A kind of preparation method of conductive fiber with stretchable and low resistance change

A conductive fiber and low-resistance technology, which is applied in the manufacture of conductive/antistatic filaments, the manufacture of extensible conductors/cables, and the chemical characteristics of fibers, can solve the problems of increased resistance and the influence of electrode collection signals, etc. properties, the preparation method is simple, and the effect of maintaining stability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

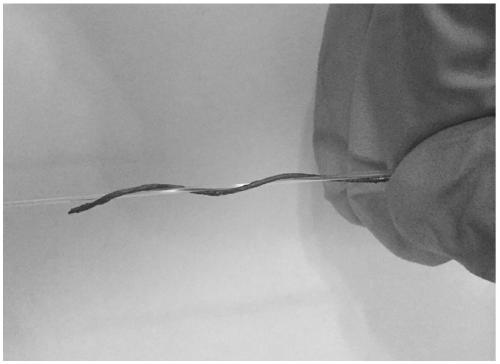

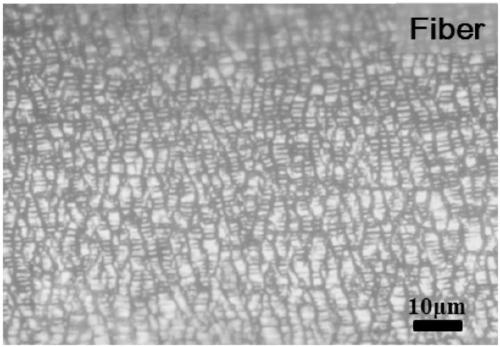

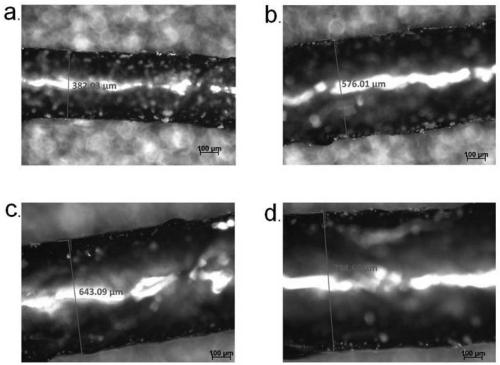

[0044] A kind of preparation method of the conductive fiber of stretchable, low resistance change comprises the following steps:

[0045] α1. Preparation of PDMS film: First, mix the PDMS monomer and cross-linking agent in a mass ratio of 10:1, stir for 5 minutes, place the evenly mixed PDMS in a vacuum desiccator to remove air bubbles, and then place it in a petri dish with a diameter of 18cm Pour an appropriate amount of deionized water into the water, drop a few drops of PDMS except for air bubbles on the surface of the deionized water, and finally place the petri dish in a 60°C oven. After 2 hours, the PDMS film can be peeled off from the water surface, and the PDMS can be added dropwise by adjusting Films of different thicknesses can be prepared. By dropping 25 μL of PDMS, the thickness of the prepared film was about 10 μm.

[0046] α2. Preparation of conductive layer: After peeling off the PDMS film from the water surface, place it in an oven at 60°C for 30 minutes to r...

Embodiment 2

[0049] A kind of preparation method of the conductive fiber of stretchable, low resistance change comprises the following steps:

[0050] β1. Preparation of PDMS film: first mix PDMS monomer and cross-linking agent in a mass ratio of 10:1, stir for 5 minutes, place the evenly mixed PDMS in a vacuum desiccator to remove air bubbles, and then place it in a petri dish with a diameter of 18cm Pour an appropriate amount of deionized water into the water, drop a few drops of PDMS except for air bubbles on the surface of the deionized water, and finally place the petri dish in a 60°C oven. After 2 hours, the PDMS film can be peeled off from the water surface, and the PDMS can be added dropwise by adjusting Films of different thicknesses can be obtained. By dropwise adding 32.5 μL of PDMS, the film thickness was about 13 μm.

[0051] β2. Preparation of conductive layer: After peeling off the PDMS film from the water surface, place it in an oven at 60°C for 30 minutes to remove the de...

Embodiment 3

[0054] A kind of preparation method of the conductive fiber of stretchable, low resistance change comprises the following steps:

[0055] γ1. Preparation of PDMS film: First, mix the PDMS monomer and cross-linking agent in a mass ratio of 10:1, stir for 5 minutes, place the evenly mixed PDMS in a vacuum desiccator to remove air bubbles, and then place it in a petri dish with a diameter of 18 cm. Pour an appropriate amount of deionized water into the water, drop a few drops of PDMS except for air bubbles on the surface of the deionized water, and finally place the petri dish in a 60°C oven. After 2 hours, the PDMS film can be peeled off from the water surface, and the PDMS can be added dropwise by adjusting Films of different thicknesses can be obtained. By dropwise adding 37.5 μL of PDMS, a film thickness of approximately 15 μm was prepared.

[0056] γ2. Preparation of conductive layer: After peeling off the PDMS film from the water surface, place it in an oven at 60°C for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com