Method for preparing green tea from summer tea leaves

A technology of green tea and green tea, which is applied in tea treatment before extraction, can solve the problem of mixed hard tea grains, and achieve the effect of reducing sticky matter, lasting fragrance, and clear soup color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 2. Preparation of Aspergillus oryzae and Rhizopus oryzae metabolic enzyme solution

[0031] According to the weight ratio of 86.7% of pure water, 8.3% of expanded soybean soaking juice, and 5.0% of brown sugar, heat and boil for 20 minutes, then cool to 30-40°C, add 0.5-1% of binary bacteria solid culture medium and mix, Sealed fermentation with natural pH at room temperature for 3-5 days, the bacterial liquid can produce a slight sweet distiller's grains smell, filter the beneficial bacterial culture liquid with fine gauze or sand net for 2-3 times, and store it cold in a fresh-keeping cabinet at 3-5°C until use , the active period lasts for half a year.

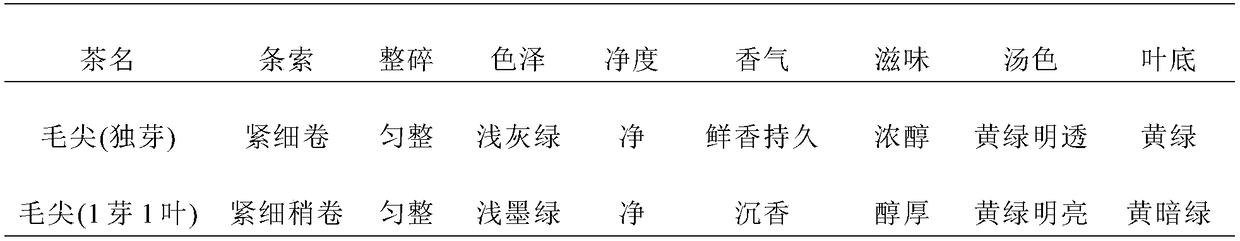

Embodiment 1

[0033] (1) Select the picked summer tea greens: pick the summer single buds that germinated in the same year, and the fresh tea greens should be protected from the hot sun, so that they are not picked on rainy days and the next day after rain; the length of the single buds during selection should not exceed 2.5cm, select the leaves and purple buds and leaves that have been damaged by diseases and insect pests.

[0034] (2) Withering adjustment: place the selected green tea green on the green bed, spread it thinly by 1.5-2.5cm thickness, and spread 4- After 8 hours, the buds and leaves are in a state of dehydration and wilting visually, and the water content of fresh green tea is 55-60%.

[0035] (3) Finishing: Choose an electric drum fixing machine with a diameter of 400mm and a length of 2000mm. Control the temperature at the inlet of the drum to 280°C, the temperature in the middle area to 180°C, and the temperature near the outlet to 120°C. The amount of leaves thrown is sm...

Embodiment 2

[0044] (1) Selecting the picked summer tea greens: pick the middle and small leaf summer tea greens with one bud and one leaf that have just unfolded in the same year. When selecting green leaves, the length of one bud and one leaf should not exceed 3cm, and the leaves and purple buds and leaves that have been damaged by diseases and insect pests should be selected.

[0045] (2) Withering adjustment: place the selected green tea green on the green bed, spread it thinly by 1.5-2.5cm thickness, and spread 4- 8h, the buds and leaves are dehydrated and shriveled visually, and the water content of fresh leaves is 55-60%.

[0046] (3) Finishing: Choose an electric drum fixing machine with a diameter of 400mm and a length of 2000mm. Control the temperature at the inlet of the drum to 280°C, the temperature in the middle area to 180°C, and the temperature near the outlet to 120°C. The amount of leaves thrown is small and uniform. , The feeding and discharging time is controlled withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com