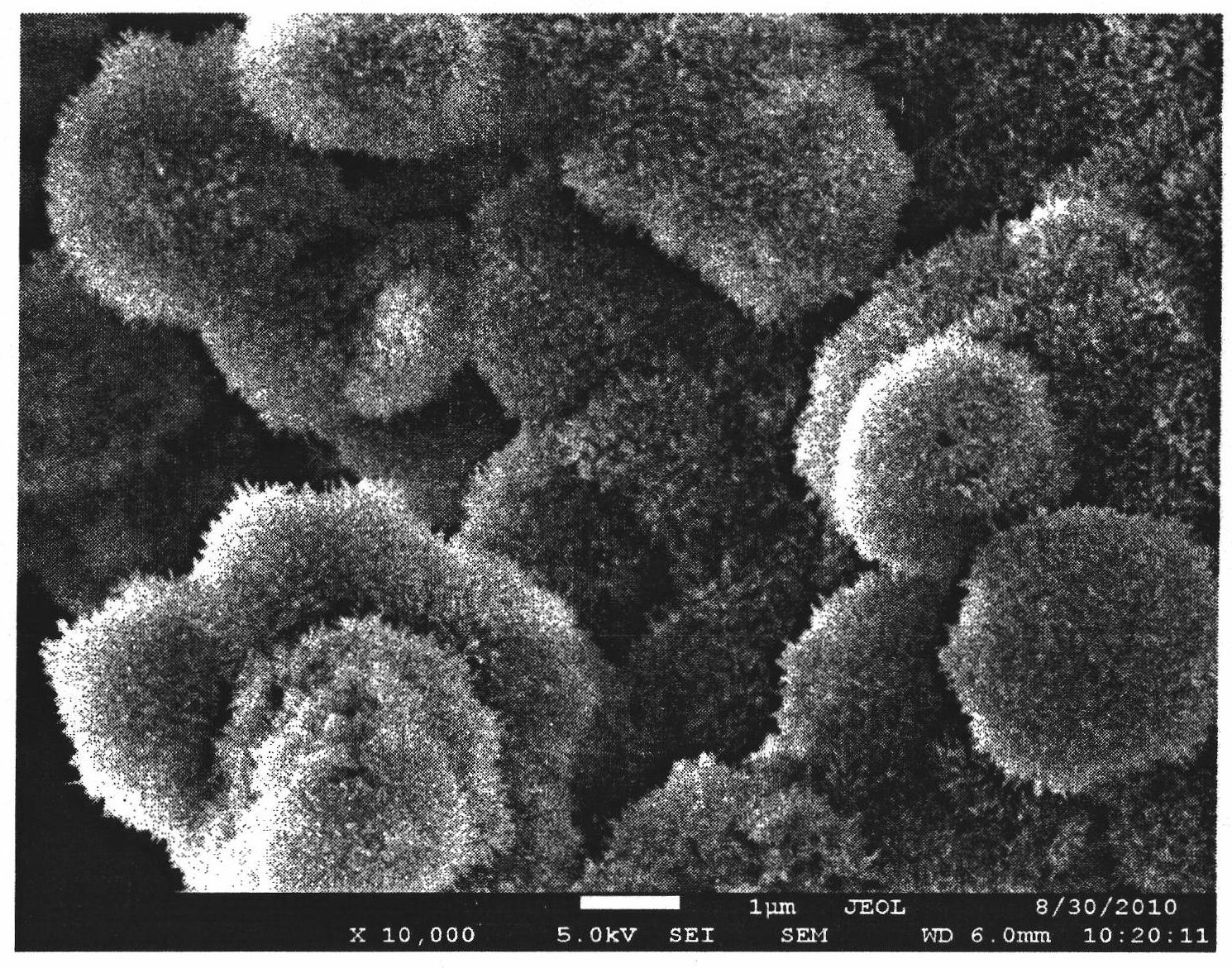

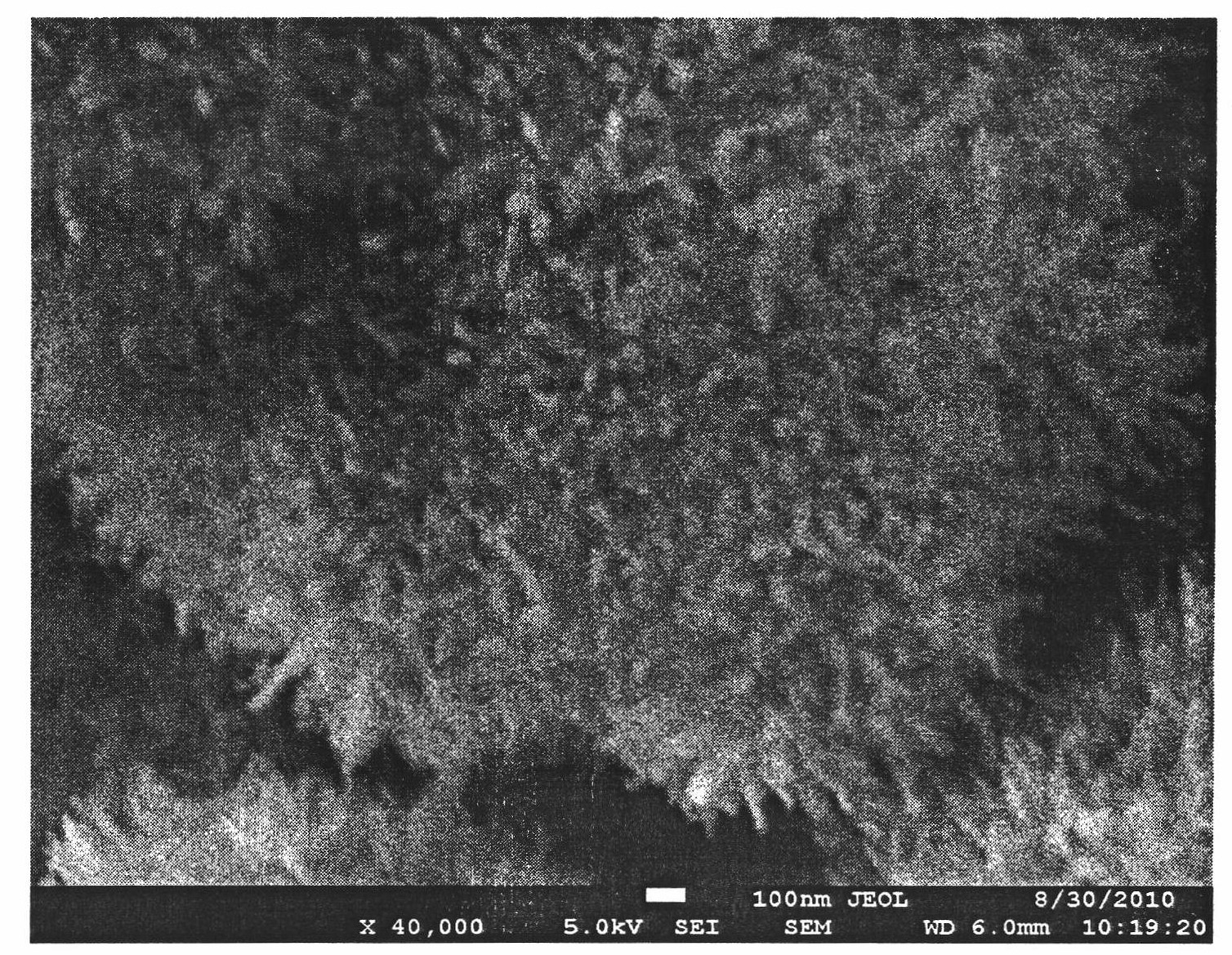

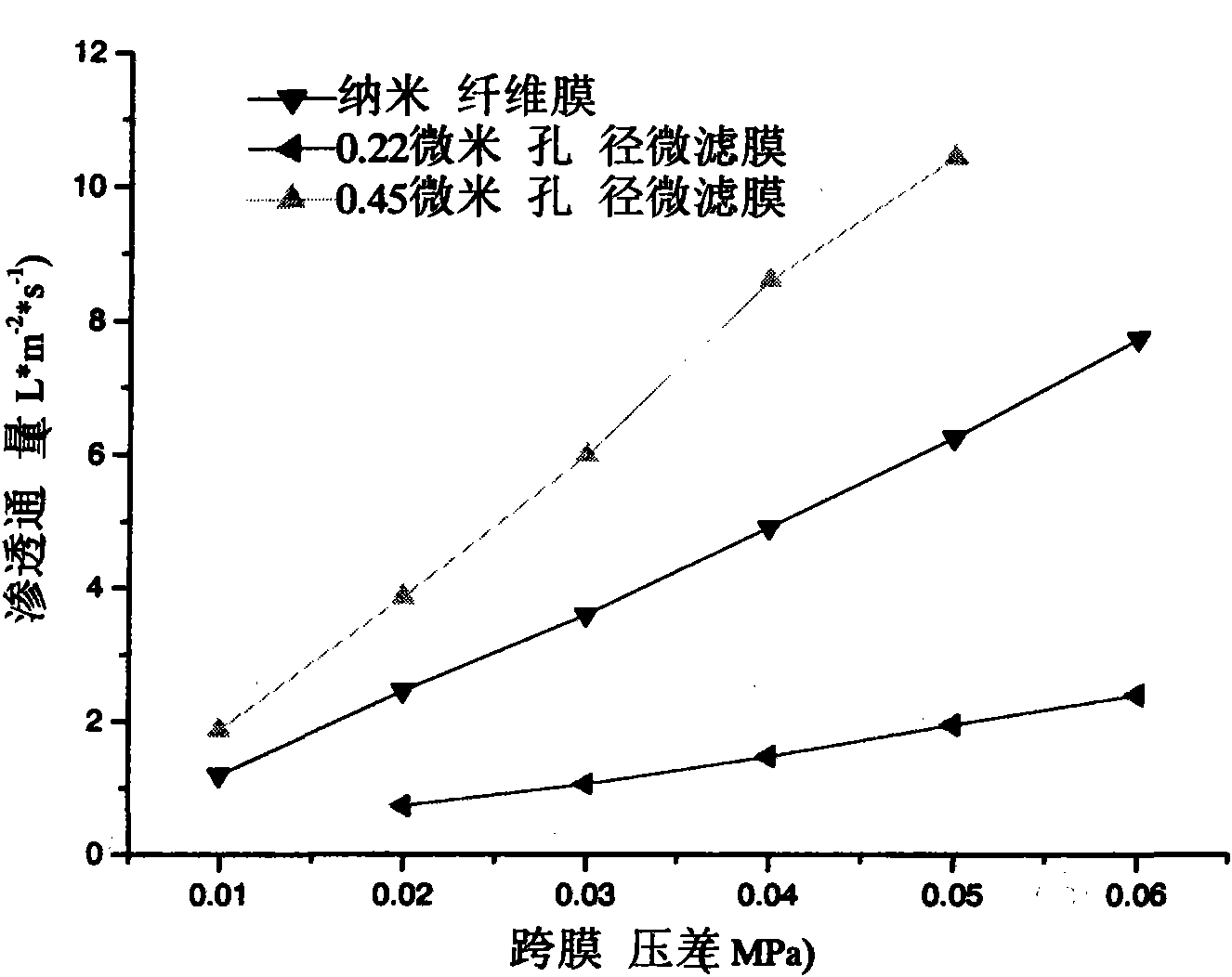

Preparation method for positively charged three-dimensional nanofibre membrane

A three-dimensional nanometer and nanofiber technology, applied in the field of fiber membranes, can solve the problems of complex process and high cost, and achieve the effects of high yield, light deformation and moderate elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 99.9% aluminum powder and analytically pure hydrochloric acid, heat the hydrochloric acid to 90°C, slowly add aluminum powder, after a violent reaction, put it in a water bath and heat it to reflux at 90°C for 8-12 hours until all the solids are dissolved to obtain an alumina sol .

[0047] Add 20% (as Al 2 o 3 Calculate) aluminum acetate formaldehyde, disperse and dissolve at 90°C, concentrate in vacuum at 60-100°C, until the viscosity rises to the level that can be spun, then filter and spin to form a film. The obtained plain silk film is dried at 50-100° C. for 12 hours, then sintered at 1000° C., and cooled with the furnace.

