Preparation method of epoxy resin-based polymer dispersion liquid crystal film material

A technology for dispersing liquid crystals and epoxy resins, applied in liquid crystal materials, epoxy resin glue, chemical instruments and methods, etc., can solve the problems of poor toughness of PDLC films, affect product economic benefits, reduce product yield, etc., and achieve improved adhesion Junction properties, reduced off-state transmittance, and enhanced peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

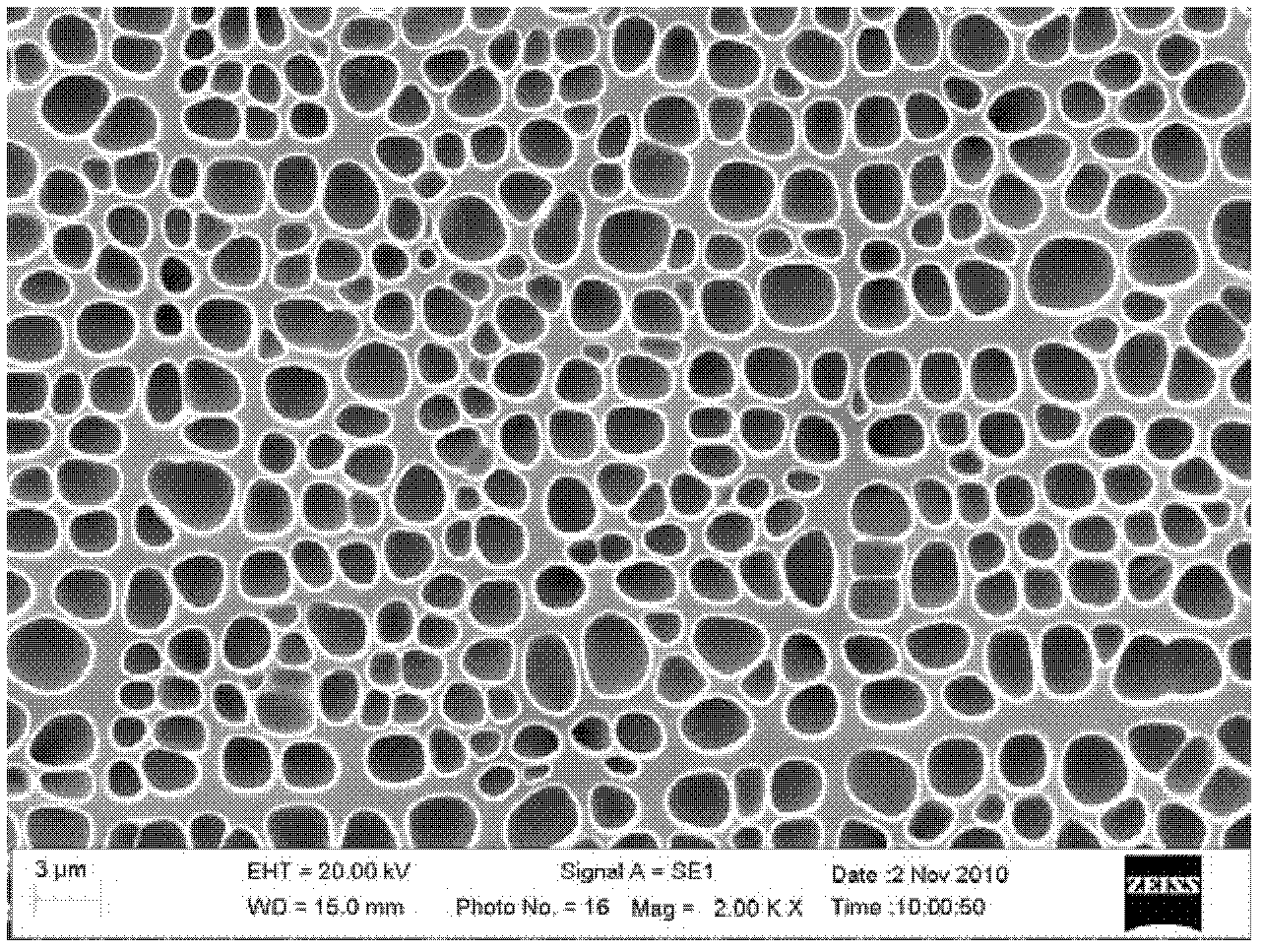

[0022] The selected thermal polymerization monomer is aliphatic glycidyl ether epoxy resin-polyethylene glycol diglycidyl ether EGDE (Anhui Hengyuan Chemical Co., Ltd.), liquid crystal SLC1717 (Shijiazhuang Yongsheng Huaqing Liquid Crystal Co., Ltd.), curing agent 1, 8-Diamino-3, 6-dioxaoctane EDBEA (Alfa Aesar), glass beads (SP-200, Sekisui chemical Co. LTD.). The mass ratio of EGDE / curing agent / liquid crystal is 48.0 / 12.0 / 40.0. The mixture of thermally polymerized monomer, liquid crystal and curing agent is evenly sandwiched between two conductive plastic films coated with ITO, and cured in a drying oven at a constant temperature of 70°C. 8 After hours, the PDLC film to be prepared is obtained. figure 1 This is a scanning electron microscope picture of the PDLC film prepared in Example 1.

