Rare earth modified surface treating agent for copper and copper alloys and preparation method thereof

A surface treatment agent and rare earth modification technology, which is applied in the coating process of metal materials, can solve the problems of long processing time, environmental hazards, and complicated processing technology, and achieve reduced passivation time, good corrosion resistance, and excellent processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

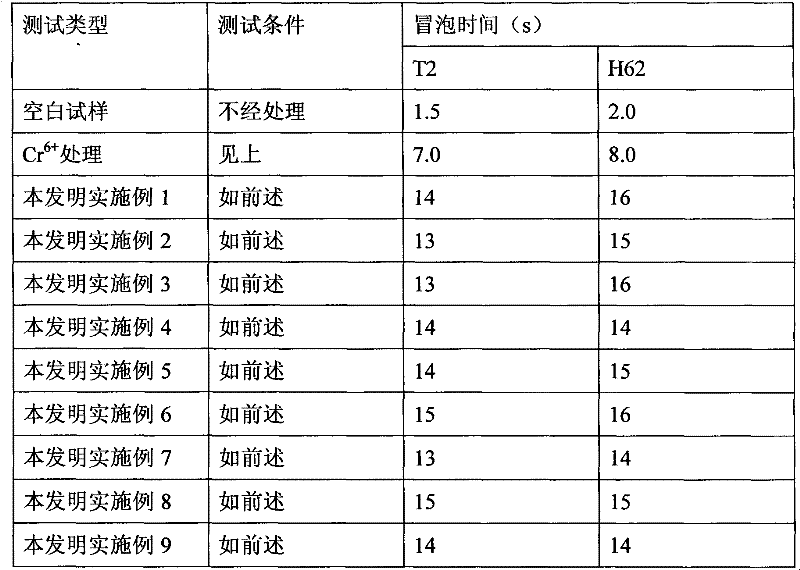

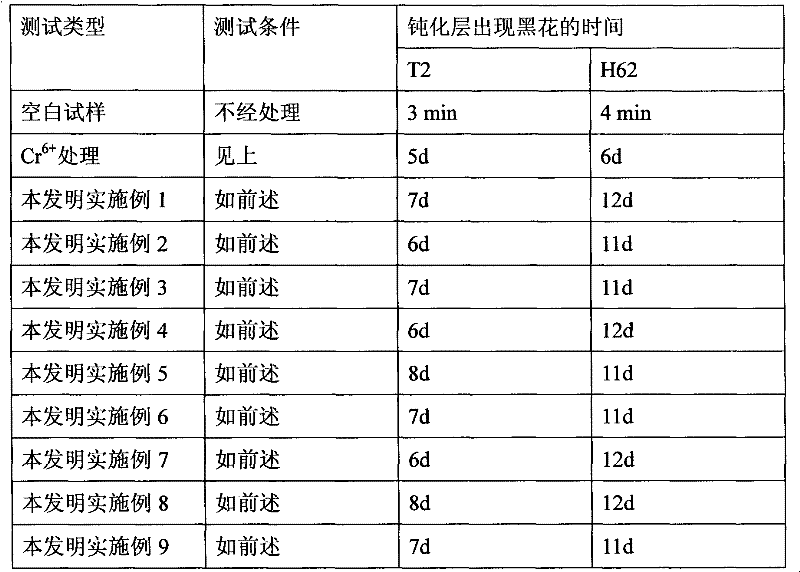

Examples

Embodiment 1

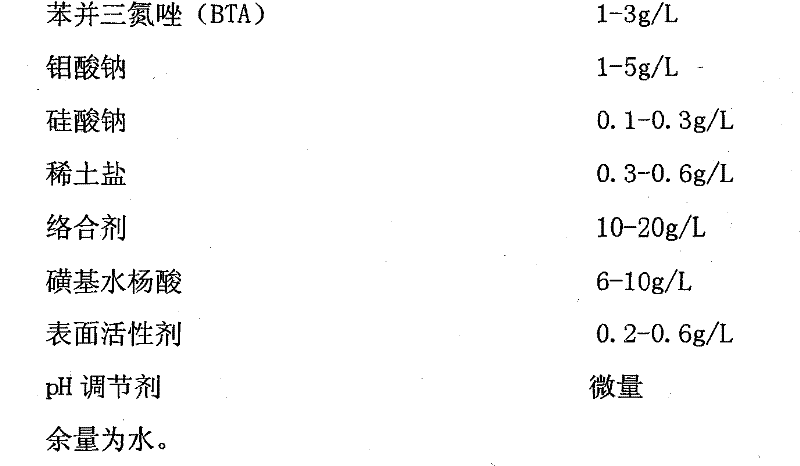

[0031] (1) Take 3g BTA by weighing, add in 200ml water, stir fully and make the semi-finished product treatment liquid after it dissolves for subsequent use;

[0032] (2) take by weighing 1g sodium molybdate respectively, 0.2g sodium silicate, 0.4g lanthanum nitrate and 0.2g cerium nitrate, add respectively in 200ml water, after it dissolves, mix with the semi-finished product treatment liquid that step (1) makes, Fully stir until it is completely dissolved to prepare a semi-finished product treatment solution for use;

[0033] (3) gradually add 15g citric acid, 6g sulfosalicylic acid, 0.4g sodium lauryl sulfate in the semi-finished product treatment liquid that makes in step (2), stir evenly during adding, the component that is to be added earlier After dissolving, continue to add the next component;

[0034] (4) adding an appropriate amount of water to the volume of the treatment agent in the semi-finished treatment liquid prepared in step (3) is 1L, and the pH value is adj...

Embodiment 2

[0036] (1) Take 1g of BTA by weighing, add in 200ml of water, fully stir until it dissolves to prepare a semi-finished product treatment liquid for subsequent use;

[0037] (2) Take by weighing 3g sodium molybdate, 0.1g sodium silicate, and 0.6g lanthanum nitrate, add respectively in 200ml water, after it dissolves, mix with the semi-finished product treatment solution that step (1) makes, fully stir until it is completely After dissolving, the semi-finished product treatment liquid is prepared for use;

[0038] (3) gradually add 10g of citric acid, 8g of sulfosalicylic acid, and 0.2g of sodium lauryl sulfate to the semi-finished product treatment solution prepared in step (2), and stir evenly during the addition process. After dissolving, continue to add the next component;

[0039] (4) adding an appropriate amount of water to the volume of the treatment agent in the semi-finished treatment liquid prepared in step (3) is 1L, and the pH value is adjusted to 3.5-5 with 98% sul...

Embodiment 3

[0041] (1) Take 2g of BTA by weighing, add in 200ml of water, fully stir until it dissolves to prepare a semi-finished product treatment liquid for subsequent use;

[0042] (2) Take by weighing 4g sodium molybdate, 0.3g sodium silicate, 0.3g lanthanum nitrate respectively, add respectively in 200ml water, after it dissolves, mix with the semi-finished product treatment solution that step (1) makes, fully stir until it is completely After dissolving, the semi-finished product treatment liquid is prepared for use;

[0043] (3) Gradually add 18g citric acid, 10g sulfosalicylic acid, and 0.6g sodium lauryl sulfate to the semi-finished product treatment solution prepared in step (2), stir evenly during the addition process, and the components to be added earlier After dissolving, continue to add the next component;

[0044] (4) adding an appropriate amount of water to the volume of the treatment agent in the semi-finished treatment liquid prepared in step (3) is 1L, and the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com