Azithromycin ultrafine powder in-situ gel eye drops and preparation method thereof

A technology of azithromycin and ultrafine powder, which is applied in the field of medicine, can solve the problems of prolonged residence time and low solubility of azithromycin, and achieve the effects of prolonging residence time, improving bioavailability and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

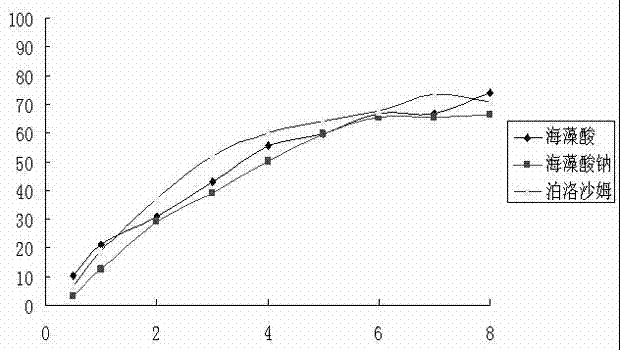

Image

Examples

Embodiment 1

[0025] Using alginic acid as the base material, (1mL deionized water for injection: 0.005g main drug)

[0026] Azithromycin superfine powder 0.5% (based on the actual content of azithromycin)

[0027] Alginic Acid 5%

[0028] NaCl 0.9%

[0029] Citric acid 0.02%

[0030] Ethylparaben 0.03%

[0031] Appropriate amount of NaOH aq to dissolve alginic acid

[0032] Add deionized water for injection to 10mL.

[0033] The specific process is:

[0034] A Polymer solution: Take 8ml of deionized water for injection, add the prescribed amount of alginic acid, and slowly add 5% NaOH solution under stirring at room temperature until it is completely dissolved. At this time, the pH of the solution should be close to 7. Then perform pressure filtration with a 0.22 μm microporous membrane.

[0035] B Preparation of ultrafine powder of azithromycin: application of chemical ultrasonic method. A certain amount of azithromycin bulk drug is dissolved in the hyd...

Embodiment 2

[0038] Using alginic acid as the base material, (1mL deionized water for injection: 0.01g main drug)

[0039] Azithromycin superfine powder 1% (based on the actual content of azithromycin)

[0040] Alginic Acid 10%

[0041] Mannitol 0.5%

[0043] Thimerosal 0.01%

[0044] Appropriate amount of NaOH aq to dissolve alginic acid

[0045] Add deionized water for injection to 10mL.

[0046] The specific process is:

[0047] A Polymer solution: Take 8ml of deionized water for injection, add the prescribed amount of alginic acid, and slowly add 5% NaOH solution under stirring at room temperature until it is completely dissolved. At this time, the pH of the solution should be close to 7. Then perform pressure filtration with a 0.22 μm microporous membrane.

[0048] B Preparation of ultrafine powder of azithromycin: application of ultrasonic emulsification solvent evaporation method. A certain amount of azithromycin is d...

Embodiment 3

[0051] Using alginic acid as the base material, (1mL deionized water for injection: 0.015g main drug)

[0052] Azithromycin superfine powder 1.5% (based on the actual content of azithromycin)

[0053] Alginic Acid 15%

[0054] KCl 1%

[0055] Sodium thiosulfate 0.08%

[0056] Benzalkonium Bromide 0.03%

[0057] Appropriate amount of NaOH aq to dissolve alginic acid

[0058] Add deionized water for injection to 10mL.

[0059] The specific process is:

[0060] A Polymer solution: Take 8ml of deionized water for injection, add the prescribed amount of alginic acid, and slowly add 5% NaOH solution under stirring at room temperature until it is completely dissolved. At this time, the pH of the solution should be close to 7. Then perform pressure filtration with a 0.22 μm microporous membrane.

[0061] B Preparation of ultrafine powder of azithromycin: application of reaction precipitation method. Accurately weigh the azithromycin raw material and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com