Apparatus and method for producing flour and/or semolina

A flour and coarse-grain technology, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids with airflow, can solve the problems of high energy, high cost of mills, and high energy consumption, and achieve high reliability. Reproducible properties, reduced structural dimensions, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

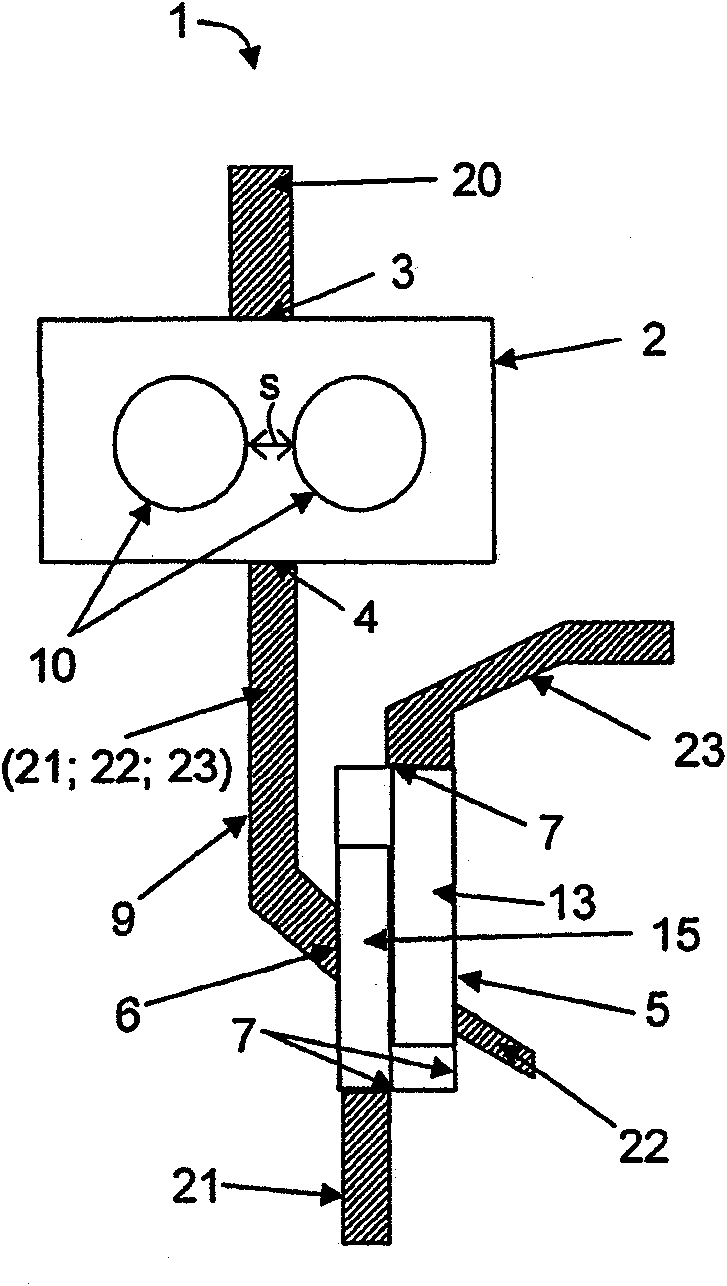

[0100] figure 1 A schematic diagram of a milling arrangement 1 according to the invention is shown.

[0101] The milling arrangement has a material bed roller mill 16 as milling device, as it is in Figure 9 as shown in . The bed roller mill 16 has an inlet 3 and an outlet 4 for grain. The grinding arrangement 1 also has a separating device 5, which has, for example, a press Figure 10 The shown zigzag splitter 13 and a for example according to Figure 12 The planar splitter 15 is shown. The ground grain 20 , comprising coarser milled product 21 , finer milled product 22 and bran 23 , is transported from a bed roller mill 16 to the separation stage 5 by means of a transport device 9 . The diameter of the rollers of the material bed roller mill 9 shown here is 250 mm here. The transport device 9 is designed as a straight pipe so that the milled grain 20 is transported by gravity to the separation stage 5 . Separation stage 5 has an inlet 6 for receiving coarser milled pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com