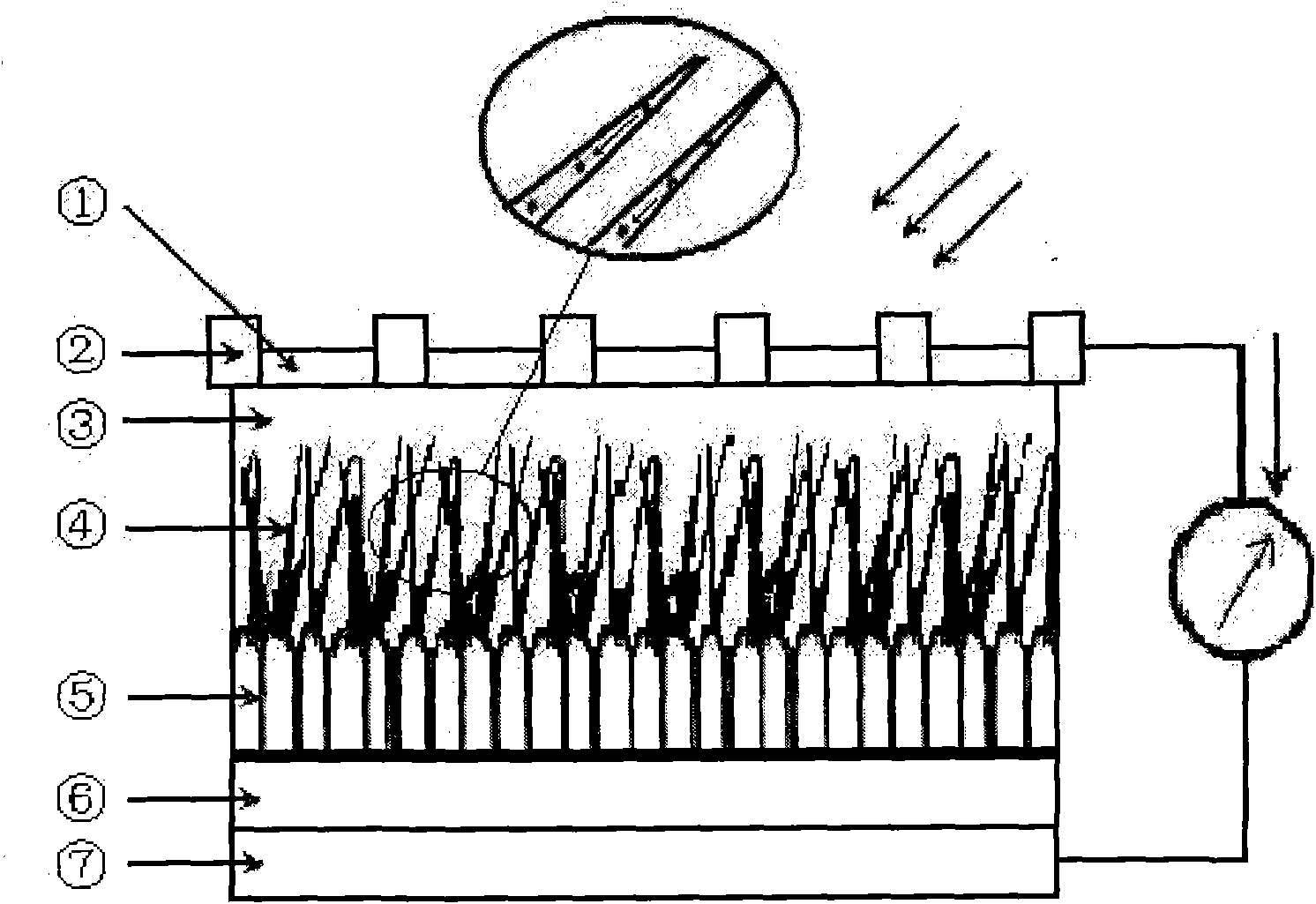

Preparation method of semiconductor nano-wire-based organic/inorganic composite solar cell

A technology of solar cells and inorganic composites, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, nanotechnology, etc., can solve the problems of reducing electron transmission rate and battery energy conversion efficiency, etc., to achieve rapid transportation, reduce crystal effect of lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The preparation method of the novel semiconductor nanowire-based organic / inorganic composite solar cell will be described in detail below.

[0023] Place n-type single crystal silicon with resistivity of 0.001-50Ω.cm in different crystal orientations (such as , , , etc.) in 0.5-7.0mol / l hydrofluoric acid and 0.01-0.50mol In the autoclave of the mixed solution of ferric nitrate, the solution volume filling degree of the autoclave is 20%-80%, and the nano-silicon substrate is prepared by hydrothermal etching at 70-170 degrees Celsius for 5-100 minutes, or Using hydrofluoric acid and ethanol solution with a volume ratio of 1:5-1:1 as the electrolytic solution, using a carbon rod as the cathode, and carrying out electrochemical corrosion with a current of 50-500mA to prepare the nano-silicon substrate. Zinc powder and oxygen are used as reaction raw materials, nitrogen is used as a protective gas, the mixing ratio of oxygen and nitrogen is 1:20-1:5, and the chemical vapor de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com