[0023]

Embodiment 2

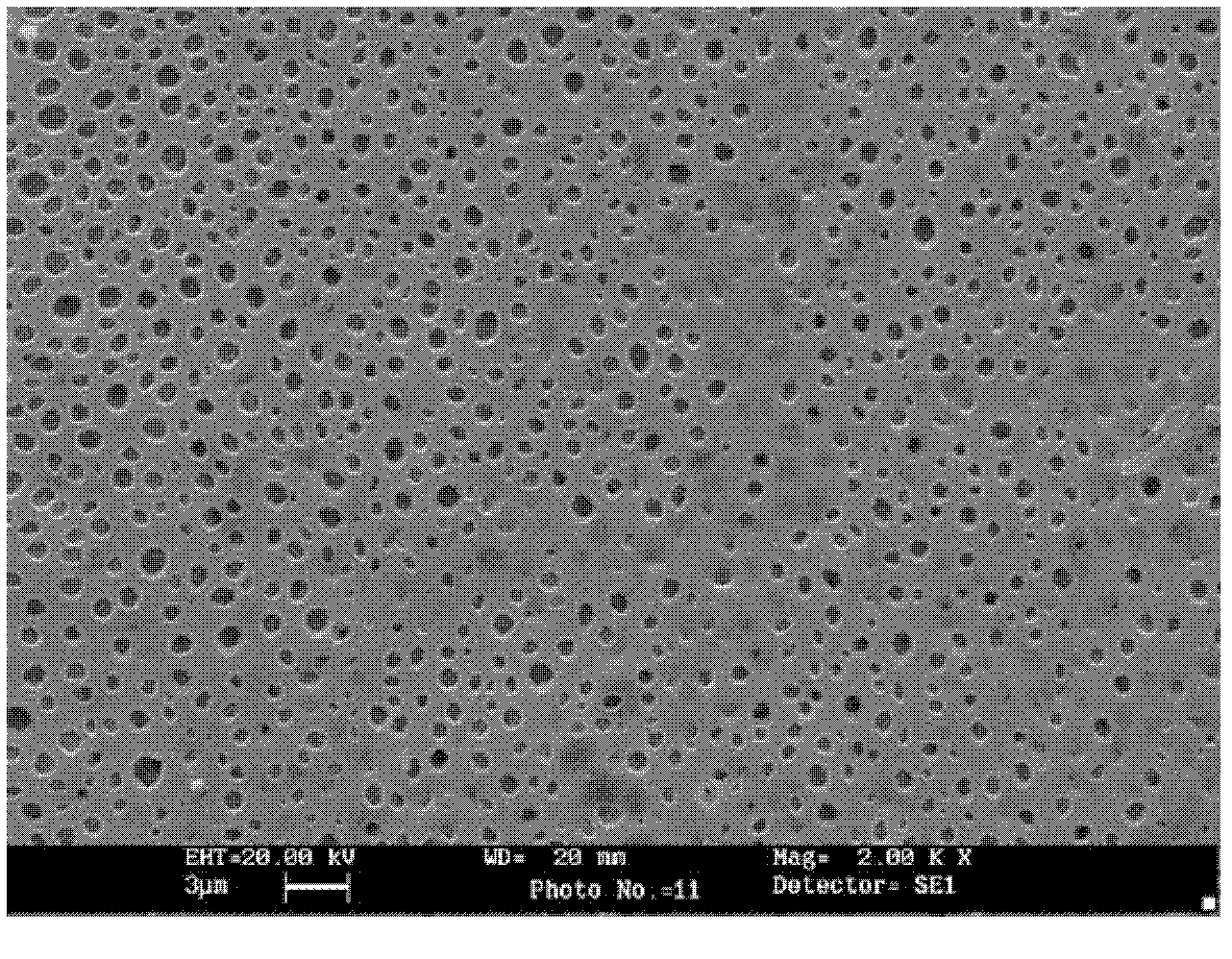

[0025] The selected thermal polymerization monomer is aliphatic glycidyl ether epoxy resin——polyethylene glycol diglycidyl ether EGDE, trimethylolpropane triglycidyl ether TMPTGE (Nanjing Kangmanlin Chemical Industry Co., Ltd.), liquid crystal SLC1717, curing agent 1, 8-Diamino-3, 6-dioxaoctane EDBEA (Alfa Aesar), glass beads (SP-200, Sekisui chemical Co. LTD.). The mass ratio of EGDE / TMPTGE / curing agent / liquid crystal is 20.0 / 25.0 / 15.0 / 40.0 to be evenly mixed. The mixture of thermally polymerized monomer, liquid crystal, and curing agent is uniformly sandwiched between two conductive plastic films plated with ITO, and cured in a drying oven at a constant temperature of 80° C. for 6 hours to obtain the PDLC film to be prepared. figure 2 This is a scanning electron micrograph of the PDLC film prepared in Example 2.

