Method for preparing magnesium alloy material

A magnesium alloy and alloy technology, applied in the field of preparation of magnesium alloy materials, can solve problems such as easy coarsening, unsatisfactory mechanical properties and corrosion resistance at room temperature, and difficult to meet, and achieve the effect of improving mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

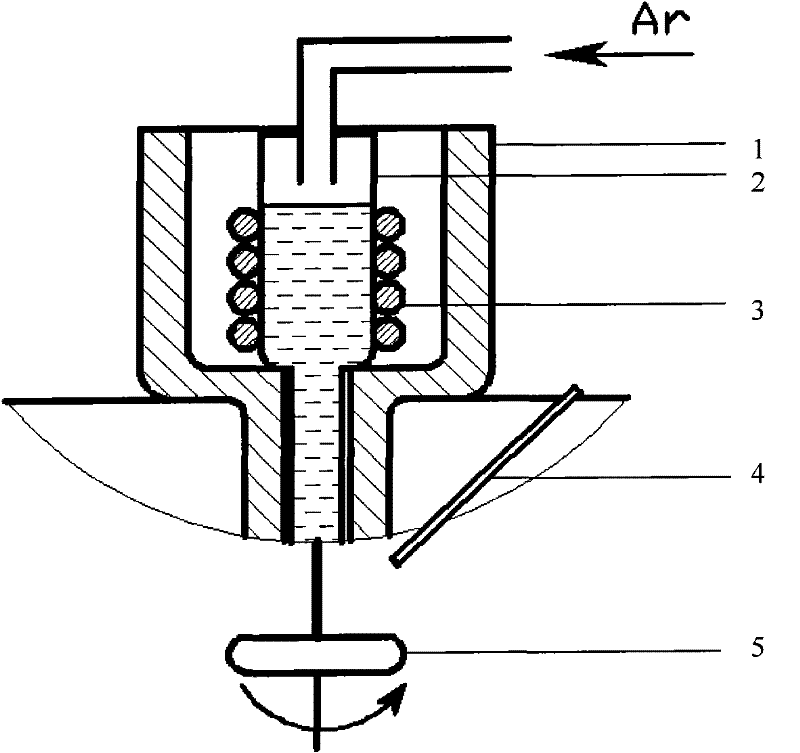

[0022] 6g Mg 94 Zn 6 The medical degradable implant alloy is placed in a quartz tube with a diameter of 15mm and a nozzle width of 0.6mm, and the equipment is vacuumed to 5.0×10 -3 Pa back filled with argon gas of 20kPa and heated by high-frequency induction heating device. When the alloy is melted and overheated at about 50°C, use 5kPa argon to spray the molten liquid onto the high-speed copper quenching plate. The surface line speed is 100m / s. Open, spray argon gas through the gas nozzles installed around the disk to accelerate cooling, such as figure 1 As shown, the powder is finally molded by compression molding. The yield strength of the rapidly solidified magnesium-zinc alloy at 60°C is 120MPa higher than that of the alloy with the same composition after casting and forging, and the tensile strength is 60MPa higher, and it also has good plasticity.

Embodiment 2

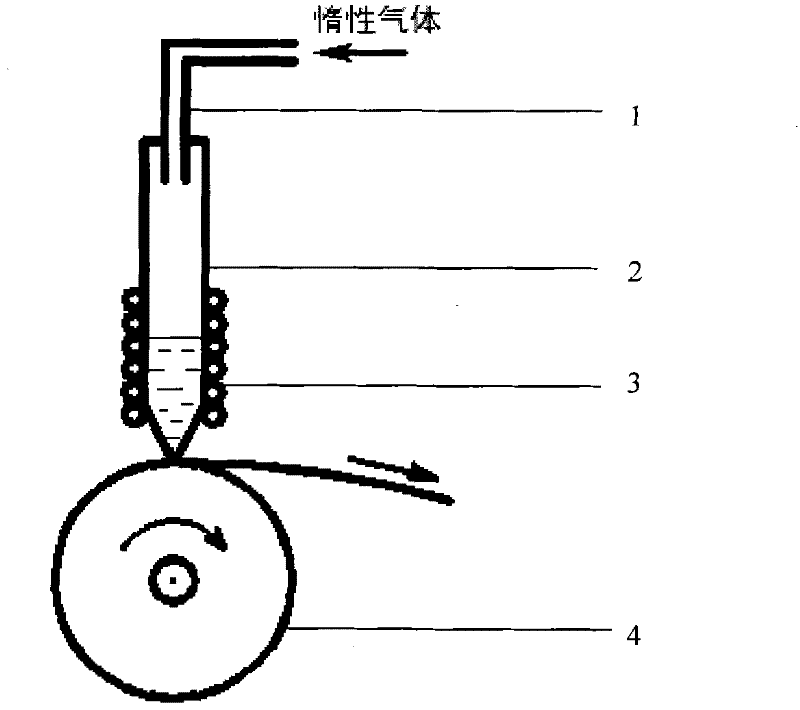

[0024] Put 5g of Mg-5Zn-0.5Ca medical degradable implant alloy into a quartz tube with a diameter of 15mm and a nozzle width of 0.6mm, and the equipment is vacuumed to 5.0×10 -3 After Pa, it is reversely filled with 20kPa helium and heated by a high-frequency induction heating device. After the alloy is melted and superheated at about 50°C, spray the molten liquid onto the surface of the high-speed running copper roller with 5kPa helium gas. The copper roller rotates at 2500rpm and the diameter of the copper roller is 220mm. direction to form a thin strip with a thickness of 90 μm and a width of 5 mm, such as figure 2 shown. The tensile yield strength of the Mg-5Zn-0.5Ca thin strip is 490-520MPa, and the theoretical expected value can reach 630MPa, which has high strength and high ductility.

Embodiment 3

[0026] Put 5g of Mg-8Zn-0.5Ca medical degradable implant alloy into a quartz tube with a diameter of 15mm and a nozzle width of 0.6mm, and the equipment is vacuumed to 5.0×10 -3 Pa back filled with argon gas of 20kPa and heated by high-frequency induction heating device. When the alloy is melted and superheated at about 50°C, use 5kPa argon to spray the molten liquid onto the surface of the high-speed running copper roll. The copper roll speed is 3000rpm, and the diameter of the copper roll is 220mm. The liquid alloy is rapidly cooled on the surface of the copper roll, and along the direction of rotation of the copper roll Throw it out to form a thin strip with a thickness of 70 μm and a width of 5 mm, such as figure 2 In the Mg-8Zn-0.5Ca ribbon shown, if the cooling rate is greater than 10 6 K / s can significantly increase the strength and increase the toughness by 3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com