Super-hard material and preparation method thereof

A technology for superhard materials and alloys, applied in the field of superhard materials and their preparation, can solve the problems of insufficient toughness, temperature resistance, wear resistance, corrosion resistance, and anti-stickiness, and achieve simple manufacturing, improved strength and Fracture toughness, effect for a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Simultaneously, the present invention proposes a kind of preparation method of superhard material, and this method comprises the following steps:

[0030] Step 1: Prepare a mixed alloy, mix powders of different components of the mixed alloy according to the designed ratio, and the mixed alloy is at least 5 combinations of aluminum, chromium, copper, iron, manganese, titanium, vanadium, cobalt, nickel and carbon The obtained alloy, where each element accounts for 5 to 35 mol% of the mixed alloy, is mixed and ball milled to fully mix the different components to form a mixed alloy powder, and the ball milling time is 10-20 hours;

[0031] Step 2: Mix at least one ceramic phase powder and mixed alloy powder to form a mixture, the ceramic phase is tungsten carbide or titanium carbide, the weight percentage of ceramic phase powder and mixed alloy powder is: ceramic phase powder: 80-85%; mixed alloy : 15-20%;

[0032] Step 3: The mixture is pressed and sintered to form a supe...

Embodiment 1

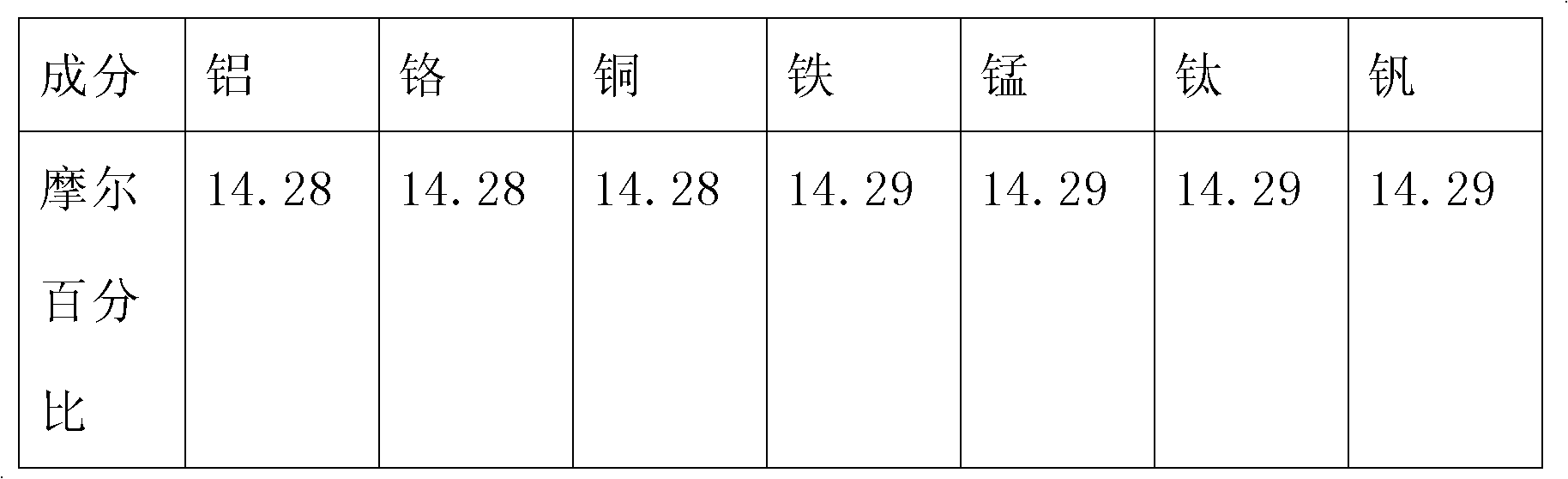

[0034] In this example, a variety of pure metal or alloy powders are mechanically milled to form mixed alloy powders, and then the mixed alloys and tungsten carbide powders are mixed and ball milled in different proportions to make them uniformly mixed composite material powders. . Then the uniform tungsten carbide-mixed alloy mixed powder is pressed and sintered at high temperature to make a superhard material sintered body, and finally the sintered body is tested and analyzed. In this embodiment, seven kinds of pure metal powders of aluminum, chromium, copper, iron, manganese, titanium and vanadium are used to make multivariate high-entropy alloy powders, and the contents are as follows:

[0035]

