APET/PETG composite material and its production technology

A composite sheet material and production process technology, applied in other household appliances, applications, household appliances, etc., can solve the problems of high cost and high price, achieve the effects of reducing dosage, enhancing impact and tensile properties, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

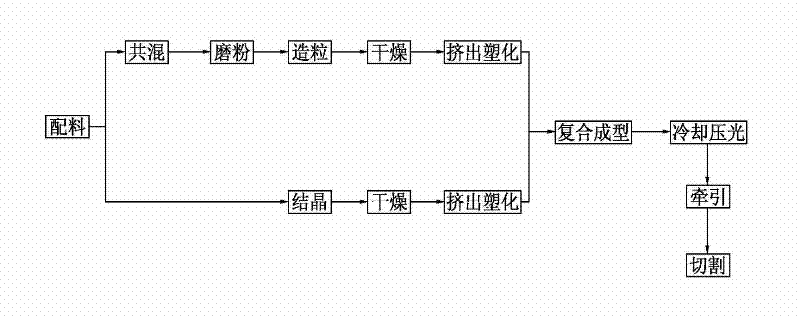

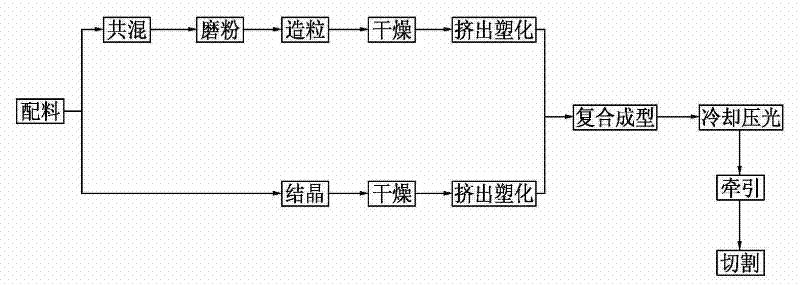

[0041] like figure 1 Shown, a kind of production technology of APET / PETG composite sheet comprises the following steps:

[0042] step one

[0043] Prepare raw materials according to the weight ratio of 80% APET slices, 15% PETG slices and 5% toughening agent; the toughening agent is composed of the following components (accounting for toughening agent weight %): ethyl terephthalate 50% glycol ester, 2% ethylene glycol isophthalate, 30% polyol acid, 17.5% polyol ester, 0.5% stearate;

[0044] step two

[0045] Unit 1 includes mixer, mill, granulator, drying cylinder 1 and extruder 1, etc. Stir and mix the toughening agent and PETG slices in the mixer evenly, and then input the blended abrasive into the mill Grinding, the ground material is sent to the granulator for granulation, and then the pellets are input into the drying cylinder for drying, and the dried material is transported to the extruder for extrusion and plasticization;

[0046] step three

[0047] Unit 2 inclu...

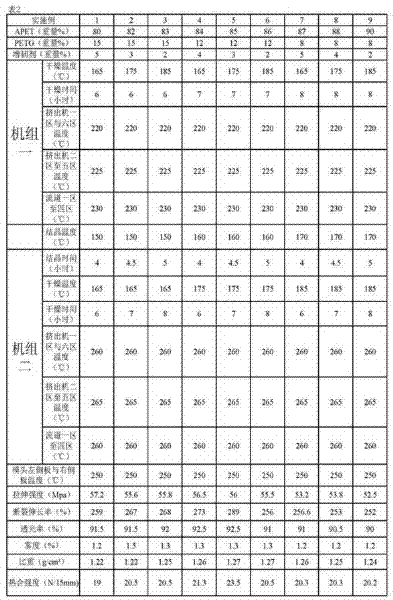

Embodiment 2

[0053] According to the weight ratio: 82% APET slices, 15% PETG slices and 3% toughening agent are prepared; the toughening agent is composed of the following components (accounting for the weight of the toughening agent): terephthalic acid 53% ethylene glycol ester, 2% ethylene glycol isophthalate, 14.5% polyol acid, 30% polyol ester, 0.5% stearate; the drying temperature in unit 1 is 175°C, and the drying time is 6 hours; the crystallization temperature in unit two is 150°C, the crystallization time is 4.5 hours, the drying temperature is 165°C, and the drying time is 7 hours.

Embodiment 3

[0055] According to the weight ratio: 83% APET slices, 15% PETG slices and 2% toughening agent are prepared as raw materials, and the toughening agent is composed of the following components (accounting for the weight of the toughening agent): terephthalic acid 55% ethylene glycol ester, 2% ethylene glycol isophthalate, 20.5% polyol acid, 22% polyol ester, 0.5% stearate; the drying temperature in unit 1 is 185°C, and the drying time is 6 hours; the crystallization temperature in unit two is 150°C, the crystallization time is 5 hours, the drying temperature is 165°C, and the drying time is 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Heat seal strength | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com