[0026]

Embodiment 3

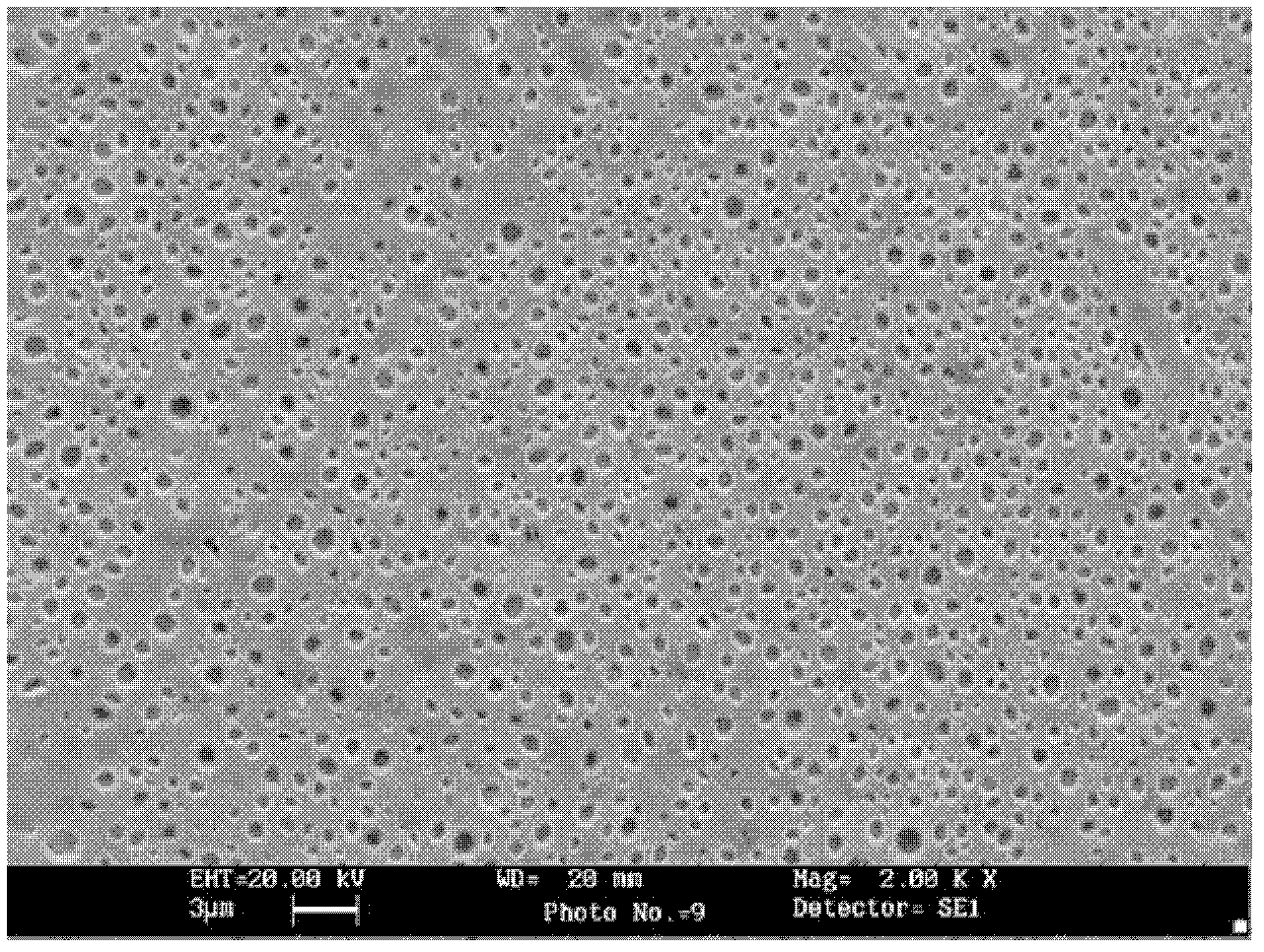

[0028] The selected thermal polymerization monomer is aliphatic glycidyl ether epoxy resin-polyethylene glycol diglycidyl ether EGDE, pentaerythritol glycidyl ether PERTGE (Ruiying Pharmaceutical Co., Ltd.), liquid crystal SLC1717, curing agent 1, 8-two Amino-3, 6-dioxa octane EDBEA (Alfa Aesar), glass beads (SP-200, Sekisui chemical Co. LTD.). The mass ratio of EGDE / PERTGE / curing agent / liquid crystal is 25.0 / 17.0 / 18.0 / 40.0 to be evenly mixed. The mixture of thermally polymerized monomer, liquid crystal, and curing agent is uniformly sandwiched between two conductive plastic films plated with ITO, and cured in a drying oven at a constant temperature of 80° C. for 6 hours to obtain the PDLC film to be prepared. image 3 This is a scanning electron micrograph of the PDLC film prepared in Example 3.

[0029]

[0030] Figure 4 The electro-optical performance curve of the PDLC film prepared in all the examples. Curve 1 is the electro-optical performance curve of the PDLC film prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com