[0048] Put the obtained fibrous membrane skeleton into the upper layer of the autoclave, and the lower layer is a solid obtained by precipitating 2mol / L aluminum nitrate with 10% ammonia water, and prepare it into a 10% aqueous solution, pH = 5-6, heat it at 200°C for 24 hours, take it out, Wash 3 times with pure water and 2 times with...

Embodiment 2

[0050] First, prepare acidic silica sol: dissolve sodium silicate to make a solution, filter with ammonia-type resin to obtain ammonium silicate, heat and concentrate to hydrolyze ammonium silicate, release ammonia gas, and then adjust pH=2 with hydrogen-type resin ~3, you can get acidic silica sol.

[0051] The alumina sol prepared in embodiment 1 is mixed with acidic silica sol, and the ratio is (Al 2 o 3 : SiO 2 ) 3:2, add 20% (with Al 2 o 3 Calculate) aluminum acetate formaldehyde, disperse and dissolve at 90°C, concentrate in vacuum at 60-100°C, until the viscosity rises to the level that can be spun, then filter and spin to form a film. The obtained plain silk film is dried at 50-100° C. for 12 hours, then sintered at 800° C., and cooled with the furnace.

[0052] Put the obtained fiber membrane skeleton into the upper layer of the autoclave, and the lower layer is the precipitation produced by adding 2 mol / L sodium aluminate dropwise to 5 mol / L acetic acid. Take i...

Embodiment 3

[0054] The alumina sol, acidic silica sol and boric acid prepared in embodiment 1 and 2 are mixed, and add a small amount of glucose or sucrose, the ratio is (Al 2 o 3 : SiO 2 :B 2 o 3 )61.8%: 24.2%: 14%, the ratio of sugar is 2 times or 3 times that of B, adding 20% (using Al 2 o 3 Calculate) aluminum acetate formaldehyde, disperse and dissolve at 90°C, concentrate in vacuum at 60-100°C, until the viscosity rises to the level that can be spun, then filter and spin to form a film. The obtained plain silk film is dried at 50-100° C. for 12 hours, then sintered at 800° C., and cooled with the furnace.

[0055] Put the obtained fiber membrane skeleton into the upper layer of the autoclave, and the lower layer is the precipitation produced by adding 2 mol / L sodium aluminate dropwise to 5 mol / L acetic acid. Ethylene glycol, heated in water at 150°C for 48 hours, put in 0.6mol / L NaAlO 2 In the solution, add an appropriate amount of cetyl ammonium bromide, drop 10% H 2 o 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com