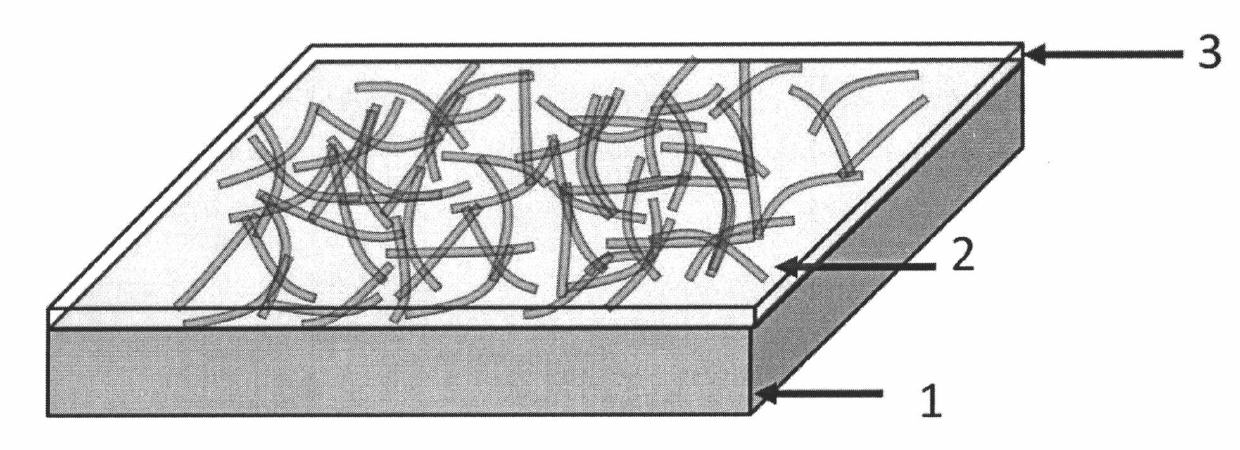

Planar silver nanowire transparent conductive thin film and preparation method thereof

A transparent conductive film, silver nanowire technology, applied in nanostructure manufacturing, conductive layer on insulating carrier, nanotechnology, etc., can solve problems such as surface is not flat enough, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

