Method for manufacturing micro-electronic part by using nanometer materials with multilevel heterostructure

A technology of microelectronic devices and heterostructures, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of life and stability that cannot meet the needs of the electronics industry, low electron mobility applications and development, complex processing processes and other problems, to achieve the effect of easy promotion and application, low production cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In a 50ml Erlenmeyer flask, add 0.45g polyvinylpyrrolidone (PVP) into 7.5ml ethanol, stir at room temperature for 8h until the solution is completely clear.

[0055] Take another 10ml Erlenmeyer flask, add 1.5g butyl titanate, 3ml ethanol and 3ml acetic acid in sequence, stir vigorously at room temperature for 10min until completely dissolved. The polymer solution was mixed with the metal salt solution and stirred at room temperature for 1 hour.

[0056]Put the mixed solution into the spinneret of the electrospinning equipment, the inner diameter of the spinneret head is 1mm, the aluminum sleeve is used as the anode, and the parallel aluminum strips (distance 2.2cm) are used as the cathode to accept the product, and the distance between the two poles is 20 cm, and an applied voltage of 10 kV was used for electrospinning. In this way, parallel arrangement of polyvinylpyrrolidone-containing nanofibers will be obtained between the two parallel aluminum strips of the catho...

Embodiment 2

[0063] Solution preparation and spinning process are consistent with Example 1.

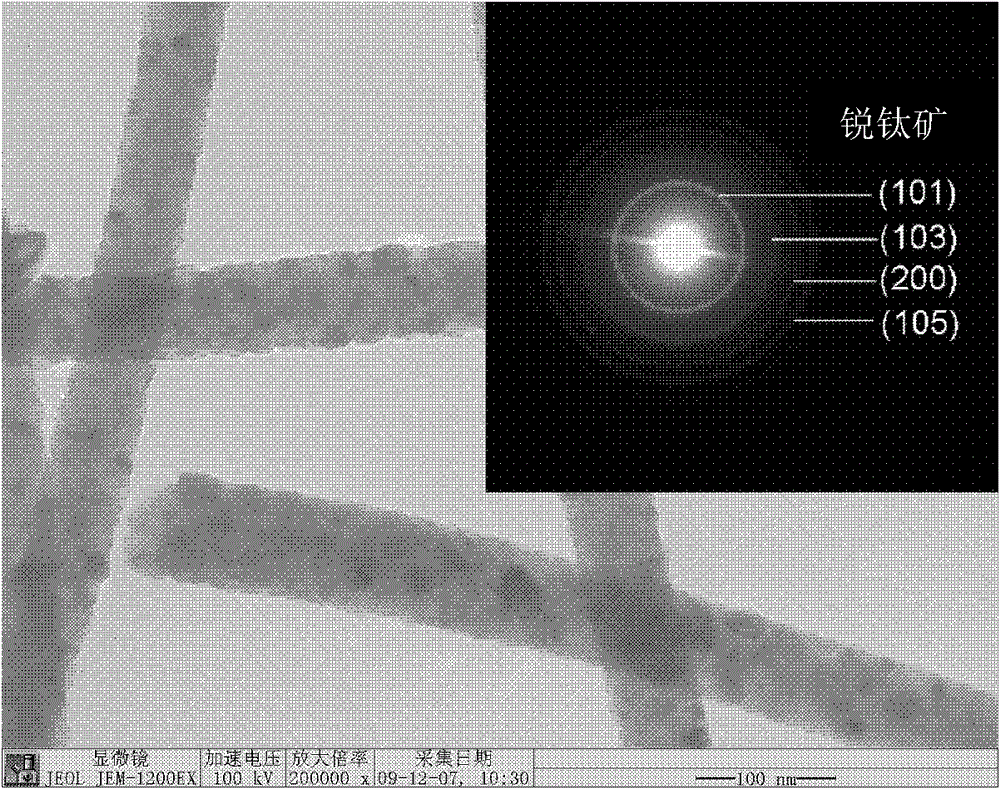

[0064] The quartz wafer substrate was ultrasonically cleaned in ethanol, acetone and deionized water in order to collect the aligned fibers between the two aluminum strips, placed in the air for 12 hours, then placed in a muffle furnace, and slowly heated to 450°C for sintering at a constant temperature for 5 The macromolecule PVP was completely removed within hours, and titanium dioxide nanofibers were obtained. Take a 50ml beaker, add 15ml of water, 15ml of concentrated hydrochloric acid and 0.5g of butyl titanate in sequence, stir evenly until the solution is clear, transfer it together with the quartz sheet attached with parallel anatase titanium dioxide nanofibers to a 40ml hydrothermal reaction kettle, Place in a constant temperature oven at 150°C for 3 hours, take out the quartz slices, wash and dry them. The rutile nanorods on the fiber surface are significantly shorter and thinner than ...

Embodiment 3

[0067] Solution preparation and spinning process are consistent with Example 1.

[0068] The quartz wafer substrate was ultrasonically cleaned in ethanol, acetone and deionized water in order to collect the aligned fibers between the two aluminum strips, placed in the air for 12 hours, then placed in a muffle furnace, and slowly heated to 450°C for sintering at a constant temperature for 5 The macromolecule PVP was completely removed within hours, and titanium dioxide nanofibers were obtained. Take a 50ml beaker, add 15ml of water, 15ml of concentrated hydrochloric acid and 0.5g of butyl titanate in sequence, stir evenly until the solution is clear, transfer it together with the quartz sheet attached with parallel anatase titanium dioxide nanofibers to a 40ml hydrothermal reaction kettle, Place in a constant temperature oven at 150°C for 2 hours, take out the quartz slices, wash and dry them. The arrangement of rutile nanorods on the fiber surface is sparser, obviously shorte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com