Porous material matrix and composite phase-change heat storage material and preparation methods thereof

A technology of porous materials and heat storage materials, applied in chemical instruments and methods, materials for heat exchange, ceramic products, etc., can solve the problems of low content of inorganic salt phase change materials, low porosity of ceramic matrix, rare and expensive metal matrix, etc. , to achieve good high temperature chemical stability, high infiltration rate, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

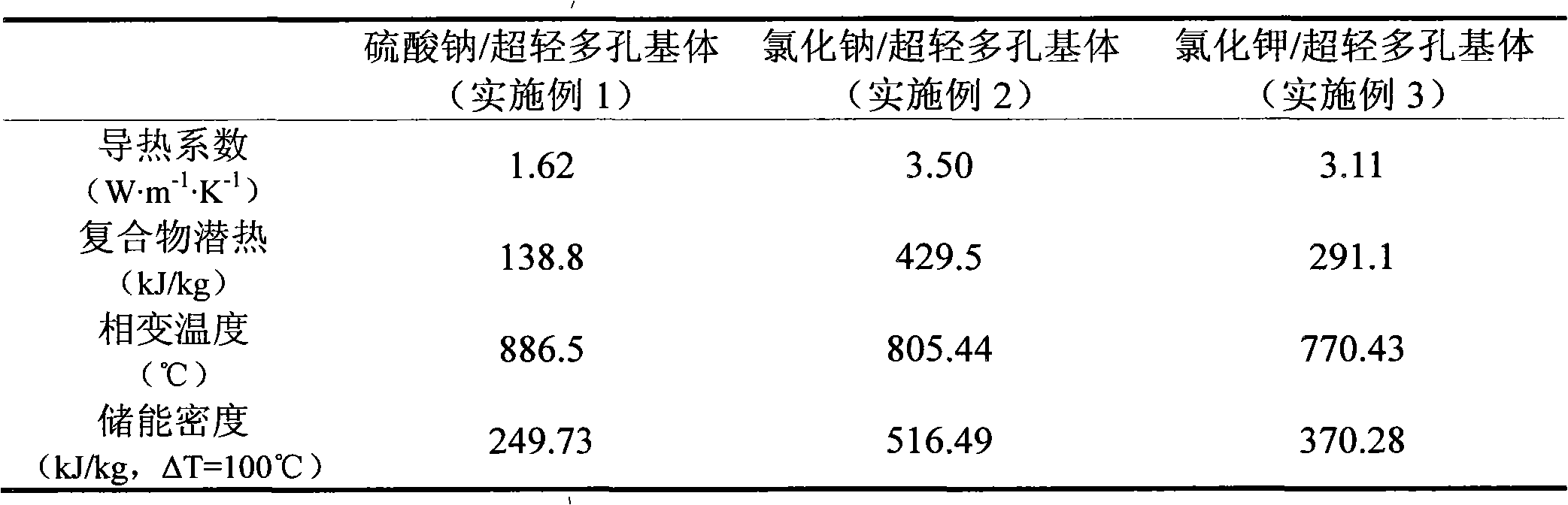

Embodiment 1

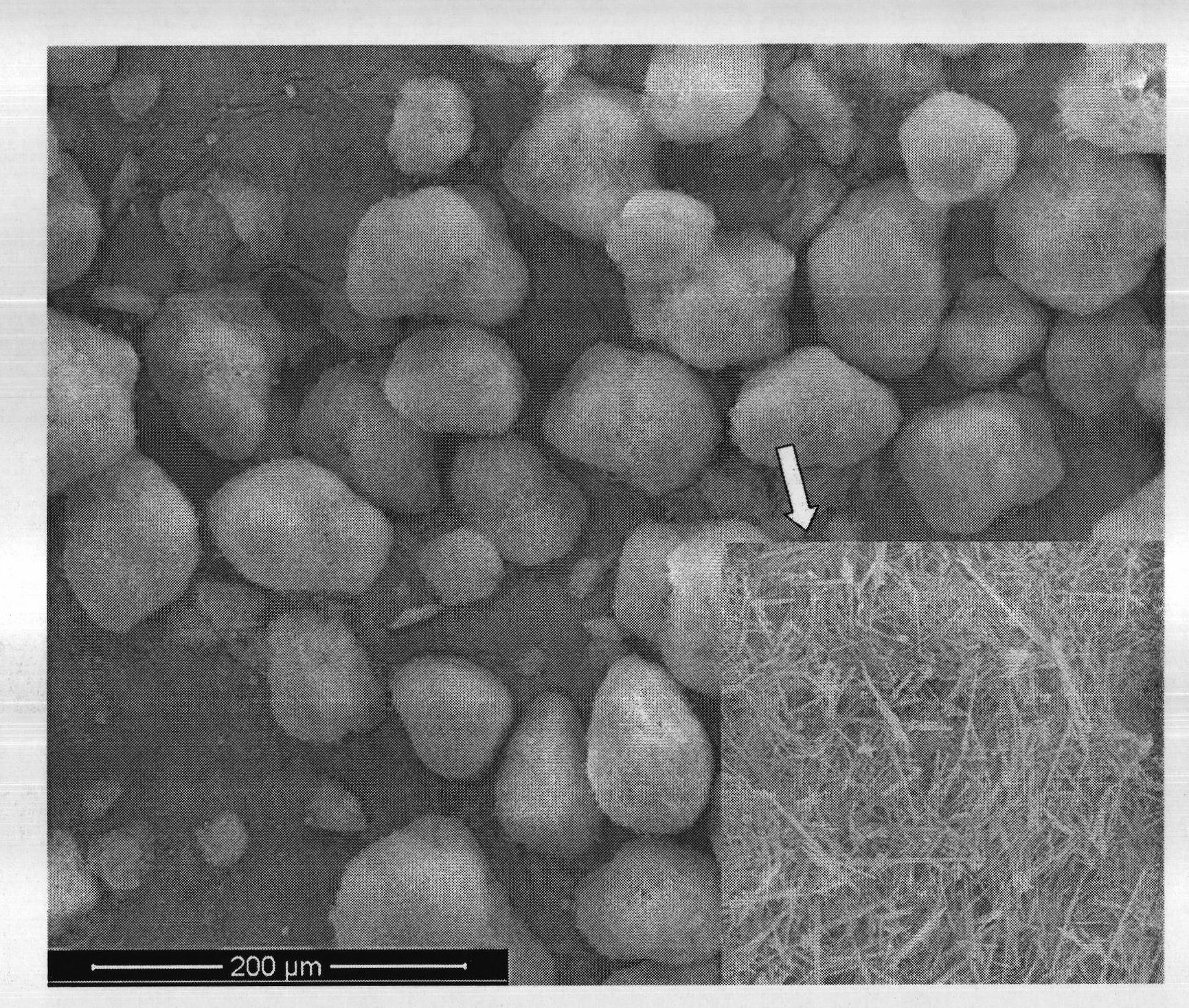

[0035] (1) Preparation of ultra-light porous material matrix

[0036] Put 75g of calcium carbide slag into a ceramic crucible, calcinate at 800°C for 2 hours, cool to room temperature in a desiccator, grind, pass through a 200-mesh sieve, add the obtained carbide slag powder to 85°C deionized water for digestion, and electric Stir with a powerful mixer at 250r / min for 30min, seal and age for 3 days to obtain digested milk of lime. The molar ratio of calcium to silicon is 1:1, and the water-solid ratio (the mass ratio of water to solid phase) is 1:30. Add silicon powder and water to the digested milk of lime, mix well and pour into the reaction kettle. Simultaneously start the stirring motor, heat up to 220° C., hold at 220° C. for 8 hours, then turn off the power, and cool naturally to obtain ultra-light porous material slurry.

[0037] (2) Matrix forming

[0038] The molding method of the base material adopts the suction filtration method: firstly, the ultra-light porous ma...

Embodiment 2

[0043] (1) Preparation of ultra-light porous material matrix

[0044]Add 25g of CaO powder to 60°C deionized water for digestion, stir with an electric powerful mixer at 250r / min for 30min, seal and age for 3d to obtain digested milk of lime. According to the molar ratio Ca:Si=1:0.4, the water-solid ratio (the mass ratio of water to the solid phase) is 1:20, add silica gel and water to the milk of lime obtained after digestion and mix evenly, then pour it into the reaction kettle, Simultaneously start the stirring motor, heat up to 250° C., keep the temperature at 250° C. for 10 hours, then turn off the power, and cool naturally to obtain ultra-light porous material slurry.

[0045] (2) Matrix forming

[0046] The molding method of the base material adopts the suction filtration method: first, mix the ultra-light porous material slurry with 5% (mass fraction) of nano-copper powder evenly, and at the same time slowly pour it into the molding mold. Under the mold is a 200-mesh ...

