Microcellular polyurethane elastomer and preparation method thereof

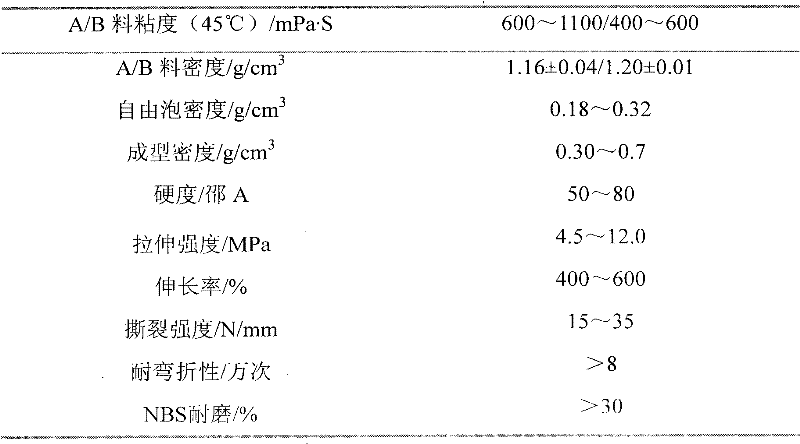

A technology of microcellular elastomer and polyurethane, applied in the field of polyurethane microcellular elastomer and its preparation, can solve the problems of high viscosity, increased viscosity of polyol components, mismatch of viscosity of two components, etc., and achieves high hardness and mechanical properties. performance, improve resilience, good flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

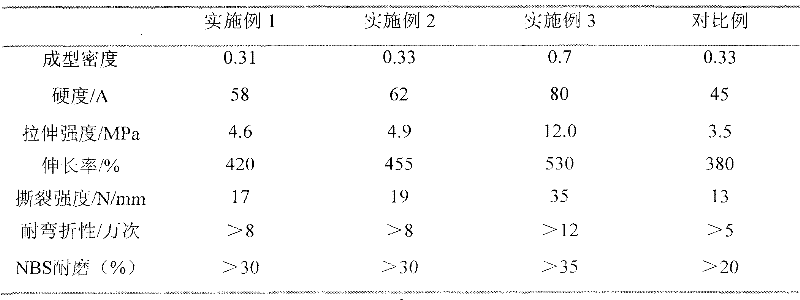

Embodiment 1

[0035] The used raw material of polyester polyol A is terephthalic acid, adipic acid, diethylene glycol and ethylene glycol, and the mol ratio of terephthalic acid and adipic acid is 1.2 / 1, and the ratio of diethylene glycol and ethylene glycol The molar ratio is 1.2 / 1, and the number average molecular weight of the obtained polyester is 1000. Polyester polyol B is a CMA-254 product of Yantai Huada Chemical Industry Company.

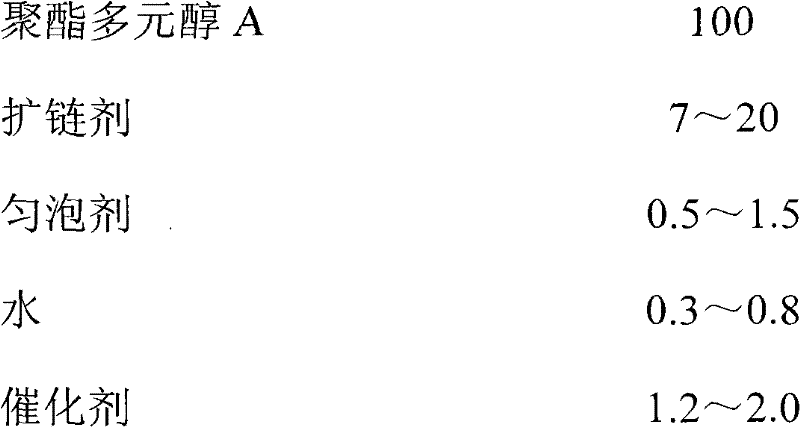

[0036] Weigh component A raw materials according to mass ratio: 100 parts of polyester polyol A, 9 parts of ethylene glycol, 0.5 parts of DC3043, 0.6 parts of water, 2.0 parts of Dabco33-LV / DabcoT-12 (mass ratio 8 / 1), Place in a reaction kettle, mix for 2 hours at 45°C, and store in a sealed container.

[0037] Weigh the raw materials of component B according to the mass ratio: 100 parts of polyester polyol B, 150 parts of MDI, react at 85°C for 1 hour, vacuumize to remove air bubbles, cool down to 50°C, take a sample and analyze that the NCO content is...

Embodiment 2

[0040] The used raw material of polyester polyol A is terephthalic acid, adipic acid, diethylene glycol and ethylene glycol, and the mol ratio of terephthalic acid and adipic acid is 0.5 / 1, and the ratio of diethylene glycol and ethylene glycol The molar ratio is 0.8 / 1, and the number average molecular weight of the polyester is 1500. Polyester polyol B is a CMA-254 product of Yantai Huada Chemical Industry Company.

[0041]Weigh component A raw materials according to mass ratio: 100 parts of polyester polyol A, 9 parts of 1,4-butanediol, 0.5 parts of DC3042, 0.6 parts of water, Dabco33-LV / DabcoT-12 (mass ratio 8 / 1) 1.2 parts, mixed at 70°C for 1 hour, sealed and stored.

[0042] Weigh the raw materials of component B according to the mass ratio: 100 parts of polyester polyol B, 120 parts of MDI, react at 60°C for 2 hours, vacuum defoam, cool down to below 50°C, take samples and analyze that the NCO content is 17%, and discharge , sealed and preserved.

[0043] Control the ...

Embodiment 3

[0045] The used raw material of polyester polyol A is terephthalic acid, adipic acid, diethylene glycol and ethylene glycol, and the molar ratio of terephthalic acid and adipic acid is 1 / 1, and the ratio of diethylene glycol and ethylene glycol The molar ratio is 0.8 / 1, and the number average molecular weight of the polyester is 2000; the polyester polyol B is a POL-2016 product of Qingdao Xinyutian Chemical Company.

[0046] Weigh component A raw materials according to mass ratio: 100 parts of polyester polyol A, 9 parts of ethylene glycol, 0.5 parts of DC193, 0.3 parts of water, 1.5 parts of Dabco33-LV / DabcoT-9 (mass ratio 8 / 1), Mix at 60°C for 1 hour, and store in a sealed container.

[0047] Weigh the raw materials of component B according to the mass ratio: 100 parts of polyester polyol B, 120 parts of MDI, 30 parts of liquefied MDI, react at 70°C for 1 hour, vacuum defoam, cool down to below 50°C, and take samples to analyze the NCO content. 20%, discharged, sealed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com