Method for preparing powdered resin

A powder resin and polymer technology, which is applied in the field of high-performance powder resin preparation, can solve the problems of poor processing effect and high energy consumption, and achieve the effects of improving the workshop environment, saving energy, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

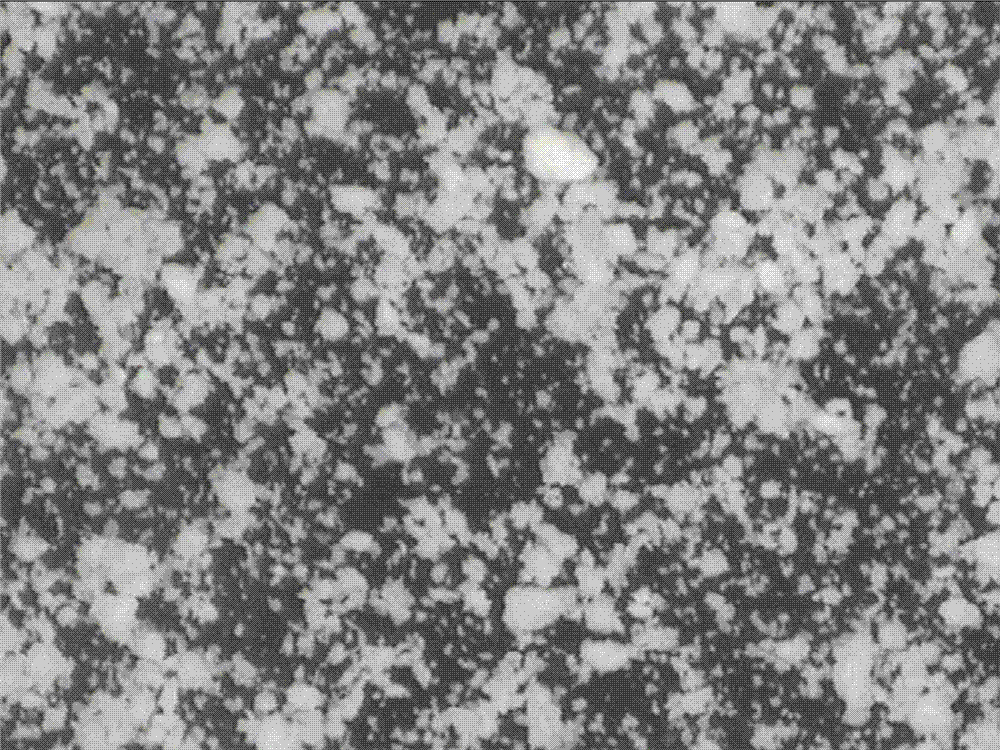

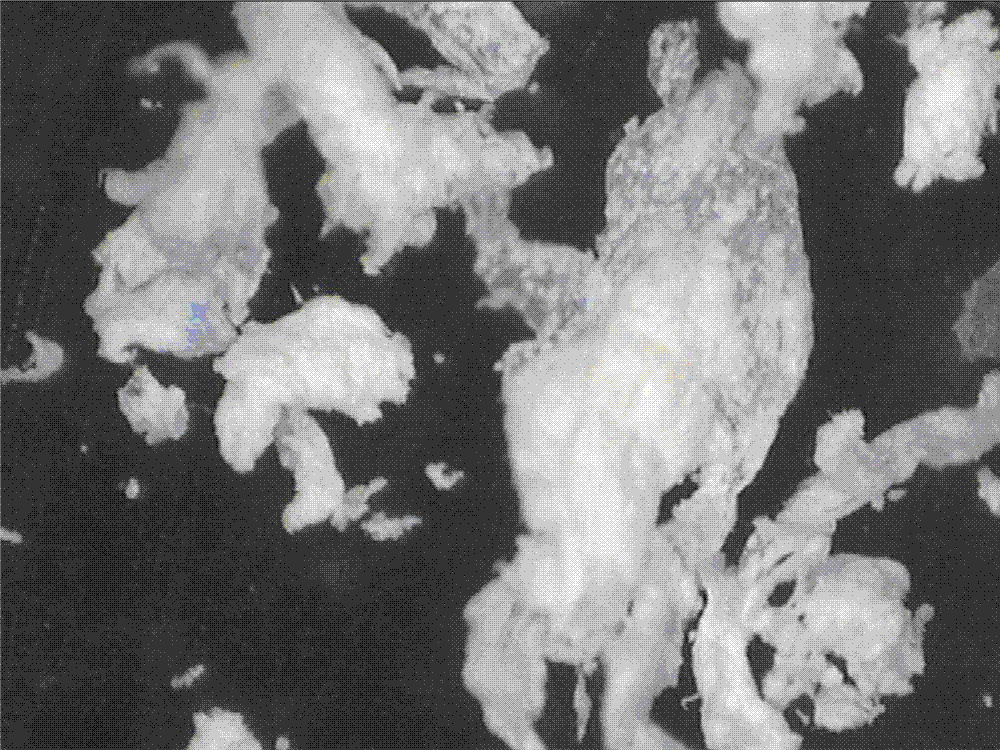

Image

Examples

Embodiment 1

[0023] Example 1 (about 15% solid content)

[0024] Polymerization process:

[0025] In a four-port reaction kettle equipped with a thermometer, a nitrogen pipe, a condensing separator, and an anchor stirrer, first add 50Kg of refined sulfolane, then add 6.67Kg of 4,4'-difluorobenzophenone and 3.303Kg Hydroquinone, when it is completely dissolved and the temperature rises to 80°C, add 3.498Kg (over 2%) Na 2 CO 3 , and then add 2Kg of xylene, stir and heat until the temperature rises to 150°C, the system starts to azeotrope, xylene and water condense in the water separator, the upper layer of xylene is refluxed, and the lower layer of water is continuously released, and the water is recovered to the theoretical When measuring, the xylene in the upper layer starts to be clear and transparent, and then continues to reflux for 20 minutes, and then starts to distill the xylene from the system. Continue to increase the viscosity. After 1.5 hours, stop the reaction after the visc...

Embodiment 2

[0029] Embodiment 2 (solid content about 30%)

[0030] Polymerization process:

