Immobilized microbial cell method for converting ganglioside

A technology for immobilizing microorganisms and gangliosides, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as high cost of hydrolysis, difficulty in separation and purification, and short production run time, so as to improve product quality. The effect of yield and running time, stable product quality, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

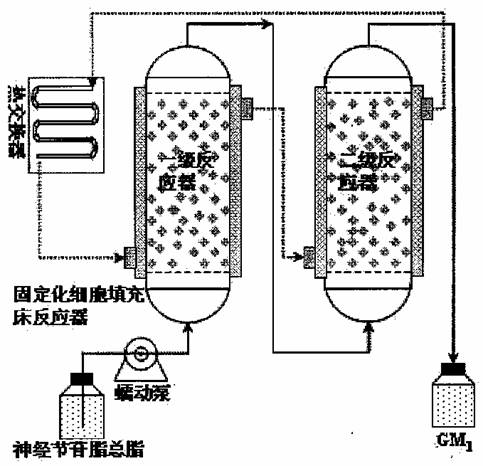

Image

Examples

Embodiment 1

[0027] (1) Cell culture

[0028] Transfer the mature Micromonas viridans cultured on the slant medium into four 1L Erlenmeyer flasks containing 250ml of seed medium (glucose 20 g / L, peptone 15 g / L, yeast powder 10 g / L, pH 7.2), culture at 28°C, 250rpm for 48 hours, and then insert 10 L of fermentation medium (polyacetylneuraminic acid 2 g / L, starch 30 g / L, ammonium sulfate 15 g / L , Potassium dihydrogen phosphate 1 g / L, magnesium sulfate 0.5 g / L, zinc sulfate 0.3 g / L) in a fermenter, stirred and aerated at 28°C for 72 hours (aeration ratio: 0.4~1.0 vvm), continuous flow The cells were collected by centrifugation, and a total of about 2000 g of wet cells were obtained. Wash twice with normal saline (0.9%) and suspend in transformation reaction buffer with a pH value of 6.1 to prepare 4 L of bacterial suspension.

[0029] (2) Preparation of porous silk fibroin gel

[0030] Weigh about 4kg of waste silk scraps, shear and pulverize them, soak them in 90°C alkaline aqueous solution...

Embodiment 2

[0036] (1) Cell culture

[0037] Transfer the mature Micromonospora viridans cultured on the slant medium into four 1L Erlenmeyer flasks containing 250ml of seed medium (glucose 20 g / L, peptone 15 g / L, yeast powder 10 g / L, pH 7.2), culture at 28°C, 250rpm for 48 hours, and then insert 10L of fermentation medium (polyacetylneuraminic acid 5 g / L, starch 30 g / L, ammonium sulfate 15 g / L, Potassium dihydrogen phosphate 1 g / L, magnesium sulfate 0.5 g / L, zinc sulfate 0.3 g / L) in a fermenter, stirred and aerated at 28°C for 36 hours (aeration ratio: 0.4~1.0 vvm), continuous flow centrifugation The cells were collected, and a total of about 1500 g of wet bacteria was obtained. Wash twice with normal saline (0.9%) and suspend in transformation reaction buffer with a pH value of 6.4 to prepare 3 L of bacterial suspension.

[0038] (2) Preparation of porous silk fibroin gel

[0039] Weigh about 4kg of waste silk scraps, shear and pulverize them, soak them in 90°C alkaline aqueous solut...

Embodiment 3

[0045] (1) Cell culture

[0046] Transfer the mature Micromonas viridans cultured on the slant medium into four 1L Erlenmeyer flasks containing 250ml of seed medium (glucose 20 g / L, peptone 15 g / L, yeast powder 10 g / L, pH 7.2), culture at 28°C, 250rpm for 48 hours, and then insert 10L of fermentation medium (polyacetylneuraminic acid 8 g / L, starch 30 g / L, ammonium sulfate 15 g / L, Potassium dihydrogen phosphate 1 g / L, magnesium sulfate 0.5 g / L, zinc sulfate 0.3 g / L) in a fermenter, stirred and aerated at 28°C for 72 hours (aeration ratio: 0.4~1.0 vvm), continuous flow centrifugation The cells were collected, and a total of about 2300 g of wet bacteria was obtained. Wash twice with normal saline (0.9%) and suspend in transformation reaction buffer with a pH value of 6.2 to prepare 4.6 L of bacterial suspension.

[0047] (2) Preparation of porous silk fibroin gel

[0048] Weigh about 4kg of waste silk scraps, shear and pulverize them, soak them in 90°C alkaline aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com