Antistatic stone paper for packing

A technology for stone paper and packaging, applied in the direction of fibrous fillers, dyed polymer organic compounds, etc., can solve the problems of white pollution, natural resource consumption, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

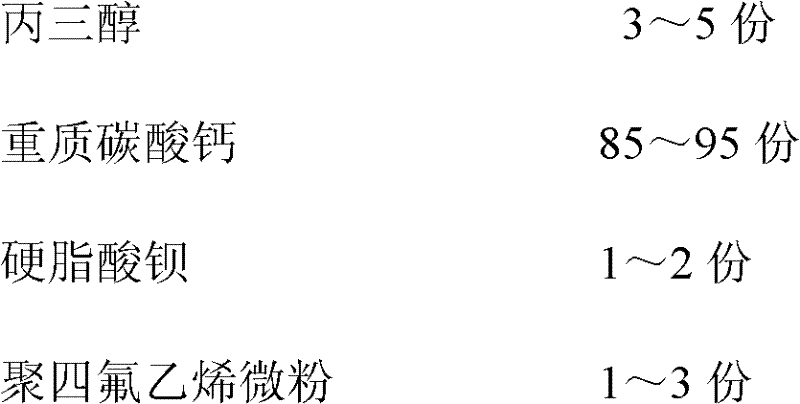

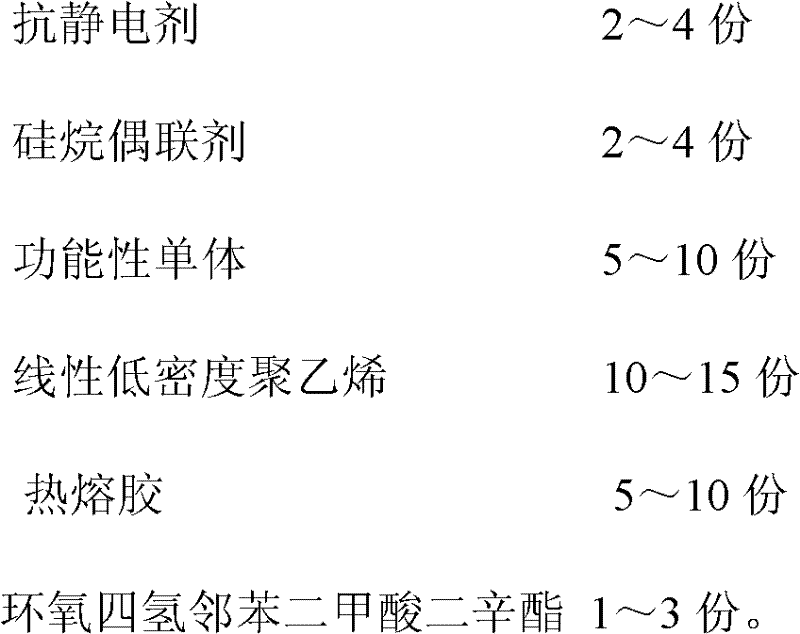

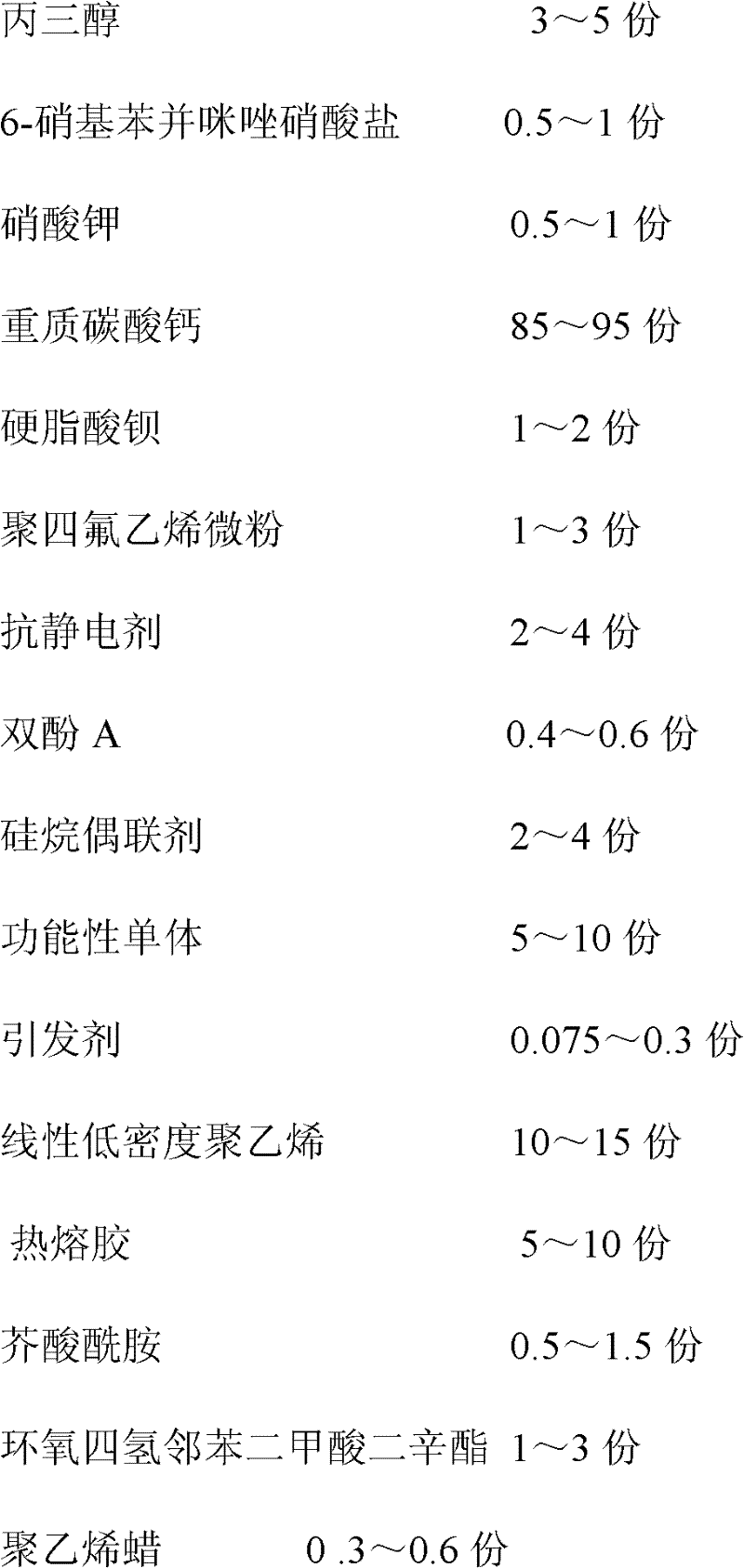

Method used

Image

Examples

Embodiment 1

[0023] 1. 3 parts of glycerol, 0.5 part of 6-nitrobenzimidazole nitrate, 0.5 part of potassium nitrate, 1 part of polytetrafluoroethylene micropowder, 0.4 part of bisphenol A, 2 parts of antistatic agent, 90 parts of heavy calcium carbonate 1 part of barium stearate, 2 parts of silane coupling agent, 5 parts of butyl acrylate, 0.075 parts of dimethyl azobisisobutyrate, 15 parts of linear low density polyethylene, 10 parts of hot melt adhesive, erucic acid 0.5 parts of amide, 0.5 parts of stearic acid, 1.5 parts of dioctyl epoxy tetrahydrophthalate, 1.5 parts of dioctyl sebacate, 0.6 parts of polyethylene wax, and 0.5 parts of sorbitan stearate.

[0024] 2. The preparation process of antistatic stone paper for packaging. First, prepare functional calcium carbonate for stone paper. The preparation process is as follows: a. Fully dissolve potassium nitrate in glycerin, and then dilute with absolute ethanol twice the weight of the solution Finally, add 6-nitrobenzimidazole nitrate...

Embodiment 2

[0027] 1. 4 parts of glycerol, 1 part of 6-nitrobenzimidazole nitrate, 0.75 parts of potassium nitrate, 2 parts of polytetrafluoroethylene micropowder, 0.5 parts of bisphenol A, 3 parts of antistatic agent, 90 parts of heavy calcium carbonate 1.5 parts of barium stearate, 3 parts of silane