[0031] In a four-port reaction kettle equipped with a thermometer, a nitrogen pipe, a condensing separator, and a paddle stirrer, first add 20Kg of refined sulfolane, and then add 6.67Kg of 4,4'-difluorobenzophenone and 3.303Kg Hydroquinone (available polymer 8.64Kg, solid content about 30%), when it is completely dissolved and the temperature rises to 80°C, add 3.498g (excess 2%) Na 2 CO 3 , then continue to heat up, add 2Kg of xylene, stir and heat, until the temperature rises to 150 ° C, the system starts to azeotrope, xylene and water condense in the water separator, the upper layer of xylene is refluxed, and the lower layer of water is continuously released. When the water is recovered to the theoretical amount, the xylene in the upper layer becomes clear and transparent, and the reflux continues for 20 minutes, and then the xylene starts to be evaporated from the system. The viscosity inc...

Embodiment 3

[0035] Example 3 (about 15% solid content) Polymerization process:

[0036] In a four-port reaction kettle equipped with a thermometer, a nitrogen pipe, a condensing water separator, and a propeller stirrer, first add 50Kg of refined sulfolane, then add 6.67Kg of 4,4'-difluorobenzophenone and 3.303Kg Hydroquinone (available polymer 8.64Kg, solid content about 15%), when it is completely dissolved and the temperature rises to 80°C, add 3.498Kg (excess 2%) Na 2 CO 3 , then continue to heat up, add 2Kg of xylene, stir and heat, until the temperature rises to 150 ° C, the system starts to azeotrope, xylene and water condense in the water separator, the upper layer of xylene is refluxed, and the lower layer of water is continuously released. When the water is recovered to the theoretical amount, the xylene in the upper layer becomes clear and transparent, and the reflux continues for 20 minutes, and then the xylene starts to be evaporated from the system. The polymerization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com