Cross-linking adsorbent resin with ultrahigh magnetic property and preparation method thereof

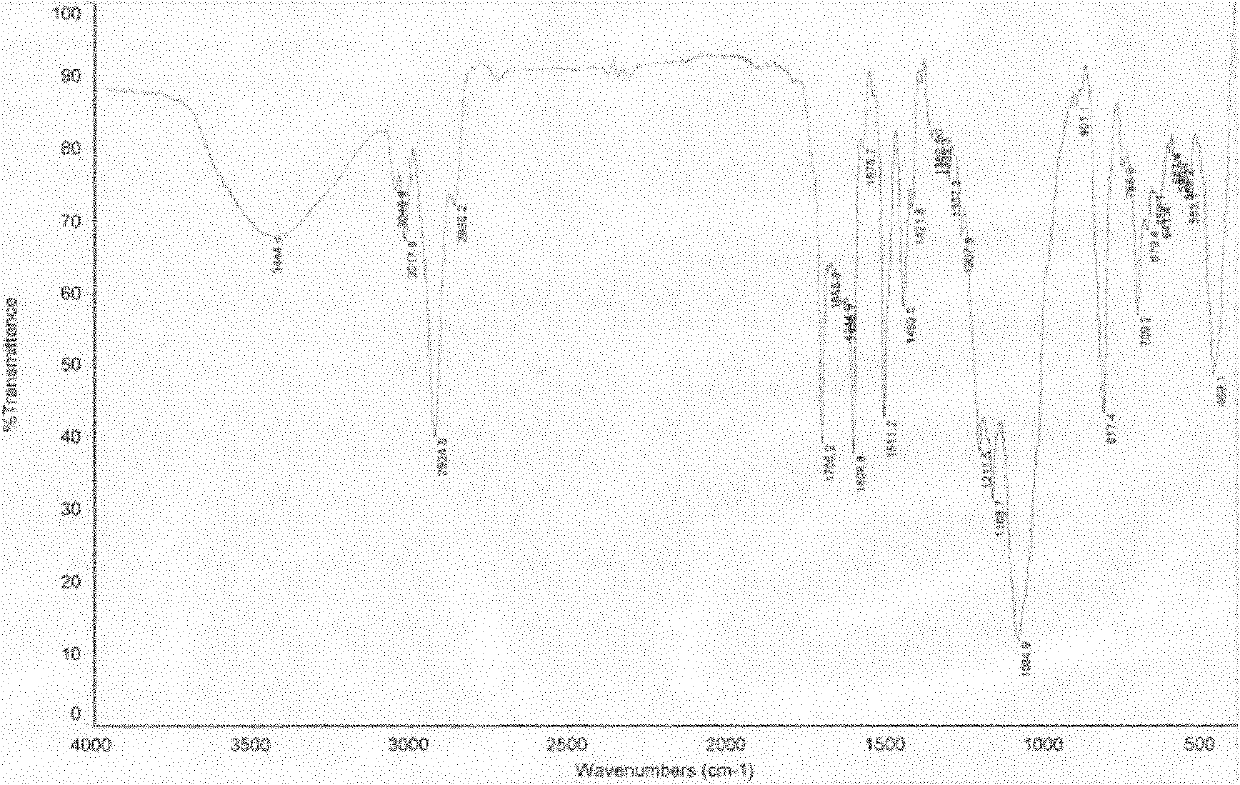

A technology of ultra-high cross-linking and adsorption resin, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of weak acid resistance of magnetic particle dispersion, achieve good adsorption, reduce processing costs, and enhance acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

