Method for preparing anti-oxidation Nb coating on surface of carbon material

A carbon material, anti-oxidation technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of affecting anti-oxidation ability, complex CVD process, and many influencing parameters, and achieve good high temperature anti-oxidation Performance, simple process, and the effect of controlling the thickness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

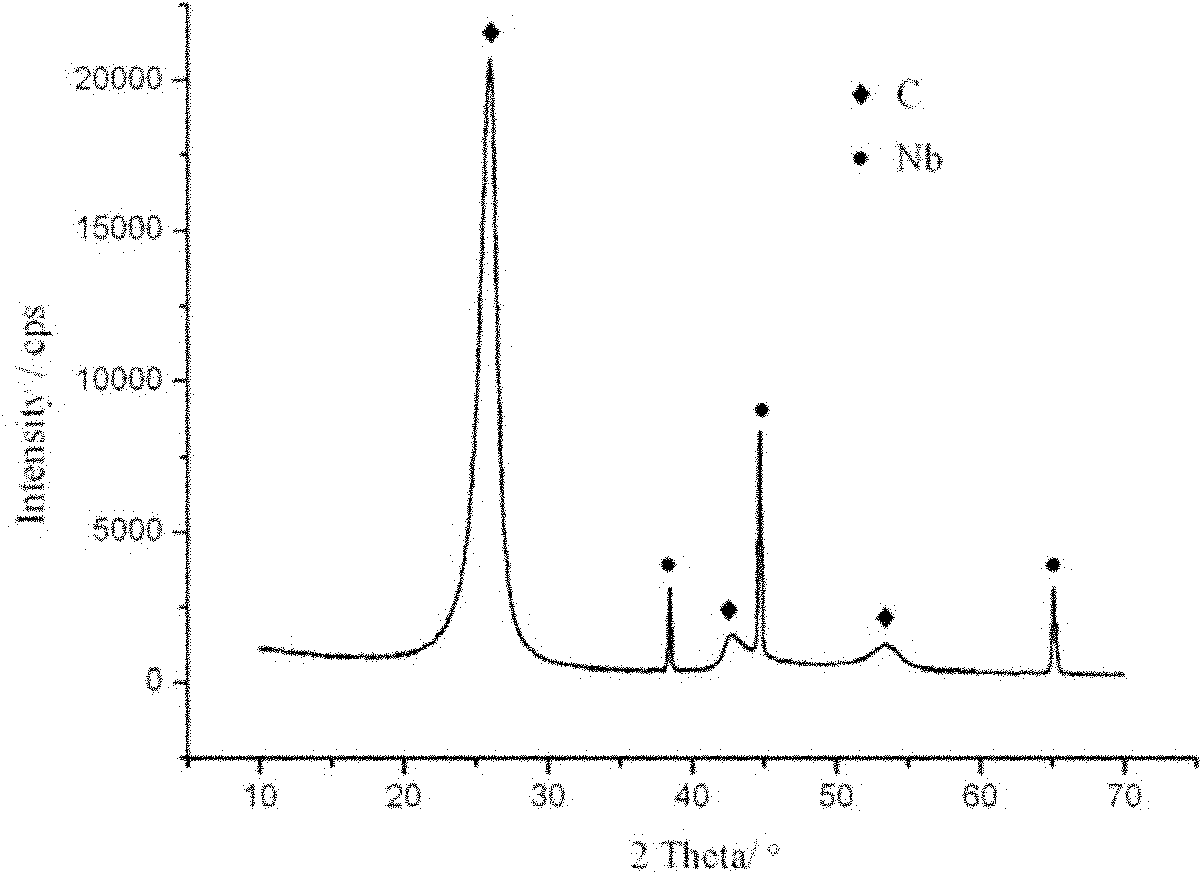

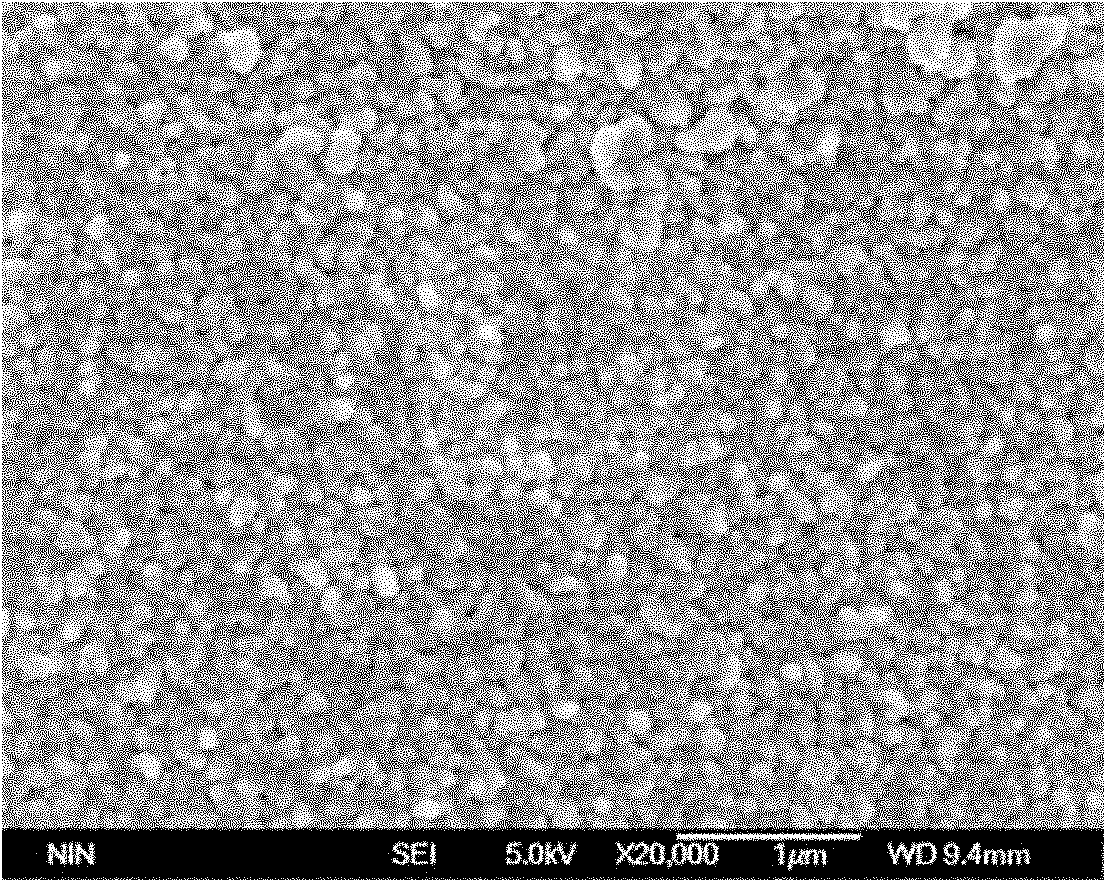

Image

Examples

Embodiment 1

[0017] Step 1: Coating carbon fiber with SiO 2 Grinding and polishing with sandpaper, then ultrasonically cleaning in absolute ethanol solution, finally rinsing with deionized water, and drying for later use;

[0018] Step 2: Using ultra-high vacuum multifunctional magnetron sputtering coating equipment, install the carbon fiber obtained in step 1 on the substrate holder in the sampling chamber;

[0019] Step 3: placing a metal Nb target with a purity of 99.9% on the DC cathode in the main sputtering chamber as a target;

[0020] Step 4: Vacuum the main sputtering chamber and sample chamber until the background vacuum is less than or equal to 10 -4 After Pa, feed the high-purity Ar gas that purity is 99.99% to it, and the pressure of argon is controlled at 3Pa;

[0021] Step 5: Adjust the distance between the carbon fiber and the target to be 30 mm, the sputtering power of the initiation is 100 W, and the sample is taken out after sputtering for 10 minutes to obtain an anti-...

Embodiment 2

[0023] Step 1: Use SiO for Graphite 2 Grinding and polishing with sandpaper, then ultrasonic cleaning in absolute ethanol solution, finally rinsing with deionized water, and drying for later use;

