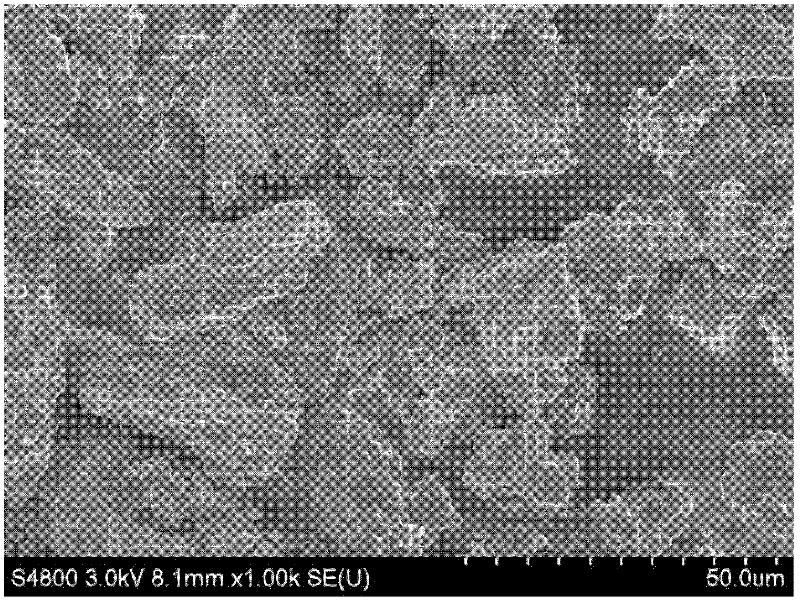

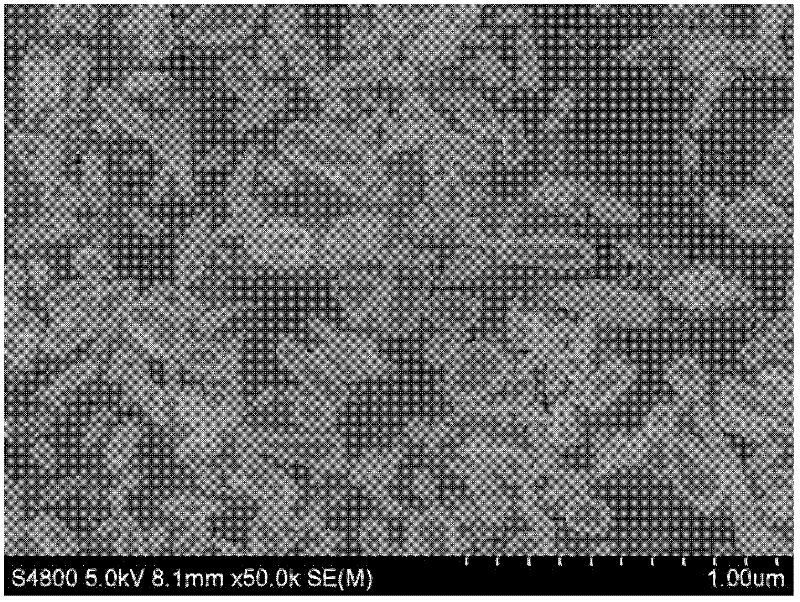

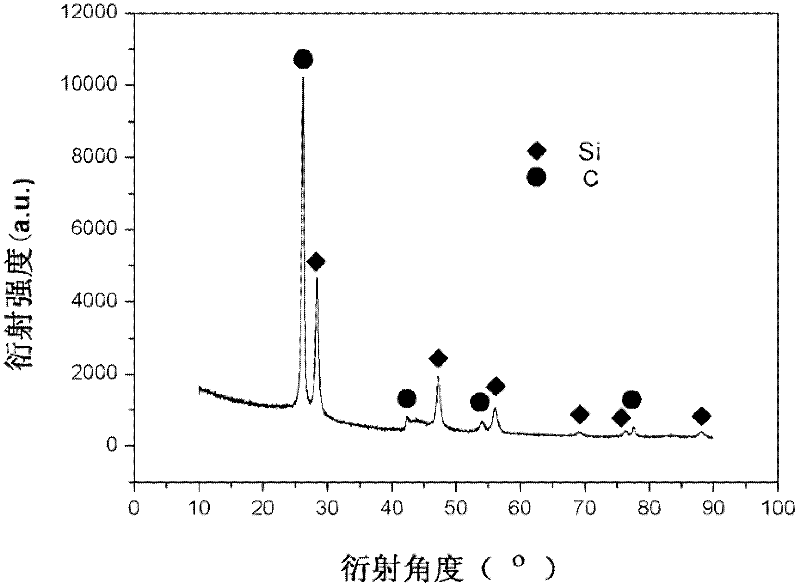

Image

Examples

Embodiment 1

[0038] 1. Add 10 grams of silicon powder with an average particle size of 150nm to a mixed solution of ethanol and water with a mass ratio of 9:1. The mass of the mixed solution is 40g; then at a frequency of 20KHz and a power density of 1.2W / cm 2 In the ultrasonic equipment, ultrasonically stirred for 30 minutes to form a uniform nano-silicon suspension.

[0039] 2. Slowly drop 2 grams of KH550 coupling agent γ-aminopropyltriethoxysilane into the nano-silicon suspension, and stir for 6 hours in a disperser with a rotation speed of 1000 rpm to obtain a modified nano-silicon suspension.

[0040] 3. Dissolve 6 grams of phenolic resin in 20 g of ethanol to form a phenolic resin solution, and slowly add the solution to the modified nano-silicon suspension, and stir for 3 hours at a speed of 1000 rpm; then add 40 grams of natural graphite, and continue stirring for 2 hours , to obtain a uniformly dispersed and mixed slurry. The slurry is dried.

[0041] 4. Heat treatment at a con...

Embodiment 2

[0051] 1. Add 10 grams of nano-silicon powder with an average particle size of 50nm to 200 grams of ethanol solution at a frequency of 40KHz and a power density of 1.2W / cm 2 In the ultrasonic equipment, ultrasonic 10min, forming a uniform nano-silicon suspension.