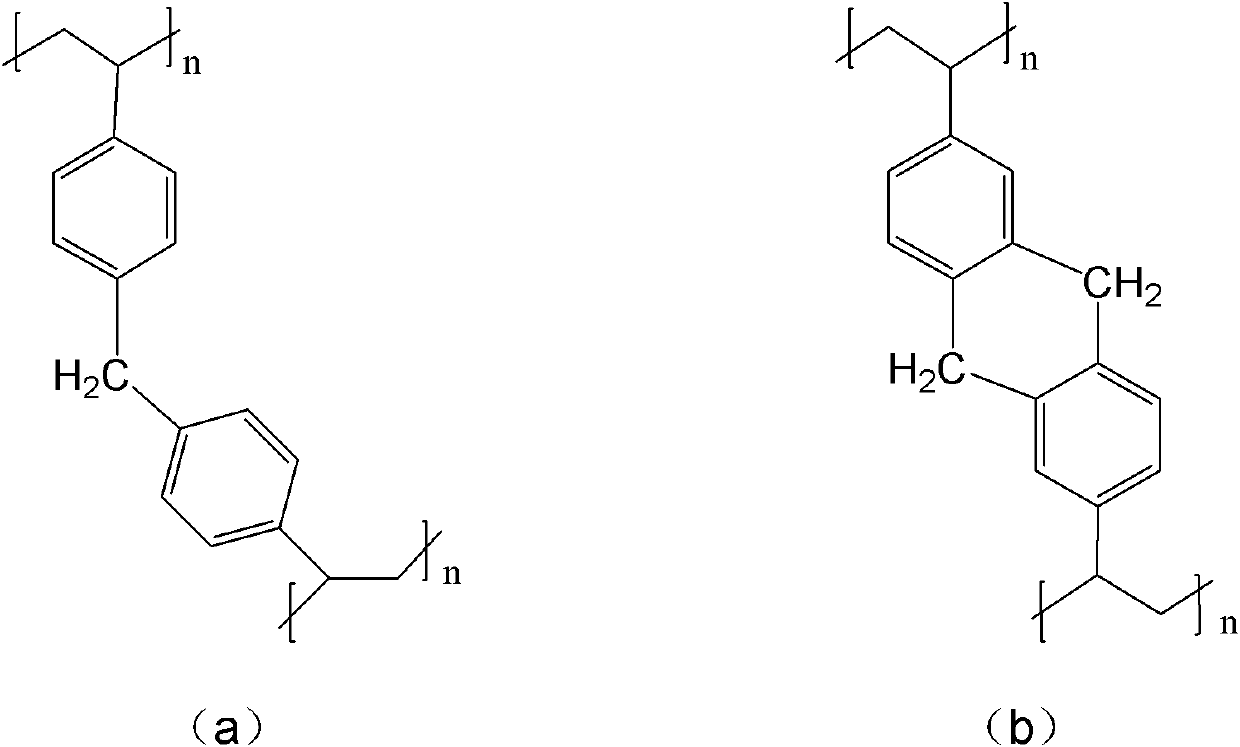

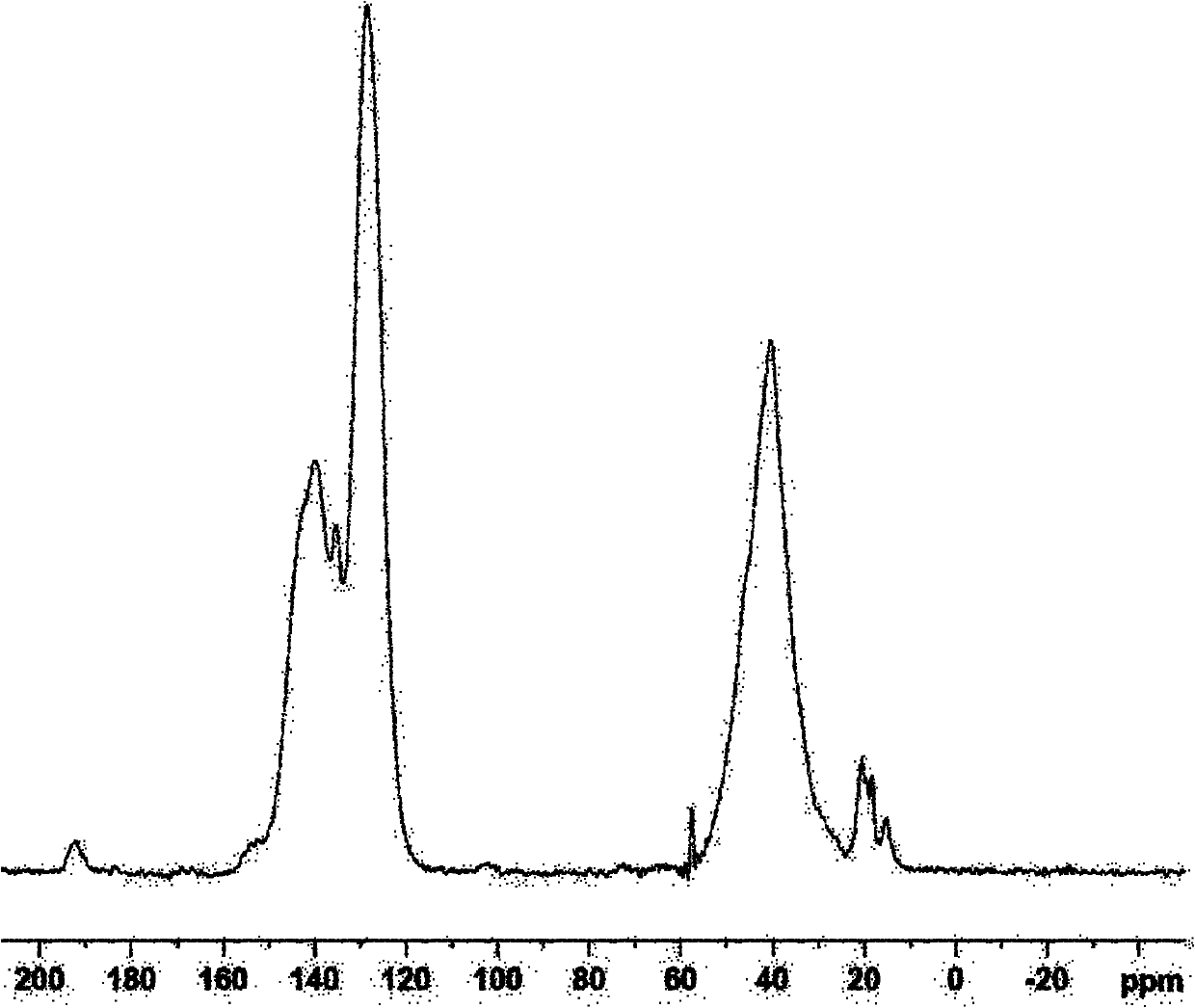

Method used

Image

Examples

Embodiment 1

[0036] Using 20g ethyl orthosilicate and 20g oleic acid to 40g γ-Fe 2 O 3 Carry out double-layer wrapping. The oil phase consisted of 60 g of chloromethyl styrene, 4 g of divinylbenzene, 17 g of n-heptane, 17 g of toluene, and 2 g of benzoyl peroxide. Dissolve 2 g of gelatin and 3 g of polyvinyl alcohol in 500 g of water to form an aqueous phase. Add the oil phase and 40 g of magnetic particles into a three-necked flask, stir quickly while adding the water phase. The temperature was raised to 70°C to initiate the reaction, polymerization was carried out for 6 hours, and the temperature was gradually raised to 95°C, and the reaction was carried out for 6 hours. Centrifuge the obtained chlorine ball, wash with water, ethanol and acetone, add dichloroethane to swell after drying, and under the condition of nitrogen protection and external lye, add 60% sodium carbonate and 80% ferric chloride of resin mass , React at 80°C for 12 hours, and wash with ethanol and acetone to obtain ...

Embodiment 2

[0039] Using 35g ethyl orthosilicate and 35g vinyl trimethoxysilane to 35g Fe 3 O 4 Carry out double-layer wrapping. The oil phase is composed of 40 g chloromethyl styrene, 8 g divinylbenzene, 25 g n-heptane, 25 g liquid paraffin, and 2 g azobisisobutyronitrile. Dissolve 10g gelatin and 3g hydroxyethyl cellulose in 500g water to form an aqueous phase. Add the oil phase and 35 g of magnetic particles into a three-necked flask, stir quickly while adding the water phase. The temperature was raised