[0024] Step 2: Using an ultra-high vacuum multifunctional magnetron sputtering coating equipment, install the graphite obtained in step 1 on the substrate holder in the sampling chamber;

[0025] Step 3: placing a metal Nb target with a purity of 99.9% on the DC cathode in the main sputtering chamber as a target;

[0026] Step 4: Vacuum the main sputtering chamber and sample chamber until the background vacuum is less than or equal to 10 -4 After Pa, feed the high-purity Ar gas that purity is 99.99% to it, and the pressure of argon is controlled at 5Pa;

[0027] Step 5: Adjust the distance between the graphite and the target to 40 mm, the initiation sputtering power to 200 W, and take out the sample after sputtering for 20 minutes to obtain an oxidation-resistant Nb coating on the...

Embodiment 3

[0029] Step 1: SiO for carbon / carbon composites 2 Grinding and polishing with sandpaper, then ultrasonic cleaning in absolute ethanol solution, finally rinsing with deionized water, and drying for later use;

[0030] Step 2: Using an ultra-high vacuum multifunctional magnetron sputtering coating equipment, install the carbon material obtained in step 1 on the substrate holder in the sampling chamber;

[0031] Step 3: placing a metal Nb target with a purity of 99.9% on the DC cathode in the main sputtering chamber as a target;

[0032] Step 4: Vacuum the main sputtering chamber and sample chamber until the background vacuum is less than or equal to 10 -4 After Pa, feed into it the high-purity Ar gas that purity is 99.99%, and the pressure of argon is controlled at 7Pa;

[0033] Step 5: Adjust the distance between the base material and the target to 50 mm, the initiation sputtering power to 300 W, and take out the sample after sputtering for 30 minutes to obtain an oxidation-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com