[0052] 2. Weigh ethanol and pure water and mix them in a mass ratio of 9:1. The quality of the mixed solution is 30 g. Add 3 grams of KH570 coupling agent γ-methacryloxypropyl trimethoxysilane, and add sodium carbonate to adjust the pH at Between 8 and 10, stir for 1 h in a disperser with a rotation speed of 500 rpm to obtain a silane solution. The silane solution was added dropwise into the nano-silicon suspension, and then stirred at a speed of 2000 rpm for 1 h to obtain a modified nano-silicon suspension.

[0053] 3. Dissolve 5 grams of pitch in 30 g of tetrahydrofuran to form a pitch suspension, and slowly add the suspension to the modified nano-silicon suspension, and stir for 1 hour in a disperser with a rota...

Embodiment 3

[0060] 1. Add 10 grams of nano-silicon powder with an average particle size of 500nm to a mixed solution of isopropanol and water with a mass ratio of 9:1. The quality of the mixed solution is 40 grams. The frequency is 10KHz and the power density is 1.2W. / cm 2 In the ultrasonic equipment, ultrasonically stirred for 60 minutes to form a uniform nano-silicon suspension.

[0061] 2. Weigh ethanol and pure water and mix them according to the mass ratio of 7:3. The quality of the mixed solution is 3g. Add 0.3 gram, add acetic acid to adjust the pH between 4 and 6, and stir in a disperser with a rotation speed of 500 rpm for 6 hours to obtain a silane solution. The silane solution was added dropwise to the nano-silicon suspension, and stirred in a disperser at a speed of 500 rpm for 6 hours to obtain a modified nano-silicon suspension.

[0062] Three, 50g citric acid is dissolved in 50g ethanol, forms citric acid solution, and this solution is slowly added in the modified nano-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com