Aluminum-based material with integrated radiation and neutron shielding effect

A technology of comprehensive shielding and aluminum-based materials, applied in the field of aluminum-based shielding materials and their preparation, can solve problems such as poor mechanical strength and heat resistance, low boron content, and defects in radiation shielding effects, and achieve the effect of improving shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

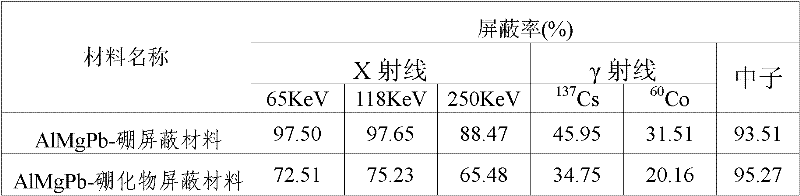

[0014] Example 1: 48% Al, 33.6% Pb and 14.4% Mg were added in a melting furnace, and 4.0% boron was added. At this time, the mass percentage of the AlMgPb aluminum-based alloy in the entire shielding material is 96%; Stir for 2 to 5 minutes to fully react and form each component. The high-strength AlMgPb-boron aluminum-based ray / neutron shielding material is prepared by casting. The test results are as follows:

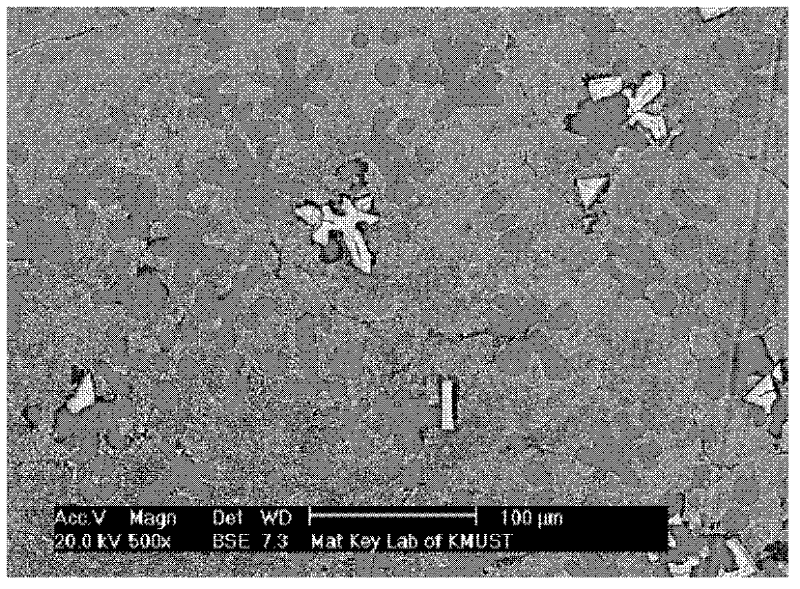

[0015] ①Microstructure characteristics: After surface treatment of the sample (grinding→polishing→corrosion), the scanning electron microscope (model XL30ESEM-TMP) was used to observe and analyze the microstructure characteristics of the sample, such as figure 1 shown. The test shows that the distribution of the alloy structure is uniform, and the interfacial bonding of each phase is in good condition.

[0016] ②Tensile strength test: Prepare the test sample bar and carry out the tensile strength test on the tensile mechanical testing machine. The test results sho...

Embodiment 2

[0019] Example 2: 50.6% of Al, 27.6% of Mg and 13.8% of Pb are added in a melting furnace, and then 8% of borides are added. At this time, the mass percentage of AlMgPb aluminum-based alloy in the entire shielding material is 92%; the boride is 8%; the mass percentage of each component in the AlMgPb alloy is: Mg 30%, Pb 15%, Al 55%. Stir for 2 to 5 minutes to fully react and form each component. Casting is prepared into a high-strength AlMgPb-boride aluminum-based ray / neutron shielding material. The test results are as follows:

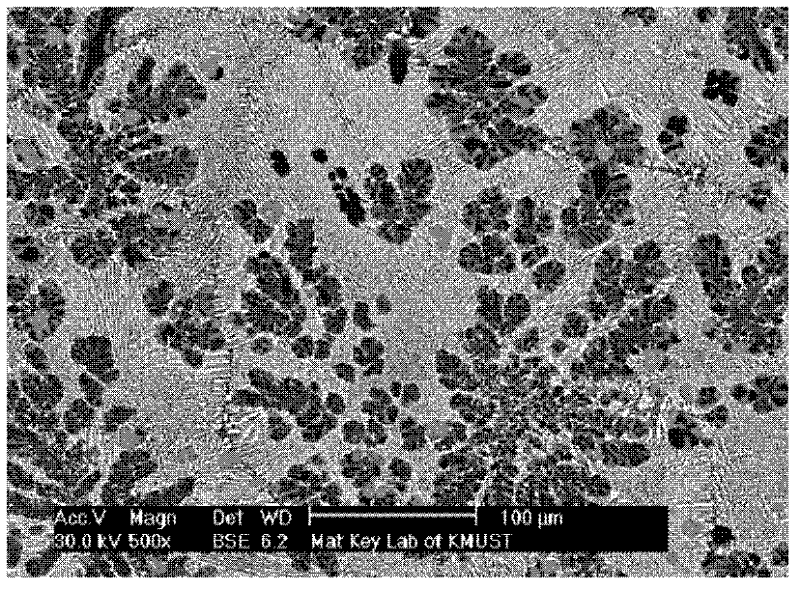

[0020] ①Microstructure characteristics: After surface treatment of the sample (grinding→polishing→corrosion), the scanning electron microscope (model XL30ESEM-TMP) was used to observe and analyze the microstructure characteristics of the sample, such as figure 2 shown. The test shows that the distribution of the alloy structure is uniform, and the interfacial bonding of each phase is in good condition.

[0021] ②Tensile strength test: Prepare the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com