Method for preparing boron nitride nanowire by cracking of polymer

A boron nitride nanometer and polymer technology, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems that BN nanowires are in the blank, and it is difficult to show the quantum size effect of nanomaterials, so as to achieve easy scale The effect of convenient production and operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Synthesize the polyalkylaminoborazine precursor with the following structural formula according to the prior art: (for synthesis see Chinese Chem. Lett. , 21, 1079 (2010), its softening point is about 75℃,

[0020]

[0021] (2) Grind the polyalkylaminoborazine precursor in a glove box under the protection of Ar gas, and sieve it with 1000 mesh; put the sieved precursor powder in a graphite boat, and in a tube furnace, In a high-purity nitrogen atmosphere, heat up to 150°C at a heating rate of 4°C / min, with a nitrogen flow rate of 60ml / min, and keep warm for 1h; then heat up to 600°C at a heating rate of 5°C / min, and keep warm for 2h; Min heating rate, control nitrogen flow rate 50ml / min, heating to 1300°C, keep warm for 2h, to obtain BN nanowires.

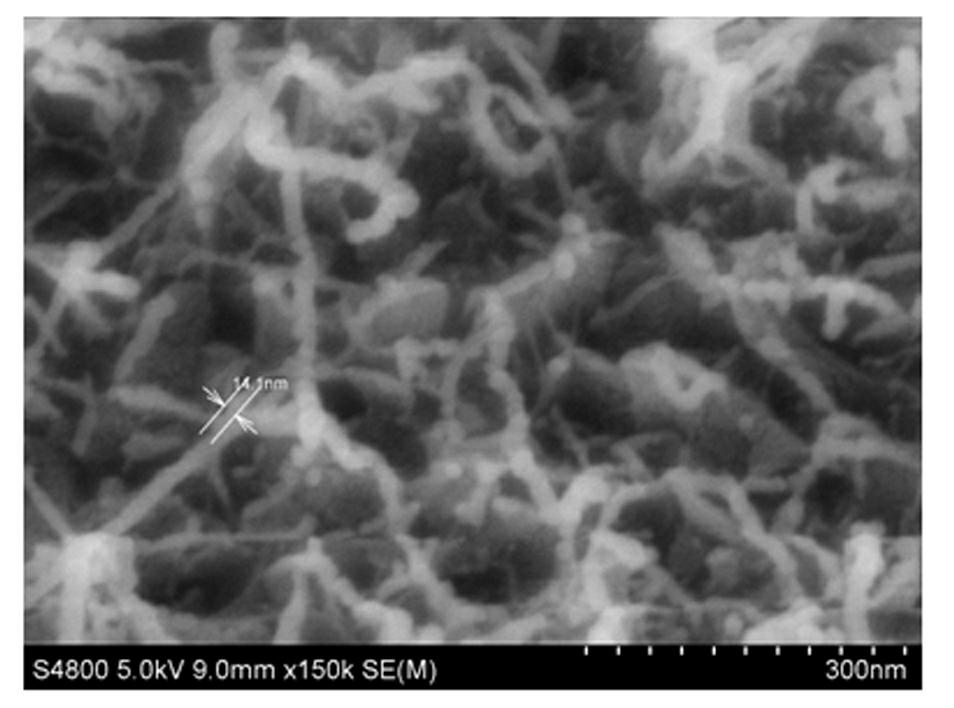

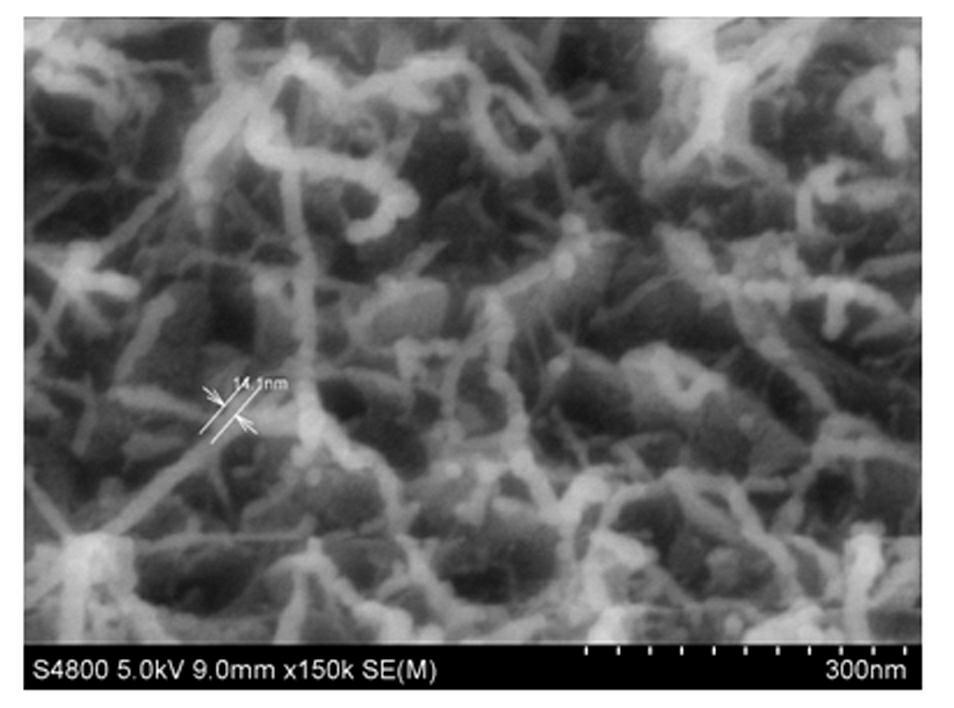

[0022] The SEM pictures of its BN nanowires are as figure 1 and figure 2 shown. Its diameter is relatively uniform, about 12~18nm.

Embodiment 2

[0024] (1) Synthesis of polyalkylaminoborazine precursor, (synthesis see Chinese Chem. Lett. , 21, 1079 (2010)), its softening point is about 83℃;

[0025] (2) Grind the polyalkylaminoborazine precursor in a glove box under the protection of Ar gas, and sieve it with 1000 mesh; put the sieved precursor powder in a graphite boat, and in a tube furnace, In a high-purity nitrogen atmosphere, the temperature was raised to 150°C at a heating rate of 4°C / min, the nitrogen flow rate was 60ml / min, and the temperature was kept for 1h; Min heating rate, control nitrogen flow rate 70ml / min, heating to 1600 ℃, keep warm for 2h, to get BN nanowires with a diameter of 12~18nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com