Drag-reducing abrasion-resisting solventless coating for pipeline as well as preparation method and application thereof

A solvent-free coating and pipeline technology, which is applied in the direction of pipeline damage/abrasion prevention, pipeline protection, anti-corrosion coating, etc. It can solve the problems of poor storage stability of operational coatings, high VOC content, inconvenient construction, etc., to eliminate physical injuries , reduce the use of ventilation equipment, good effect of drag reduction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Components of drag-reducing and wear-resistant solvent-free coatings for pipelines

[0065] Contains component A and component B, the mass percentage of each component raw material is:

[0066] Component A:

[0067] Epoxy resin 35.00%, using products from Hongchang Electronic Materials Co., Ltd. or Sinopec Yueyang Petrochemical Plant;

[0068]Toughening resin 6.50%, using the product of Shanghai Hongke Chemical Co., Ltd.;

[0069] Reactive diluent 5.60%; use Cardolite products;

[0070] Leveling agent 0.33%, using the product of BYK Chemical Auxiliary Company in Germany;

[0071] Defoamer 0.35%, using the product of German BYK Chemical Auxiliary Company;

[0072] Dispersant 0.60%, using the product of BYK Chemical Auxiliary Company in Germany;

[0073] Anti-sedimentation thickener 0.28%, using the product of Huaxia Auxiliary Company;

[0074] Zinc phosphate 6.50%, using the product of Shanghai Yipin Pigment Co., Ltd.;

[0075] Iron oxide red powder 12.00%, th...

Embodiment 2

[0095] (1) Components of drag-reducing and wear-resistant solvent-free coatings for pipelines

[0096] Contains component A and component B, the mass percentage of each component raw material is:

[0097] Component A:

[0098] Epoxy resin 38.00%;

[0099] Toughening Resin 8.00%

[0100] Active diluent 5.00%;

[0101] Leveling agent 0.30%;

[0102] Defoamer 0.32%;

[0103] Dispersant 0.50%;

[0104] Anti-settling thickener 0.42%

[0105] Zinc phosphate 5.00%;

[0106] Iron oxide red powder 10.00%;

[0107] White ceramic powder 4.55%

[0108] Aluminum tripolyphosphate 5.91%;

[0109] Component B:

[0110] Modified amine 12%;

[0111] Modified polyamide 10%;

[0112] When the coating is used, component A and component B are used together in a mass ratio of A:B =3.5:1.

[0113] (2) Specific steps of preparation

[0114] (with embodiment 1).

[0115] (3) Application method

[0116] (with embodiment 1).

Embodiment 3

[0118] (1) Components of drag-reducing and wear-resistant solvent-free coatings for pipelines

[0119] Contains component A and component B, the mass percentage of each component raw material is:

[0120] Component A:

[0121] Epoxy resin 32.00%;

[0122] Toughening resin 7.50%;

[0123] Reactive diluent 6.00%;

[0124] Leveling agent 0.35%;

[0125] Defoamer 0.40%;

[0126] Dispersant 0.65%;

[0127] Anti-settling thickener 0.50%;

[0128] Zinc phosphate 6.50%;

[0129] Iron oxide red powder 14.00%;

[0130] Aluminum tripolyphosphate 8.60%;

[0131] White ceramic powder 5.50%;

[0132] Component B:

[0133] Modified amine 14%;

[0134] Modified polyamide 4%

[0135] When the paint is used, component A and component B are used in conjunction with the mass ratio A:B = 4.5:1.

[0136] (2) Preparation method

[0137] (with embodiment 1).

[0138] (3) Application method

[0139] (with embodiment 1).

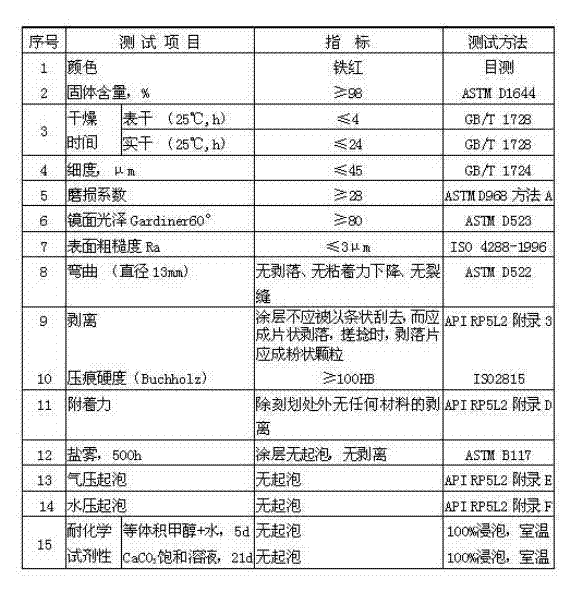

[0140] The drag-reducing and wear-resistant solvent-free paint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com