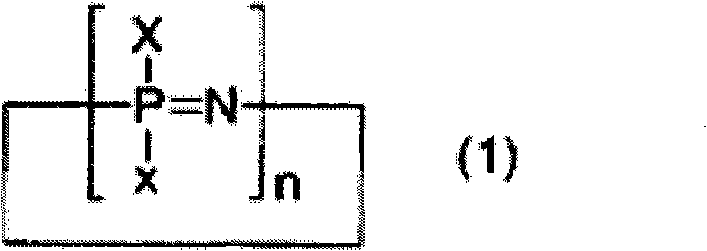

Polyamide resin, resin composition thereof, flame-retardant adhesive composition and adhesive sheet made of said composition, coverlay film, and printed wiring board

A technology of polyamide-imide resin and polyamide-imide, applied in the direction of polyurea/polyurethane adhesive, film/sheet adhesive, adhesive type, etc., can solve difficult flame retardancy Compatible with various characteristics, can not meet the problems of flame retardancy, heat resistance, soldering heat resistance, etc., and achieve the effect of excellent electrical insulation, improved adhesion, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0194] · Example 1 (polyamideimide resin 1)

[0195] Add 105.67g (0.55mol) of trimellitic anhydride, 80.09g (0.40mol) of sebacic acid, 175g (0.05mol) of carboxylic acid at both ends to a 4-necked detachable flask equipped with a stirrer, a cooling tube, a nitrogen inlet tube and a thermometer. Nitrile rubber (CTBN1300×13, number average molecular weight 3500, acrylonitrile part ratio 26wt%), 252.75g (1.0mol) 4,4'-diphenylmethane diisocyanate, 526g dimethylacetamide, under nitrogen flow The temperature was raised to 100°C, and the reaction was carried out for 2 hours. Then, add 117g of dimethylacetamide, further react at 150°C for 5 hours, add 439g of toluene and 146g of dimethylacetamide to dilute, cool to room temperature, and obtain brown polyamideimide without turbidity at all Resin solution 1.

[0196] The inherent viscosity, glass transition temperature, and tensile modulus of the polymer obtained from the resin solution were measured, and the results are shown in Table...

Embodiment 2

[0198] · Example 2 (polyamideimide resin 2)

[0199] Add 142.18g (0.74mol) of trimellitic anhydride, 40.45g (0.20mol) of sebacic acid, 210.0g (0.06mol) of Carboxylic acid nitrile rubber (CTBN1300×13), 125.13g (0.5mol) 4,4'-diphenylmethane diisocyanate, 87.08g (0.5mol) toluene diisocyanate, 517g dimethylacetamide, under nitrogen flow The temperature was raised to 100°C, and the reaction was carried out for 2 hours. Next, after reacting at 150° C. for 5 hours, 431 g of toluene and 258 g of dimethylacetamide were added for dilution, and cooled to room temperature to obtain a brown polyamideimide resin solution 2 without turbidity.

[0200] The same measurement and evaluation as in Example 1 were carried out, and the results are shown in Table 1.

Embodiment 3

[0201] · Example 3 (polyamideimide resin 3)

[0202] Add 105.67g (0.55mol) trimellitic anhydride, 92.12g (0.4mol) dodecanedioic acid, 175g (0.05mol) two-terminal Carboxylic acid nitrile rubber (CTBN1300×13), 250.25g (1.0mol) of 4,4'-diphenylmethane diisocyanate, and 535g of dimethylacetamide were heated to 100°C under a nitrogen stream, and reacted for 2 hours. Then, after reacting at 150° C. for 5 hours, 594 g of toluene and 119 g of dimethylacetamide were added for dilution, and cooled to room temperature to obtain a brown polyamideimide resin solution 3 without turbidity.

[0203] The same measurement and evaluation as in Example 1 were carried out, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com