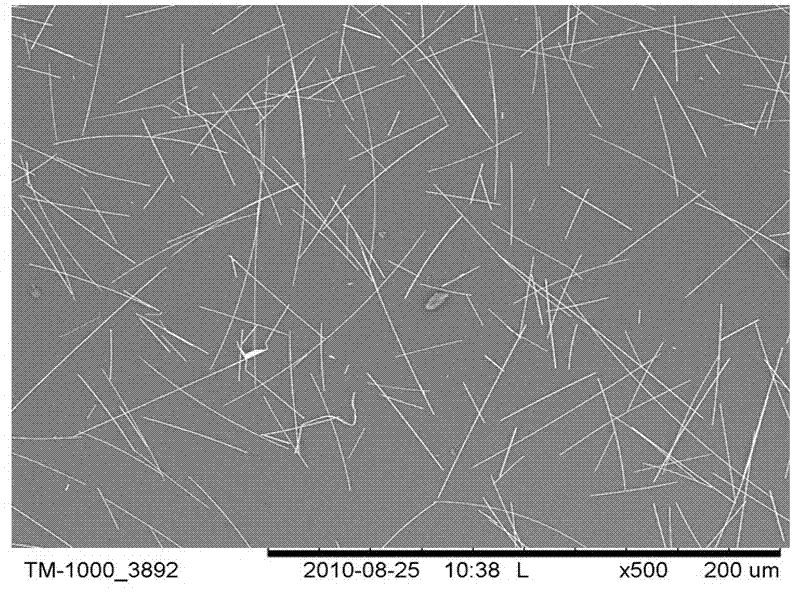

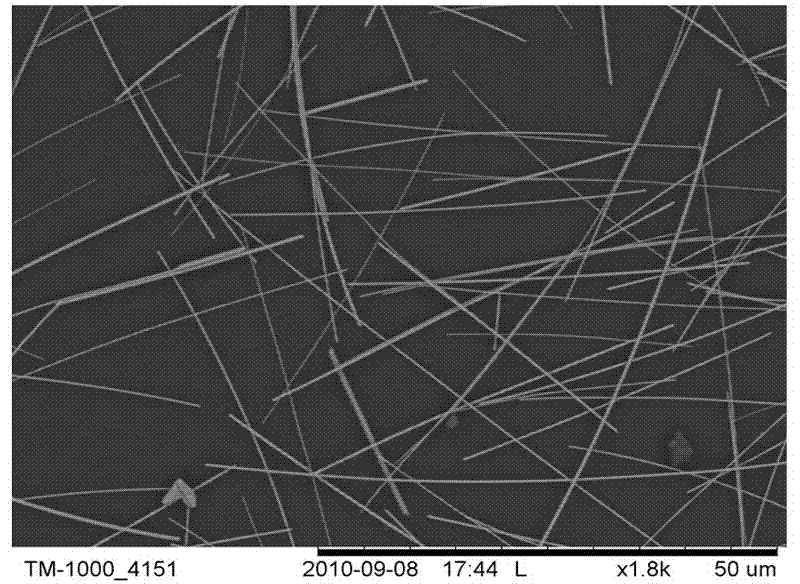

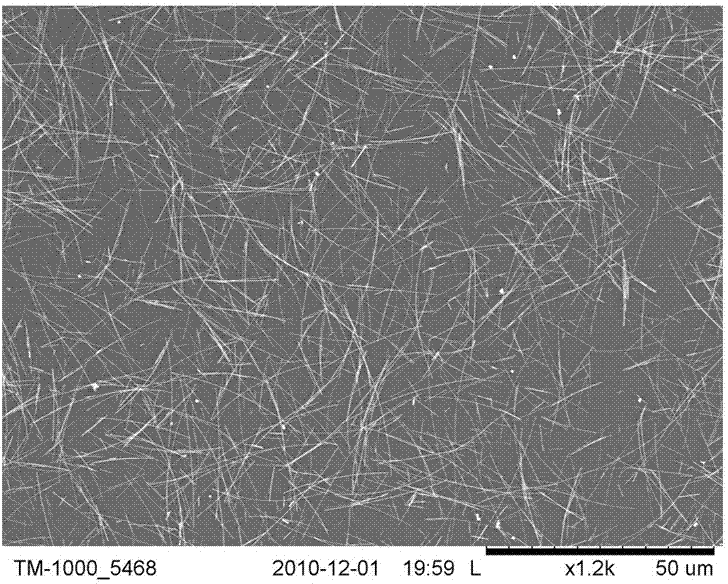

A method for rapid and large-scale preparation of silver nanowires with high aspect ratio

A high aspect ratio, nano silver wire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of small aspect ratio, long reaction time and poor conductivity of silver nanowires, and achieve high concentration The effect of rapid mass preparation, simple preparation method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Carry out according to preparation process: (1) the silver nitrate of 0.1mol is joined in 480ml ethylene glycol, the solution reaction system containing silver ion is prepared, then the polyvinylpyrrolidone of 0.3mol that K value is 30 joins this solution system , prepare a solution system containing silver ions; (2) add 0.1mmol of NaCl powder to 20ml ethylene glycol, stir evenly to obtain a clear solution system; (3) add the solution to the prepared solution in step (1) Add dropwise the ethylene glycol solution of 20mlNaCl obtained in step (2) and concentrated nitric acid 0.01mol, the molar concentration of nitric acid in the solution is 0.02mol / L, the pH value of the solution is 1.7, continue to stir evenly, and obtain the reaction precursor, (4 ) using the method of microwave irradiation, irradiating the obtained precursor under 400W microwave for 14min to obtain a silver nanowire material with high aspect ratio, and centrifuging and washing the solution obtained afte...

Embodiment 2

[0058] Carry out according to preparation process: (1) the silver acetate of 0.1mol is joined in 480ml ethylene glycol, prepare the solution reaction system containing silver ion, then the polyvinylpyrrolidone of 0.3mol with K value 30 joins this solution system In, prepare the solution system containing silver ion; (2) the MnCl of 0.5mmol 2 Add the powder into 20ml of ethylene glycol and stir evenly to obtain a clear solution system; (3) Add 20ml of MnCl prepared in step (2) dropwise to the solution prepared in step (1) 2 The ethylene glycol solution and concentrated nitric acid 0.0125mol, the molar concentration of nitric acid in the solution is 0.025mol / L, the pH value of the solution is 1.6, continue to stir evenly, and obtain the reaction precursor, (4) adopt the method of microwave irradiation, will get This precursor was irradiated under 480W microwave, and the silver nanowire material with high aspect ratio was obtained for 15 minutes. The solution obtained after micro...

Embodiment 3

[0060] Carry out according to preparation process: (1) the silver nitrate of 0.05mol is joined in the ethylene glycol of 240ml, prepares the solution reaction system containing silver ion, then the polyvinylpyrrolidone of 0.2mol of K value is 30 joins this solution system In, prepare the solution system containing silver ion; (2) the MnCl of 0.2mmol 2 Add the powder into 10ml of ethylene glycol and stir evenly to obtain a clear solution system; (3) Add 10ml of MnCl prepared in step (2) dropwise to the solution prepared in step (1) 2 ethylene glycol solution and concentrated nitric acid 0.0125mol, the molar concentration of nitric acid in the solution is 0.05mol / L, the pH value of the solution is 1.3, continue to stir evenly, and obtain the reaction precursor (4) adopt the method of microwave irradiation, the obtained The precursor was irradiated under 320W microwave for 17min to obtain a silver nanowire material with a high aspect ratio, and the solution obtained after microwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com