Automatic bursting point test instrument

A technology for testing instruments and breaking points, which is applied in the direction of explosiveness of materials, etc., can solve problems such as physical and mental health hazards, poor accuracy of test results, and poor judgment accuracy, so as to ensure physical and mental health, eliminate physical injuries, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

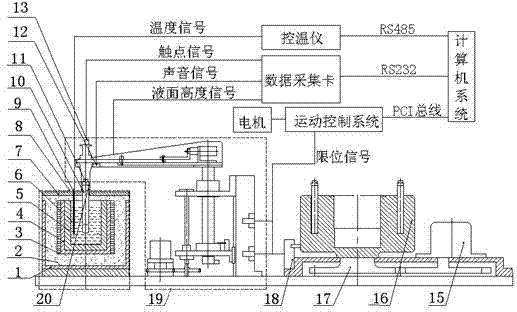

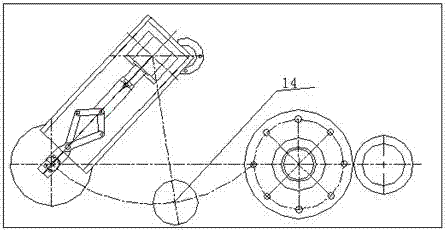

[0038] As shown in Figure 1, this embodiment provides a schematic structural diagram of an automated burst point testing instrument, including a temperature control system, a dedicated reactor, an automatic sampling mechanism and control system, and a signal and data acquisition and processing system.

[0039] The temperature control system mainly includes a temperature control instrument, a temperature sensor 9, and a heating furnace 8; the heating furnace 8 is composed of a liquid storage pool 5, a heat conduction layer 4, a heating layer 3, an insulation layer 2, an explosion-proof layer 1, a heating medium 6, and a furnace cover 7 composition.

[0040]The liquid holding pool 5 is a tank made of red copper. Red copper has corrosion resistance and strong thermal conductivity, and can withstand a certain explosion impact force. Inside the heat conducting layer 4 is a liquid holding pool 5, and a heating medium 6 is placed in the liquid holding pool 5 (Wood alloy bath liquid),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com