Antistatic graphite composite polyamide plastics with high heat radiation and preparation method thereof

A composite polyamide, high heat dissipation technology, applied in the field of high heat dissipation graphite composite polyamide plastic and its preparation, can solve the problems of improving the shape design of the radiator and the yield, the long-term oxidation heat dissipation performance is not very good, and it is not good for the radiator Miniaturization and production problems, to achieve the effect of promoting the development of miniaturization, compact structure, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

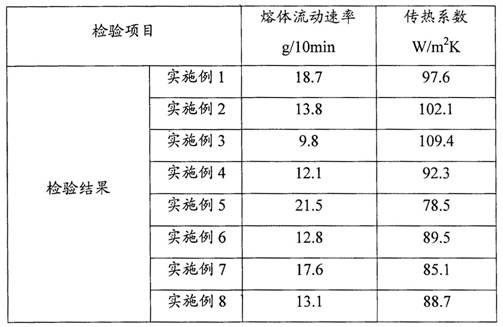

Examples

Embodiment 1

[0034] (1) First, add 6kg of lithium silicate, 6kg of sodium silicate and 10kg of water into a high-speed mixer and stir to obtain an aqueous silicate solution. Next, add 30kg of graphite, 3kg of bismaleimide and 3kg of hexagonal boron nitride into the high-speed mixer and mix them with the silicate aqueous solution in turn, stir at a high speed, the stirring rate is 800r / min, and the stirring time is 6min; then the mixer is heated to Keep stirring at 120°C for 15 minutes, dry the moisture in the material, and cool to 82°C to obtain a mixed powder.

[0035] (2) Add 1 kg of silane coupling agent to the mixed powder, stir at high speed for 3 minutes, add 50 kg of polyamide, 0.5 kg of antioxidant 168 and 0.5 kg of antioxidant 1010 into the high-speed mixer and mix according to the above ratio, and stir on the high-speed mixer 3min, the stirring speed was 800 r / min, and the mixture was obtained.

[0036](3) Extrusion molding, the temperature of the twin-screw extruder is 250°C to...

Embodiment 2

[0041] (1) First, add 5kg of lithium silicate, 10kg of sodium silicate and 12kg of water into a high-speed mixer and stir to obtain an aqueous silicate solution; secondly, mix 35kg of graphite, 2kg of bismaleimide and 2kg of hexagonal boron nitride in sequence Add it into a high-speed mixer to mix with silicate aqueous solution, stir at a high speed, the stirring rate is 600r / min, and the stirring time is 8min; then heat the mixer to 120°C, continue stirring for 20min, dry the moisture in the material, and cool it to 75 °C, a mixed powder was obtained.

[0042] (2) Add 0.5kg of silane coupling agent to the mixed powder, stir at high speed for 2 minutes, add 45kg of polyamide, 0.25kg of antioxidant 168 and 0.25kg of antioxidant 1010 into a high-speed mixer and mix, and stir on a high-speed mixer for 2 minutes. The stirring rate was 600 r / min to obtain a mixture.

[0043] (3) Extrusion molding, the temperature of the twin-screw extruder is 260°C to 270°C, and the screw speed is...

Embodiment 3

[0048] (1) First, add 10kg of lithium silicate and 8kg of water into a high-speed mixer and stir to obtain a silicate aqueous solution; secondly, add 40kg of graphite, 3kg of bismaleimide and 4kg of hexagonal boron nitride into a high-speed mixer in sequence and mix with Mix the silicate aqueous solution, stir at a high speed, the stirring rate is 700 r / min, and the stirring time is 7 minutes; then heat the mixer to 115°C, continue stirring for 18 minutes, dry the moisture in the material, and cool it to 82°C to obtain a mixed powder .

[0049] (2) Add 1kg of silane coupling agent to the mixed powder, stir at high speed for 4min, add 40kg of polyamide, 1kg of antioxidant 168 and 1kg of antioxidant 1010 into the high-speed mixer and mix them, stir for 5min on the high-speed mixer, and the stirring speed is 700 r / min to obtain a mixture.

[0050] (3) Extrusion molding, the temperature of the twin-screw extruder is 270°C to 280°C, and the screw speed is 150r / min; the mixture is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com