to 70°C to initiate the reaction, polymerization was carried out for 2 hours, and then the temperature was gradually raised to 95°C, and the reaction was carried out for 2 hours. Centrifuge the obtained chlorine ball, wash with water, ethanol, acetone, add dichloroethane to swell after drying, and under the condition of nitrogen protection and external lye, add 80% sodium carbonate and 50% ferric chloride of resin mass , React at 80°C for 15 hours, and wash with ethanol and acetone to ...

Embodiment 3

[0042] 3g of stainless steel powder was double-wrapped with 3g of ethyl orthosilicate and 3g of sodium dodecylbenzene sulfonate. The oil phase is composed of 50 g chloromethyl styrene, 8 g divinylbenzene, 20 g n-heptane, 20 g isobutanol, 1 g azobisisobutyronitrile, and 1 g benzoyl peroxide. Dissolve 6g gelatin and 6g hydroxyethyl cellulose in 500g water to form an aqueous phase. Add the oil phase and 3 g of magnetic particles into a three-necked flask, stir quickly, and add the water phase at the same time. The temperature was raised to 75°C to initiate the reaction, polymerization was carried out for 4 hours, and then the temperature was gradually raised to 85°C, and the reaction was carried out for 1 hour. Centrifuge the obtained chlorine ball, wash with water, ethanol and acetone, add nitrobenzene to swell after drying, and under the condition of nitrogen protection and external lye, add 60% sodium carbonate and 40% aluminum chloride of resin mass, React at 85°C for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific saturation magnetization | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com