Preparation method of flaky aluminate green phosphor

A green phosphor, aluminate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of uneven mixing, high temperature and long time of high-temperature solid-phase calcination, and achieve shortened calcination time and luminous performance. Excellent, the effect of reducing the phase temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

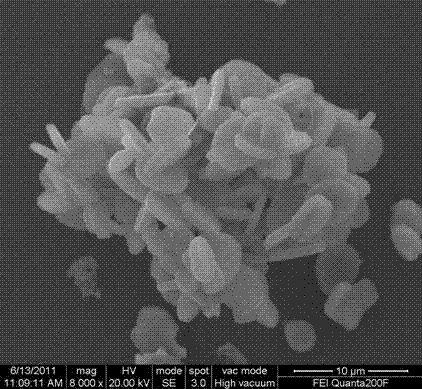

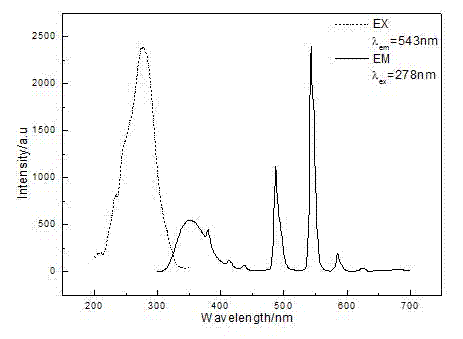

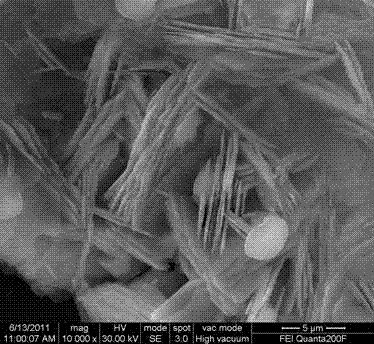

[0029] Weigh 0.2305 g CeO 2, Place in 30 ml 1:1 nitric acid solution, add 5 ml 30% hydrogen peroxide dropwise, stir while heating until completely dissolved, then weigh 0.1234 g Tb 4 o 7 , 0.08g MgO and 8.28 g Al(NO 3 ) 3 9H 2 O was added to it, heated and dissolved to obtain a mixed solution of nitrates. Add 0.8658 g NH to the mixed solution obtained above 4 F and 5.32 g of urea, heated and stirred to dissolve them, and concentrated to a nearly viscous state, then put them into a microwave oven to heat and ignite, and the combustion products were put into a nitrogen-hydrogen mixed gas (H 2 : 5 V%) in a tube atmosphere furnace at 1100 °C for 2 h. The product after heat treatment is washed, dried, ground and sieved to obtain Ce 0.67 Tb 0.33 MgAl 11 o 19 Phosphor.

Embodiment 2

[0031] Weigh 0.2305 g CeO 2, Place in 30 ml 1:1 nitric acid solution, add 5 ml 30% hydrogen peroxide dropwise, stir while heating until completely dissolved, then weigh 0.1234 g Tb 4 o 7 , 0.08g MgO and 0.594 g Al powder were added, heated and dissolved to obtain a nitrate mixed solution. Add 0.6734 g NH to the mixed solution obtained above 4 F and 4.56 g urea, heated and stirred to make it dissolve, and condensed to close to viscous state, continue heating to trigger self-propagating combustion reaction, and the combustion product is put into nitrogen-hydrogen mixed gas (H 2 : 5 V%) in a tube atmosphere furnace at 1100 °C for 2 h. The product after heat treatment is washed, dried, ground and sieved to obtain Ce 0.67 Tb 0.33 MgAl 11 o 19 Phosphor.

Embodiment 3

[0033] Weigh 0.2305 g CeO 2, Place in 30 ml 1:1 nitric acid solution, add 5 ml 30% hydrogen peroxide dropwise, stir while heating until completely dissolved, then weigh 0.1234 g Tb 4 o 7 , 0.08g MgO and 1.716 g Al(OH) 3 , added to it, heated and dissolved to obtain a mixed solution of nitrates. Add 0.8658 g NH to the mixed solution obtained above 4 F and 4.56 g urea, heated and stirred to make it dissolve, and concentrated to a nearly viscous state, then put it into a microwave oven to heat and ignite, and the combustion product was put into a nitrogen-hydrogen mixed gas (H 2 : 5 V%) in a tube atmosphere furnace at 1100 °C for 2 h. The product after heat treatment is washed, dried, ground and sieved to obtain Ce 0.67 Tb 0.33 MgAl 11 o 19 Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com