Hetero-junction-structured crystalline silicon solar cell with intrinsic layer and preparation method thereof

A technology of solar cells and heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unstable passivation performance, achieve the effect of reducing the surface recombination rate and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

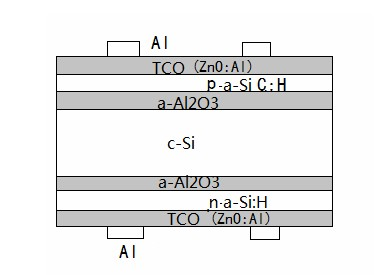

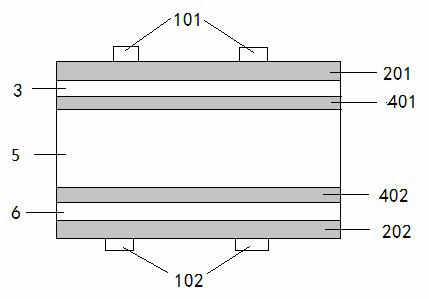

[0026] Such as figure 2 Shown, the HIT structure solar cell structure with the intrinsic layer of amorphous alumina. Its preparation process is as follows:

[0027] 1. Use the general single crystal silicon cleaning method, that is, sodium hydroxide + isopropanol (NaOH + IPA) solution to remove the surface damage of P-type CZ silicon and make texture to form an anti-reflection structure and chemical cleaning; P-type CZ silicon wafer 125 monocrystalline silicon wafers for industrial use, with a resistivity of 0.5-5 Ωcm and a thickness of 180-220um;

[0028] 2. Wash the silicon wafer obtained above with a volume ratio of HF:HCl:H2O=2:5:50 for 1 minute and then dry it, and use an atomic layer deposition (ALD) system to simultaneously prepare 5nm amorphous alumina on the upper and lower surfaces layer;

[0029] 3 Anneal the silicon wafer after depositing aluminum oxide in a nitrogen atmosphere for 15 minutes, and the annealing temperature is 425°C;

[0030] 4. Use industrial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com