Polymer matrix composite material and production method of polymer matrix composite material

A technology of polymer materials and composite materials, applied in the field of polymer-based composite materials, can solve the problems of difficult preparation of electronic insulation packaging materials, etc., and achieve the effects of easy control of operating parameters, low dielectric loss, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

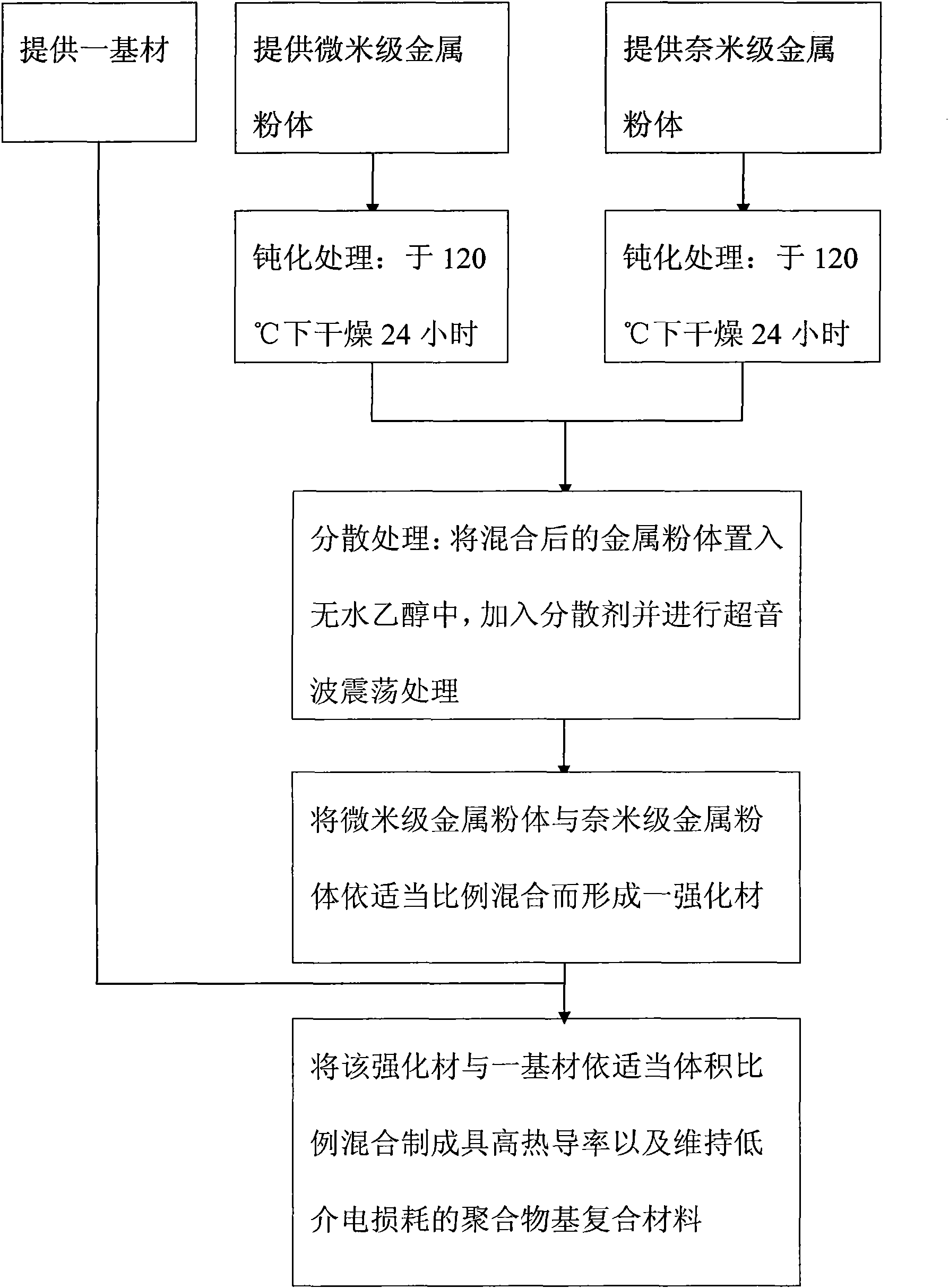

[0046] see figure 1 Shown, the preparation method of polymer-based composite material of the present invention comprises the following steps:

[0047] A metal is provided; the metal can be aluminum, chromium, nickel, iron, molybdenum, cobalt, tungsten, tantalum, niobium or other alternative metal materials.

[0048] The metal is crushed into micron-scale metal powder and nano-scale metal powder; the particle size of the micron-scale metal powder is 1 micron to 20 microns; the particle size of the nano-scale metal powder is about 10 nm to 100 nm Nano.

