Method for preparing chemical compound type macromolecular toughening brightening additive used for plastics and product thereof

A thermoplastic polymer and polymer technology, applied in the field of polymer toughening and whitening agent and its preparation, can solve the problems of decreased mechanical properties of products, easy decrease in whiteness, exudation, etc., and achieve improved mechanical properties, whitening and brightening effects. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

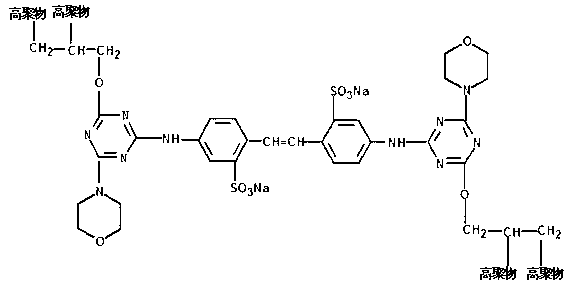

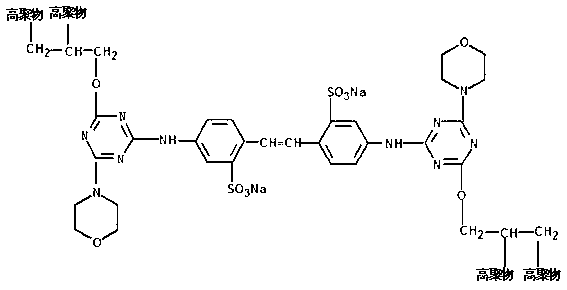

Image

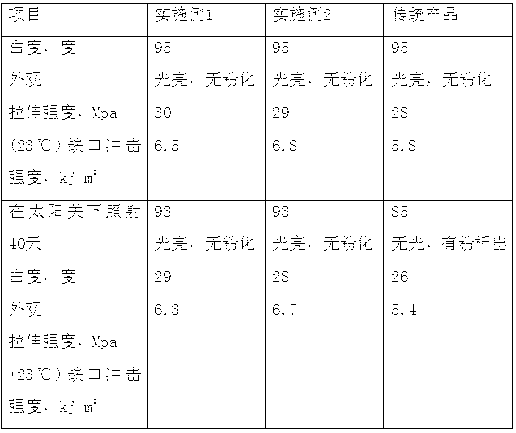

Examples

Embodiment 1

[0022] 1) Dilute 0.25 parts of vinyltriethoxysilane coupling agent with 1:1 methanol and spray it on 20 parts of titanium dioxide powder under stirring, keep it for 5-30 minutes, and control the temperature at 50 Below ℃, it becomes the inorganic whitening agent anchoring the coupling agent;

[0023] 2) Mix the titanium dioxide whitening agent of the anchoring coupling agent prepared in step 1) with 40 parts of thermoplastic elastomer SBS, 0.8 part of SBS polymer fluorescent whitening agent, 0.2 part of dicumyl peroxide, and 0.1 part of antioxidant B215 , 0.3 parts of paraffin oil lubricant, etc. are mixed in a high-speed blender, the stirring time is 5 to 10 minutes, and the temperature is below 50°C.

[0024] 3) Add the mixture prepared in step 2) into the hopper of the mixing type twin-screw extruder, and when the twin-screw extruder is heated to 150-200°C, start the feeding machine and the twin-screw extruder, and the materials enter the twin-screw extruder evenly After m...

Embodiment 2

[0026] 1) Spray 0.50 parts by mass fraction of azidotrimethoxysilane (diluted with the same mass of methanol) coupling agent on 60 parts of barium sulfate-based TiO in stirring 2 Composite white pigment, keep it for 5-30 minutes, and the temperature is below 50°C, and become an inorganic brightener anchoring the coupling agent;

[0027] 2) Combine the inorganic whitening agent of the anchoring coupling agent prepared in step 1) with 40 parts of thermoplastic elastomer EPDM, 3 parts of EPDM polymer fluorescent whitening agent, 0.5 parts of di-tert-butyl peroxide initiator, 0.2 parts Antioxidant B215 and 0.8 parts of polyethylene wax are mixed in a high-speed blender, the mixing time is 5 to 15 minutes, the speed is 400 rpm, and the temperature does not exceed 50°C.

[0028] 3) Put the mixture prepared in step 2) into the hopper of the mixing type twin-screw extruder, preheat the twin-screw extruder to 150-200°C, start the feeder and twin-screw machine, and the material is unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com