Embodiment 3

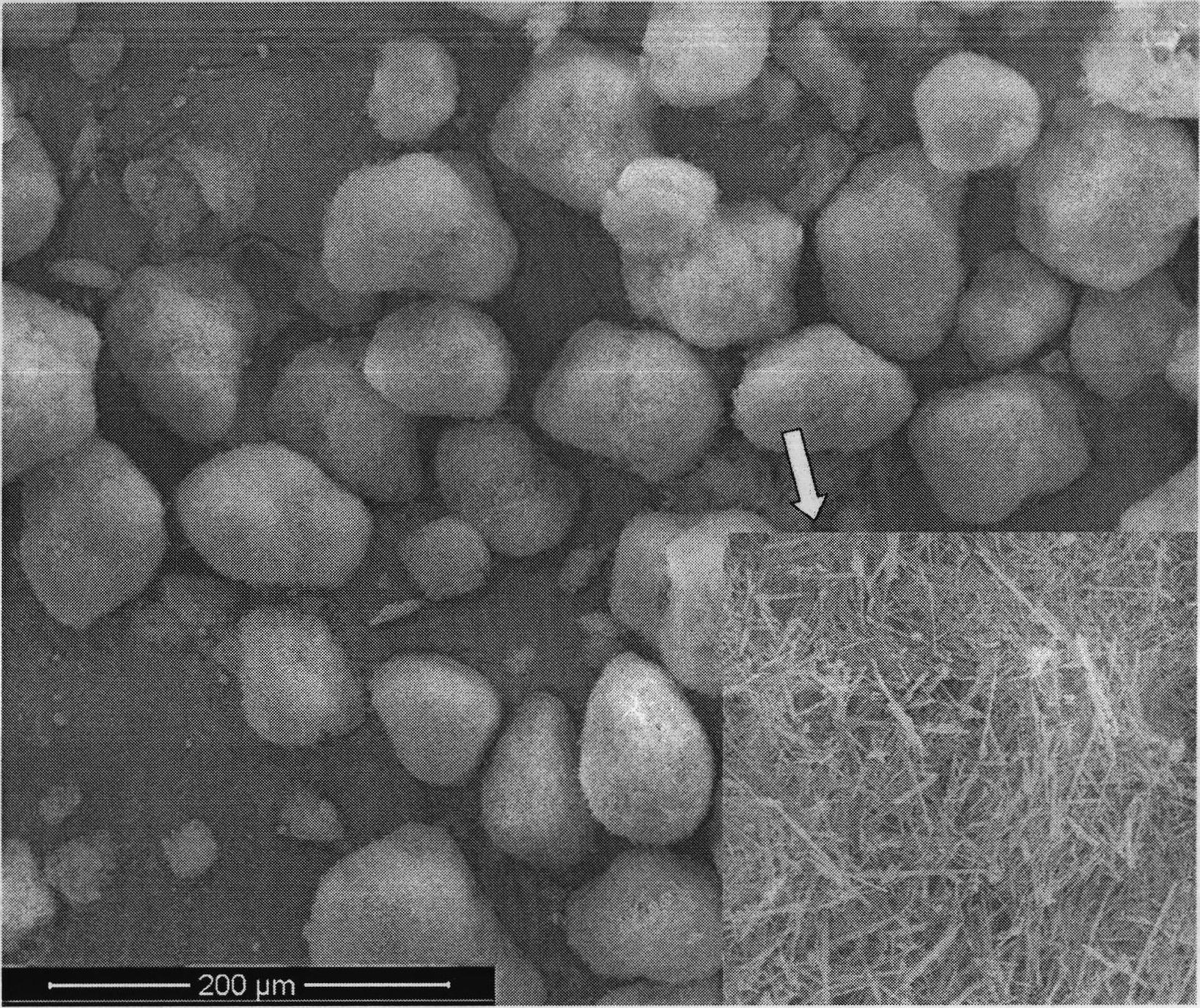

[0051] (1) Preparation of ultra-light porous material matrix

[0052] 25g of Ca(OH) 2 According to the molar ratio Ca: Si = 1: 0.6, the water-solid ratio (the mass ratio of water to solid phase) is 1: 40, mix it with silicon dioxide and water evenly, pour it into the reaction kettle, and start the stirring motor at the same time 250r / Stir for 10 min, heat up to 250°C, hold at 250°C for 6 hours, then turn off the power, and cool naturally to obtain an ultra-light porous material slurry.

[0053] (2) Matrix forming

[0054] The molding method of the base material adopts the natural molding method: first, the ultra-light porous material slurry is mixed with 2% (mass fraction) nano-copper powder and 2% (mass fraction) nano-iron powder, and slowly poured into the molding mold at the same time, the mold The bottom is a 200-mesh stainless steel mesh screen. After it is naturally dried and formed, it is demoulded. Take out the formed matrix material in the mold and put it in a dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com