Large-irradiation-area atomic oxygen beam simulation system

A simulation system, atomic oxygen technology, applied in the field of simulation system, can solve the problems of inability to carry out test verification, low test efficiency, restricting the application of test technology, etc., to shorten the test period, reduce the test cost, and improve the test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

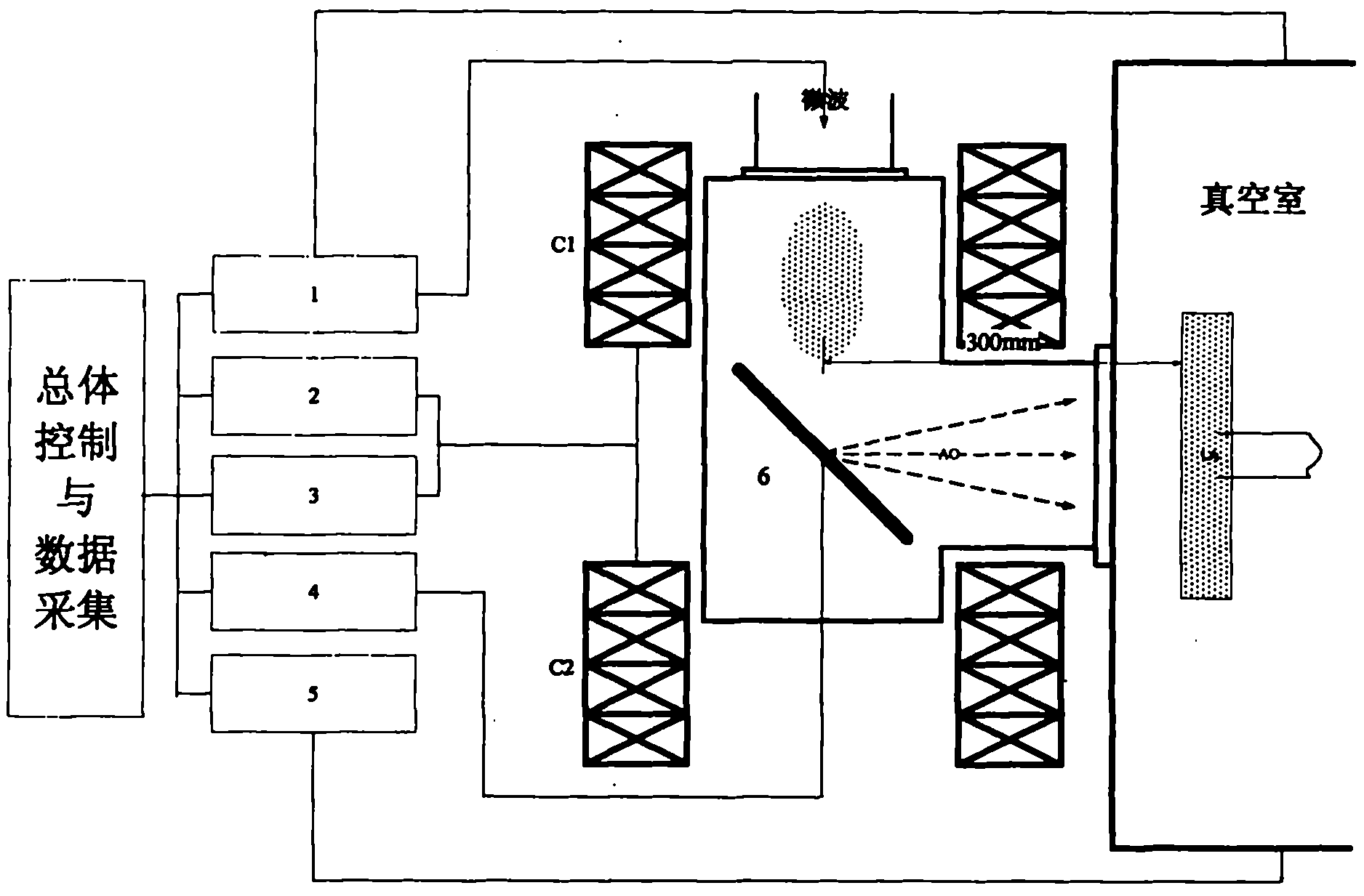

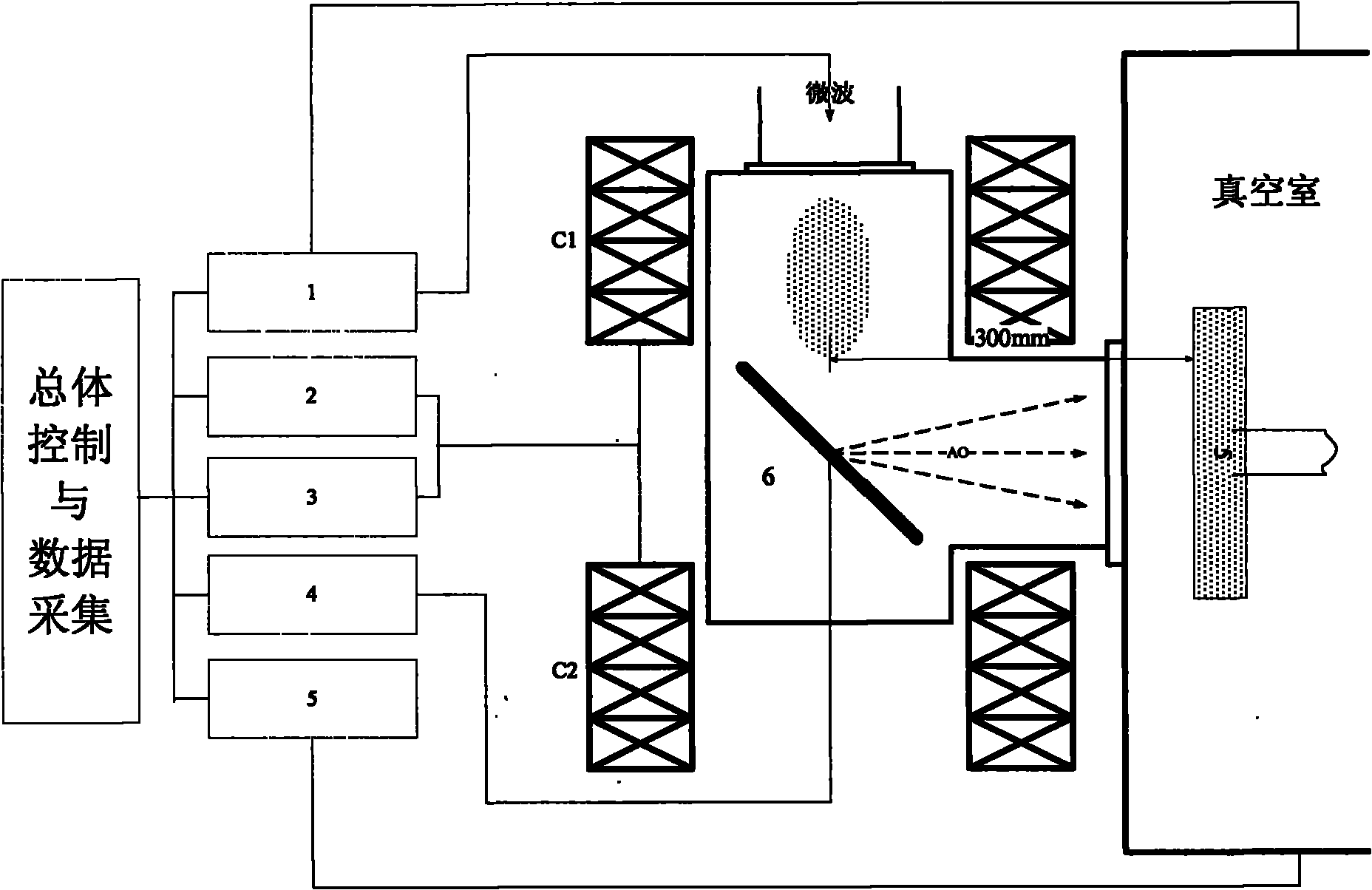

[0024] Using this large-irradiation area atomic oxygen beam simulation system, install and debug on a Φ500mm×600mm vacuum vessel to construct an atomic oxygen environment ground simulation test equipment. The atomic oxygen beam simulation system is connected with the main container through a Φ150mm flange.

[0025] According to the above methods and steps, a large irradiated area atomic oxygen beam simulation system is built. The vacuum chamber of the device is welded by non-magnetic stainless steel plates with a thickness of 4 to 5 mm, which can withstand the internal and external pressure difference caused by high vacuum and can Avoid the influence of anti-electric cavity magnetization on plasma anti-electricity. A microwave antenna window, an observation window, a molybdenum plate installation window, a molybdenum plate azimuth adjustment window, a connection window with the main container, and an electrostatic probe window are designed and processed on the container. The micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com