Temporary plugging diversion agent for refracturing of oil-water well and preparation method thereof

A technology of repeated fracturing and diverting agents, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long time to unblock, poor fluid solubility, high residue content, etc., to reduce formation blockage damage, water insoluble The effect of low substance content and avoiding the pollution of the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

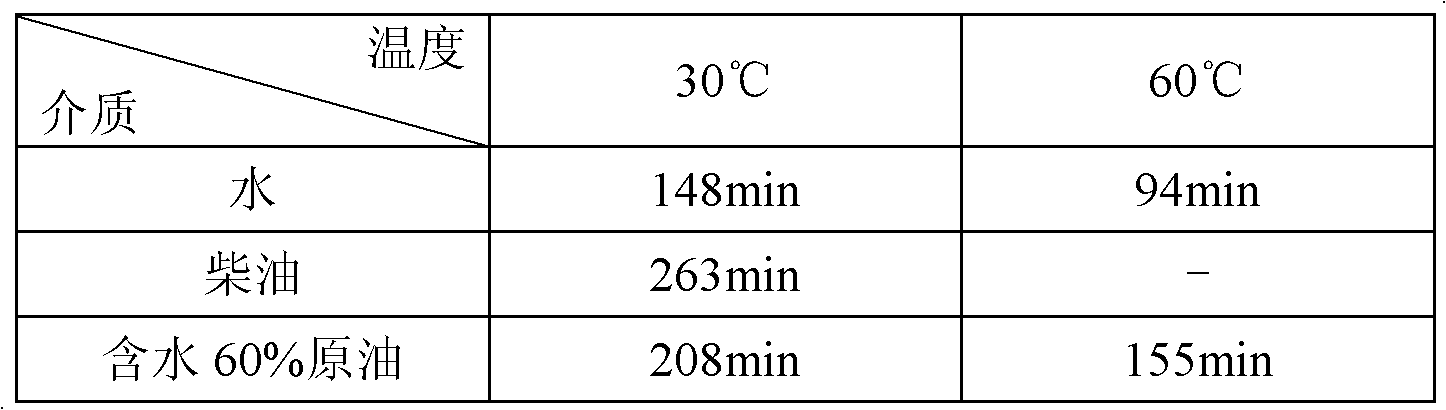

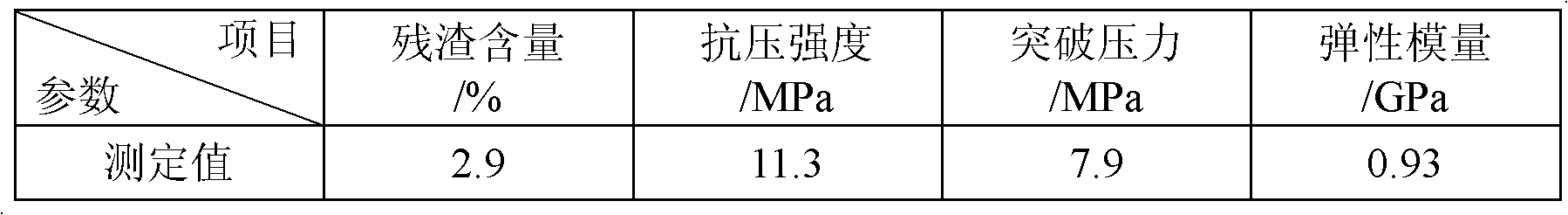

Embodiment 1

[0047] This embodiment provides a temporary plugging and diverting agent for repeated fracturing of oil and water wells, which is prepared by the following method:

[0048] (1), 3g carboxymethyl hydroxypropyl guar gum is dissolved in 100mL water and is prepared to obtain carboxymethyl hydroxypropyl guar gum aqueous solution;

[0049] (2), get 45g of bone glue and soak in the carboxymethyl hydroxypropyl guar gum aqueous solution prepared in step (1), and keep it at a constant temperature in a water bath at 30°C for 4 hours;

[0050] (3) After the bone glue swells completely, raise the temperature of the water bath to 50°C and keep it at a constant temperature for 1 hour;

[0051] (4) After the bone glue is completely dissolved, quickly add 13g of white oil and stir evenly;

[0052] (5), then, add 23g sulfonated pitch while stirring, form viscous liquid;

[0053] (6), add the carboxymethyl hydroxypropyl guar gum of 11g in viscous liquid while stirring, form viscous paste;

[...

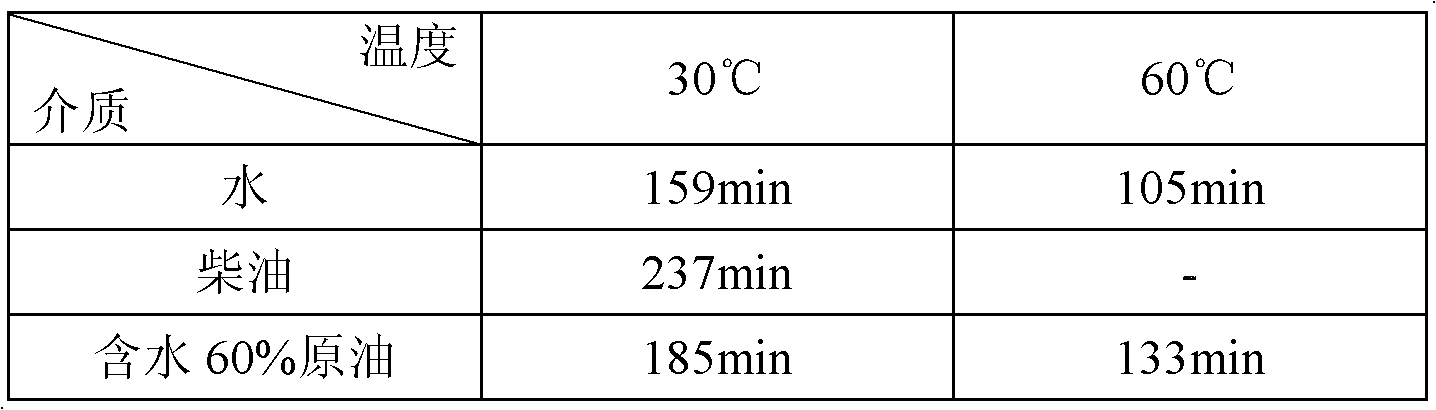

Embodiment 2

[0064] This embodiment provides a temporary plugging and diverting agent for repeated fracturing of oil and water wells, which is prepared by the following method:

[0065] (1), 3g hydroxypropyl guar gum is dissolved in 100mL water, prepares the aqueous solution of hydroxypropyl guar gum;

[0066] (2), get 40.5g of bone glue and soak in the hydroxypropyl guar gum aqueous solution prepared in step (1), and keep it in a water bath at 30°C for 4 hours at a constant temperature;

[0067] (3) When the bone glue is completely swollen, raise the temperature of the water bath to 50°C and keep it at a constant temperature for 1 hour;

[0068] (4), when the bone glue is completely dissolved, quickly add 19g of white oil and stir evenly;

[0069] (5), then, add 24g sulfonated pitch while stirring, form viscous liquid;

[0070] (6), add the hydroxypropyl guar gum of 11.5g while stirring, form viscous paste;

[0071] (7) Lay the viscous paste on a horizontal surface to form a sheet with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com