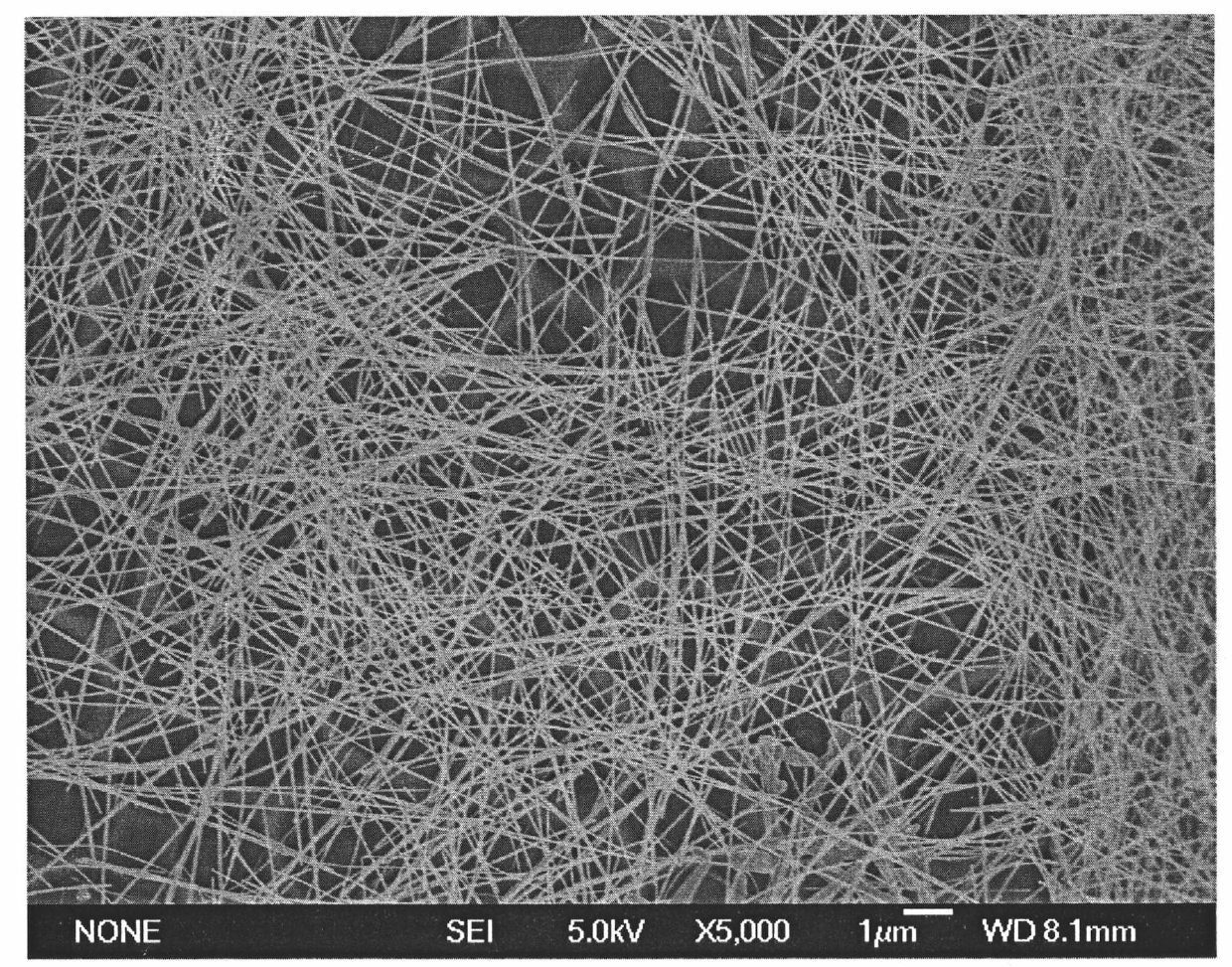

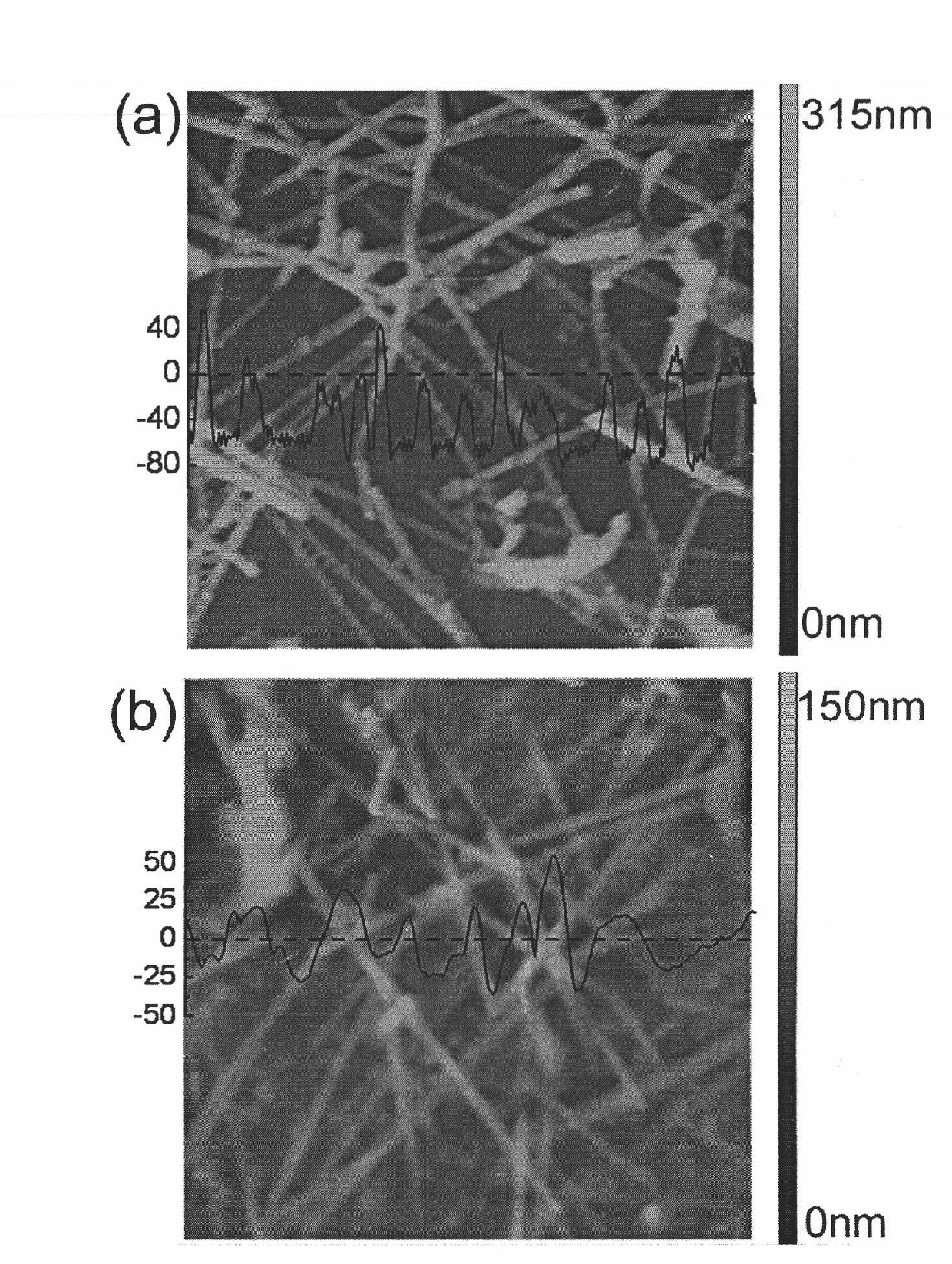

[0020] Using PET as a transparent substrate, take a specific volume of silver nanowire suspension in water and filter to form a uniform conductive network on the filter membrane. The filter film covered with the silver nanowire layer is used as a transfer film, and is pressed on the PET, and the filter film is removed after heat treatment to obtain a uniform silver nanowire conductive layer. Then the PEDOT:PSS aqueous solution was spin-coated at a speed of 1500 rpm for 15 seconds and dried at 120°C for 2 hours. The sheet resistance changes before and after spin coating PEDOT:PSS as Image 6 As shown, the visible transmittance before and after spin coating is as follows Figure 5 Shown. The 3M test after spin coating PEDOT:PSS showed that ( Figure 4 ), PEDOT:PSS coating is beneficial to improve the bonding ability of silver nanowire transparent conductive film and PET substrate.

[0021] The visible transmittance and sheet resistance of the transparent conductive film of silver...

Embodiment 2

[0023] Take ordinary float glass as a substrate, take a specific volume of silver nanowire suspension in water, filter, and form a uniform conductive network on the filter membrane. The filter film covered with the silver nanowire layer is used as a transfer film, and is pressed on the PET, and the filter film is removed after heat treatment to obtain a uniform silver