[0049] Passivation treatment is carried out on micron-scale metal powder and nano-scale metal powder, so that both micron-scale and nano-scale metal powder are in a passivated state; the passivation treatment is based on the surface of these metal powders Forming an oxide layer can be achieved by air heating oxidation, strong oxidant oxidation or other alternative methods; wherein the air heating oxidation method is to place t...

Embodiment 1

[0055] Embodiment 1 The present invention utilizes aluminum metal to prepare the method for reinforcing material

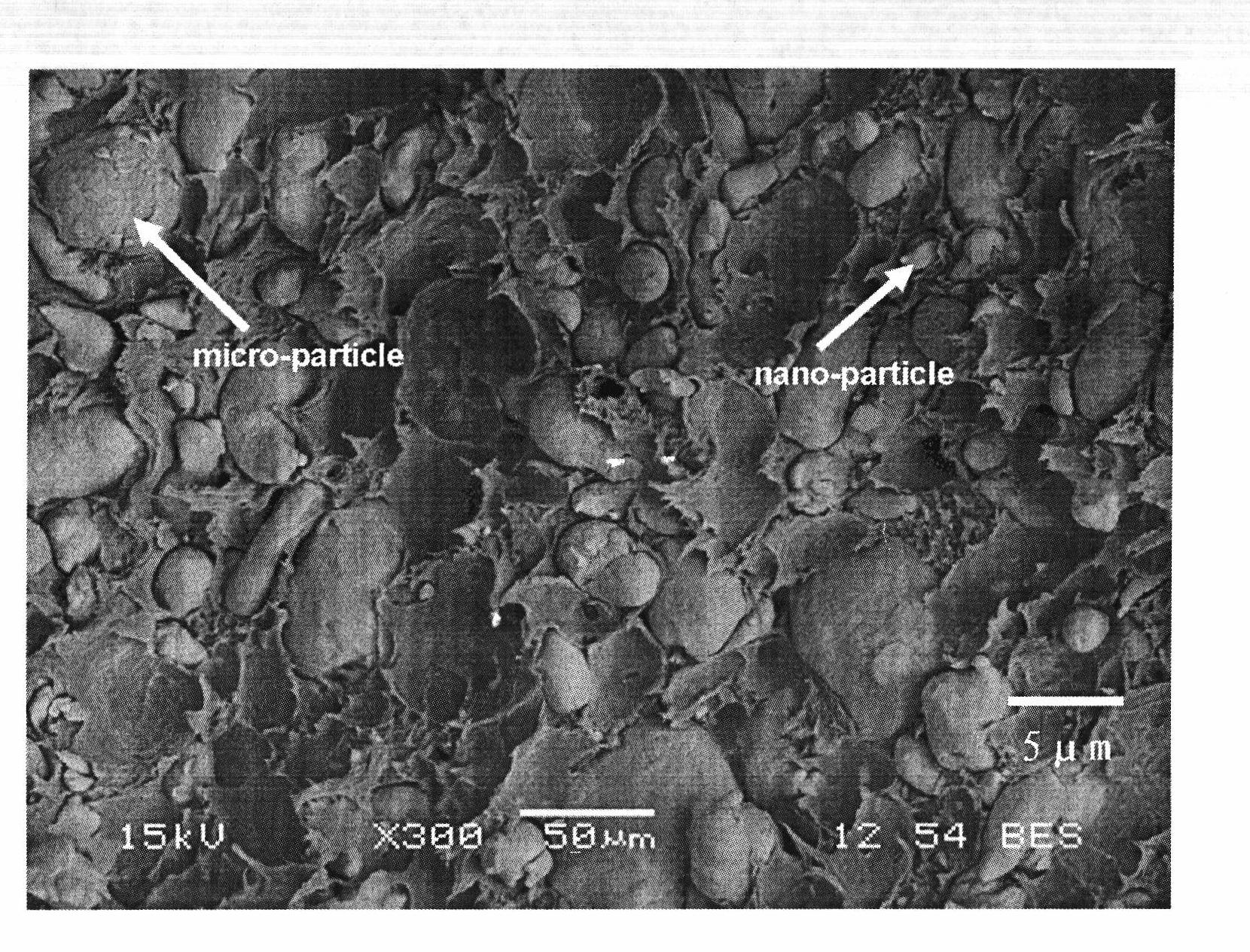

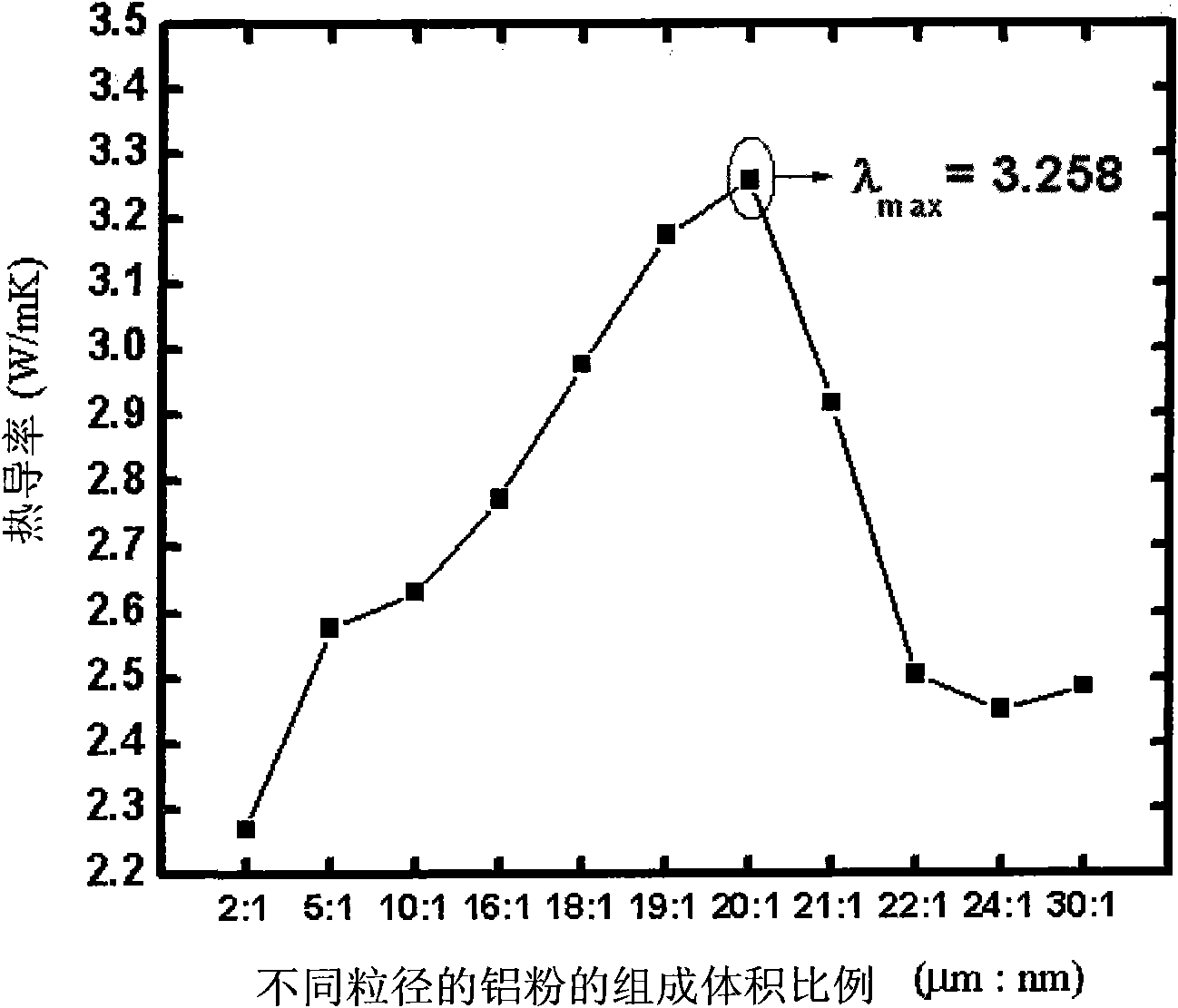

[0056] The process steps of preparing the reinforcement in this embodiment are mainly to use aluminum metal powders with different particle sizes, passivation treatment and chemical dispersion treatment, and then mix them in an appropriate proportion to form the aluminum reinforcement.

[0057] 1. Provide an aluminum metal material, which is determined to be pure aluminum without any impurities by X-ray diffraction (XRD) test; the aluminum metal material is pulverized into micron-sized aluminum powder with a particle size of about 5 microns body and nano-scale aluminum powder with a particle size of about 50 nanometers.

[0058] 2. Take 10g of pulverized micron-sized aluminum powder for passivation treatment; the passivation treatment is to dry in an aerobic environment at 120°C for 24 hours to form an oxide layer on the surface of the micron-sized aluminum powder...

Embodiment 2

[0062] Embodiment 2 The present invention utilizes the method for preparing reinforcing material of aluminum metal

[0063] The process steps of preparing the reinforcement in this embodiment are mainly to use aluminum metal powders with different particle sizes, passivation treatment and chemical dispersion treatment, and then mix them in an appropriate proportion to form the aluminum reinforcement.

[0064] 1. Provide an aluminum metal material, which is determined to be pure aluminum without any impurities by X-ray diffraction (XRD) test; the aluminum metal material is pulverized into micron-sized aluminum powder with a particle size of about 1 micron body and nano-scale aluminum powder with a particle size of about 10 nanometers.

[0065] 2. Take 10g of pulverized micron-sized aluminum powder for passivation treatment; the passivation treatment is to dry in an aerobic environment at 120°C for 24 hours to form an oxide layer on the surface of the micron-sized aluminum powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com