Method for preparing squalene based on tobacco as raw material

A technology of squalene and tobacco, applied in the chemical field, achieves the effect of convenient operation, high promotion value, and prolonging the industrial chain of the tobacco industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After the tobacco waste in the cigarette production workshop is dried, it is pulverized with a pulverizer and passed through a 60-mesh sieve, and the unsifted tobacco leaves are pulverized by the pulverizer until all of them pass through the 60-mesh sieve.

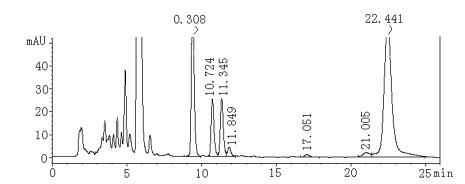

[0035] Take 100g of tobacco waste dry powder passed through a 60-mesh sieve into a 1000mL conical flask, add 300mL of ethyl formate and 60mL of distilled water, use the cold soaking method, shake once every 1h, extract at room temperature for 8h, filter, collect the filtrate, and filter the residue again Add 300 mL of ethyl formate and 60 mL of distilled water to extract again, repeat this 3 times, combine the 3 extraction filtrates, separate the layers of the filtrate with a separatory funnel, collect the ethyl formate layer, and distill off the solvent under reduced pressure to obtain squalene-containing The crude extract 3.7g, after testing the squalene content is 45%.

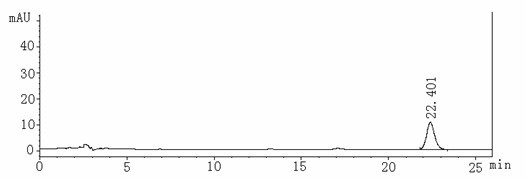

[0036] Take 1g of squalene crude extract a...

Embodiment 2

[0038] Take 100g of tobacco waste dry powder passed through a 60-mesh sieve into a 1000mL conical flask, add 288mL of ethyl formate and 72mL of distilled water, use the cold soaking method, shake once every 1h, extract at room temperature for 8h, filter, collect the filtrate, and filter the residue again Add 288mL of ethyl formate and 72mL of distilled water to extract again, repeat this 3 times, combine the 3 extraction filtrates, separate the layers of the filtrate with a separatory funnel, collect the ethyl formate layer, and distill off the solvent under reduced pressure to obtain squalene-containing The crude extract is 3.3g, and the squalene content is 35% after testing.

[0039] Take 1g of squalene crude extract and add it to silica gel chromatography (22×200mm) with 20g of silica gel, elute with petroleum ether (30-60°C), collect the colorless part of the washing solution, and remove it by vacuum distillation Petroleum ether, that is, 0.35g of squalene fine product, co...

Embodiment 3

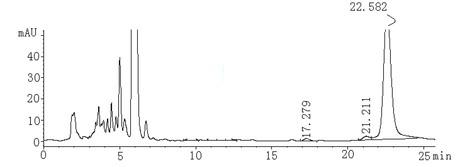

[0041] Take 100g of tobacco waste dry powder crushed through a 60-mesh sieve into a 1000mL conical flask, add 300mL of petroleum ether (60-90°C) and 50mL of distilled water, use cold soaking method, shake once every 1h, extract at room temperature for 10h, filter, Collect the filtrate, add 300mL petroleum ether (60-90℃) and 50mL distilled water to extract the filter residue again, repeat this 3 times, combine the 3 extraction filtrates, separate the layers of the filtrate with a separatory funnel, collect the petroleum ether layer, and distill under reduced pressure Remove solvent, obtain the crude extract 4.0g that contains squalene, after testing squalene content is 40.9%.

[0042] Take 1g of the crude extract and add it to silica gel chromatography (22×200mm) equipped with 20g of silica gel, elute with n-hexane, collect the colorless part of the eluate, remove n-hexane by vacuum distillation, and obtain the fine squalene 0.38g, containing 98% squalene after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com