coupling agent, 6 parts of methyl acrylate, 0.12 parts of tert-butyl peroxybenzoate, 11 parts of linear low density polyethylene, 6 parts of hot melt adhesive, erucic acid 1 part of amide, 1 part of stearic acid, 1 part of dioctyl epoxy tetrahydrophthalate, 1 part of dioctyl sebacate, 0.4 part of polyethylene wax, 0.6 part of sorbitan stearate.

[0028] 2. The preparation process of antistatic stone paper for packaging. First, prepare functional calcium carbonate for stone paper. The preparation process is as follows: a. Fully dissolve potassium nitrate in glycerin, and then use absolute ethanol twice the weight of the solution After dilution, add 6-nitrobenzimidazole and nitrate, fully diss...

Embodiment 3

[0031] 1. 5 parts of glycerol, 0.75 parts of 6-nitrobenzimidazole nitrate, 1 part of potassium nitrate, 3 parts of polytetrafluoroethylene micropowder, 0.6 parts of bisphenol A, 4 parts of antistatic agent, 95 parts of heavy calcium carbonate 2 parts of barium stearate, 4 parts of silane coupling agent, 7 parts of vinyl acetate, 0.15 parts of dimethyl azobisisobutyrate, 12 parts of linear low density polyethylene, 7 parts of hot melt adhesive, erucic acid 1.5 parts of amide, 1.5 parts of stearic acid, 1.5 parts of dioctyl epoxy tetrahydrophthalate, 1.5 parts of dioctyl sebacate, 0.6 parts of polyethylene wax, and 0.7 parts of sorbitan stearate.

[0032] 2. The preparation process of antistatic stone paper for packaging. First, prepare functional calcium carbonate for stone paper. The preparation process is as follows: a. Fully dissolve potassium nitrate in glycerin, and then dilute with absolute ethanol twice the weight of the solution Finally, add 6-nitrobenzimidazole nitrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com