nanowire conductive layer. Then the PEDOT:PSS aqueous solution was spin-coated at a speed of 1500 rpm for 15 seconds and dried at 120°C for 2 hours. The obtained transparent conductive film can pass the 3M tape adhesion test, and its visible light transmittance and square resistance are similar to those of Example 1.

[0024] The visible transmittance and sheet resistance of the transparent conductive film of silver nanowires on PET can be adjusted by the distribution density of silver nanowires. The distribution density of silver nanowires is 25mg / m 2 -318mg / m 2 . In the case of spin-coating PEDOT:PSS once, when t...

Embodiment 3

[0026] Use ordinary float glass as the substrate and use standard cleaning procedures to obtain a clean hydrophilic surface. Take a specific volume of ethanol suspension solution of silver nanowires, spin-coating at a speed of 1500 revolutions per minute for 15 seconds to form a uniform film on the glass, heat treatment for 1 hour to form a uniform silver nanowire conductive network. Then the PEDOT:PSS aqueous solution was spin-coated at a speed of 1500 rpm for 15 seconds and dried at 120°C for 2 hours. The obtained transparent conductive film can pass the 3M tape adhesion test, and its visible light transmittance is similar to that of Example 1 and Example 2, but the sheet resistance is about 40-60% higher under the same distribution density of silver nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com