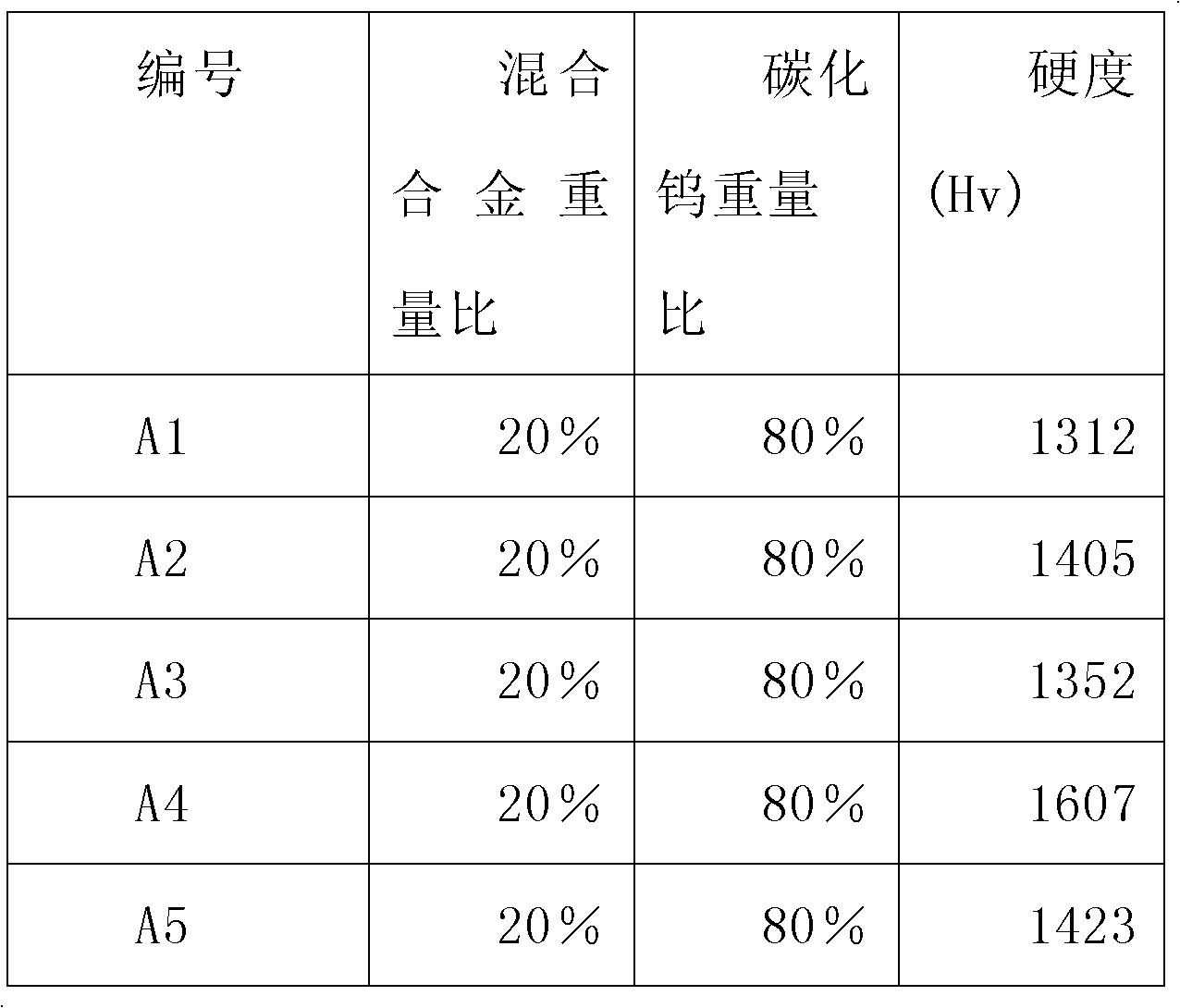

[0036] The prepared powder is ball milled for 18 hours to obtain a mixed alloy powder, and then mixed with tungsten carbide powder according to the ratio in the table below, mechanically ball milled and pressed and sintered. The hardness of the sintered material is shown in the...

Embodiment 2

[0040] In this example, six kinds of pure metal or alloy powders are mechanically milled to form mixed alloy powders, and then the mixed alloys and tungsten carbide powders are mixed and ball milled in different proportions to make them uniformly mixed composite material powders. . Then the uniform tungsten carbide-mixed alloy mixed powder is pressed and sintered at high temperature to make a superhard material sintered body, and finally the sintered body is tested and analyzed. In this embodiment, seven kinds of pure metal powders of aluminum, chromium, copper, iron, manganese, titanium and vanadium are used to make multivariate high-entropy alloy powders, and their contents are shown in the following table:

[0041]

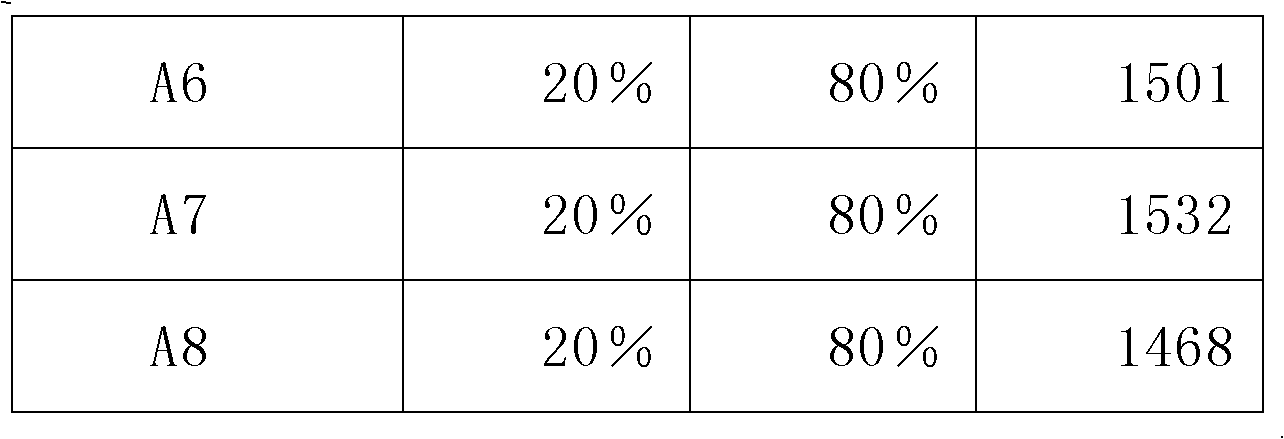

[0042] After the prepared powder is ball milled, it is mixed with tungsten carbide powder according to the ratio in the table below, mechanically ball milled and pressed and sintered. The hardness of the sintered material is shown in the table below. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com