Bio-augmentation technology for fermentation process of solid-state brewing vinegar

A technology of bioaugmentation and fermentation process, applied in the field of bioengineering, can solve the problems that restrict the application of bioaugmentation technology and the problem of biological safety has not been well resolved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Extraction of total DNA of vinegar fermented grain microbial community

[0030] 1. Sample pretreatment of vinegar fermented grains

[0031] Take 2g of vinegar unstrained spirits sample, suspend it with 20mL 0.1M PBS (pH 7.0), add glass beads, vortex fully shake for 5min; centrifuge at 200×g for 5min, collect the supernatant (including bacteria), discard the precipitate; wash 3 times; 9000×g high-speed centrifugation for 5 minutes. Discard the supernatant and collect the precipitate; suspend the collected bacteria in 5 mL of 0.1M PBS (pH 7.0), centrifuge at 9000×g; wash 3 times; suspend the washed bacteria in 1 mL of PBS (pH 7.0), blow with a gun After vortex, shake evenly, transfer to 1.5mLEP tube, and freeze at -20°C for later use.

[0032] 2. Extraction of genomic DNA from vinegar fermented grains

[0033] Weigh 2g of vinegar unstrained spirits, add liquid nitrogen into a mortar and grind thoroughly, transfer to a 50mL centrifuge tube. Add 6 mL of DN...

Embodiment 2

[0035] Example 2: PCR-DGGE technology analyzes the structure of the microbial community of vinegar fermented grains

[0036] 1. PCR amplification

[0037] bacterial 16S rDNA V 3 Primer P used in PCR amplification of region 2 -P3 Can amplify 16S rDNA V 3 A fragment with a region of about 196bp corresponds to the sites from 341 to 534 of E. coli16S rDNA.

[0038] 2. DGGE analysis

[0039] bacterial 16S rDNA V 3 The PCR amplified products were detected by 1% agarose gel electrophoresis and the DNA concentration was determined with DyNA QuantTM 200 concentration instrument (Hoefer Pharmacia Biotech). Electrophoresis was performed with the Bio-Rad DCode DGGE system. DGGE electrophoresis conditions are: 8% polyacrylamide gel, DGGE adopts 30%-50% denaturing gradient (100% denaturant concentration is 7M urea, 40% formamide), and the loading amount is 200ng. Electrophoresis buffer was 1×TAE, 60°C, 200V voltage electrophoresis for 4h, SYBR Green I staining for 45min, UVP2GDS8000 ...

Embodiment 3

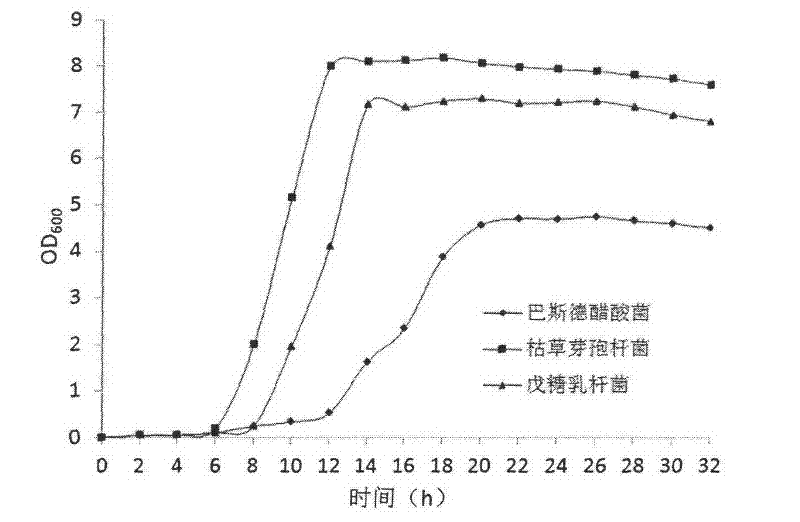

[0044] Embodiment 3: Screening of vinegar-making functional microorganisms

[0045] Take 10g sample from Zhenjiang balsamic vinegar unstrained spirits and put it into a 500mL Erlenmeyer flask mixed with glass beads and 90mL sterile water, shake it on a shaker at 37°C at 115r / m for 30min, then take 1mL of the bacterial suspension and add sterile saline 10-fold serial dilution, with 10 -2 、10 -3 and 10 -4 Spread the gradient dilution sample on GYC plate and incubate at 37°C for 48-72 hours; judge whether it is acid-producing bacteria according to whether it has a transparent circle on the GYC plate, and then pick colonies with obvious transparent circle and abundant colonies, isolate and purify them, and insert them Slant culture medium, cultured at 37°C for 48h, and stored at 4°C.

[0046] Separation medium (GYC): glucose 1%, yeast powder 1%, peptone 0.3%, light CaCO 3 0.5%, 2% agar, sterilized at 0.1Mpa at 121°C for 20min, and then added 6% absolute ethanol (v / v) after coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com