Method for adopting spray pyrolysis technology to prepare spherical anode material lithium iron phosphate

A spray thermal decomposition, lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of low volume energy density, uneven particle size distribution, low tap density, etc., to achieve volume energy density High, high tap density, stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Lithium hydroxide monohydrate (LiOH·H 2 O) 4.194 kg, ferrous oxalate (FeC 2 o 4 2H 2 O) 18.00 kg, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 11.50 kg and 0.8 kg of sucrose are placed in a ball mill, then add 67.39 kg of deionized water and carry out ball milling to make a slurry, the ball milling time is 4 hours, then carry out ultrafine grinding, the slurry particle size is controlled at 0.8 microns, and a homogeneous mixture is obtained slurry. The above-mentioned mixed slurry is atomized into fine droplets under the pressure of 5Mpa high-purity nitrogen gas, and the droplets are calcined at 300-900° C. under a nitrogen protective atmosphere to obtain lithium iron phosphate powder.

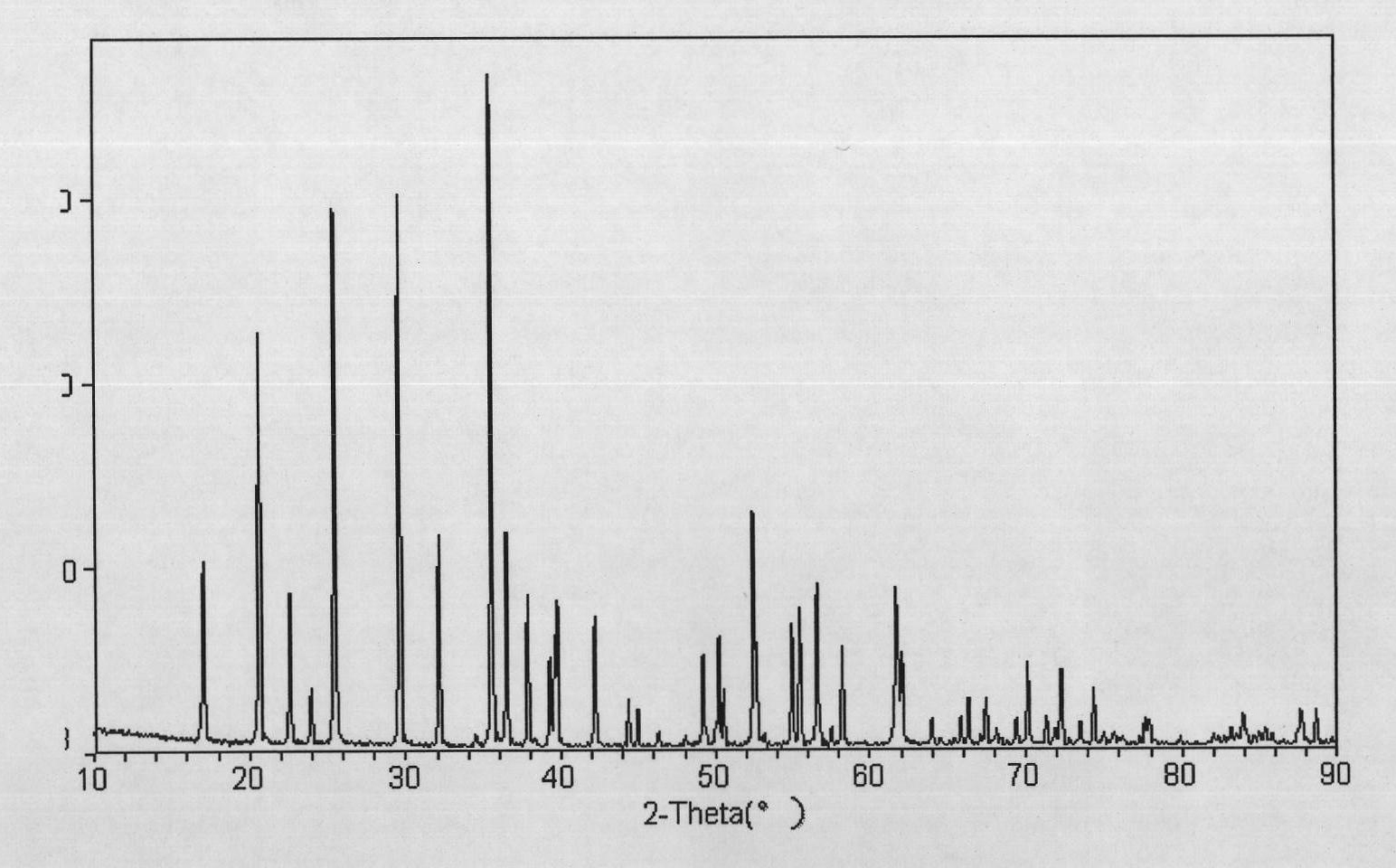

[0033] For the SEM image of the lithium iron phosphate powder prepared in Example 1, please refer to figure 1 , please refer to the XRD diagram figure 2 .

[0034] At the same time, the lithium iron phosphate powder material prepared in Example 1 is charged and discharged. T...

Embodiment 2

[0036] Lithium dihydrogen phosphate (LiH 2 PO4) 10.39 kg, ferrous oxalate (FeC 2 o 4 2H 2 O) 18.00 kg, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 11.50 kilograms and 0.8 kilograms of glucose are placed in a ball mill, then add 67.39 kilograms of deionized water and carry out ball milling to make a slurry, the ball milling time is 4 hours, then carry out ultrafine grinding, the slurry particle size is controlled at 0.8 microns, and a homogeneous mixture is obtained slurry. The above slurry is atomized into fine droplets under a pressure of 5Mpa high-purity nitrogen gas, and the droplets are calcined at 300-900°C under a nitrogen protective atmosphere to obtain lithium iron phosphate powder.

[0037] For the SEM image of the lithium iron phosphate powder prepared in Example 2, please refer to Figure 4 , please refer to the XRD diagram Figure 5 ..

[0038] At the same time, charge and discharge tests were carried out on the lithium iron phosphate powder material pr...

Embodiment 3

[0040] Lithium dihydrogen phosphate (LiH 2 PO 4 ) 10.39 kg, iron oxide (Fe 2 o 3 ) 8.00 kg and 1.0 kg of polyvinyl alcohol are placed in a ball mill. In the present embodiment, lithium dihydrogen phosphate can be used as a lithium source and a phosphorus source at the same time, then add 47.00 kg of deionized water and carry out ball milling to make slurry. The ball milling time is 4 hour, and then carry out ultra-fine grinding, the slurry particle size is controlled to 0.8 microns, and a homogeneous mixed slurry is obtained. The above slurry is atomized into fine droplets under a pressure of 5Mpa high-purity nitrogen gas, and the droplets are calcined at 300-900°C under a nitrogen protective atmosphere to obtain lithium iron phosphate powder. The tap density of lithium iron phosphate prepared in this example reaches 1.2g / cm 3 , the specific surface area is 25m2 / g, the particle size D50 is 18 microns, and the half-cell capacity is 139mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com