Processing method for ultraprecise turning of die steel material by adopting diamond cutter

A technology of a diamond tool and a processing method, which is applied in the field of microstructure optical mold production, can solve problems such as cutting failure and diamond tool wear, and achieve the effects of improving wear resistance, prolonging service life, and increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

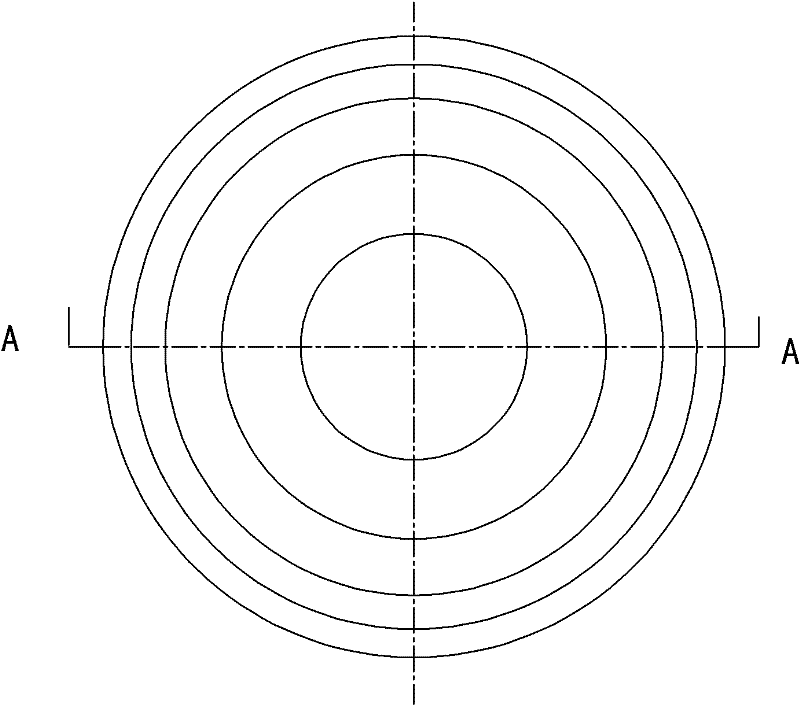

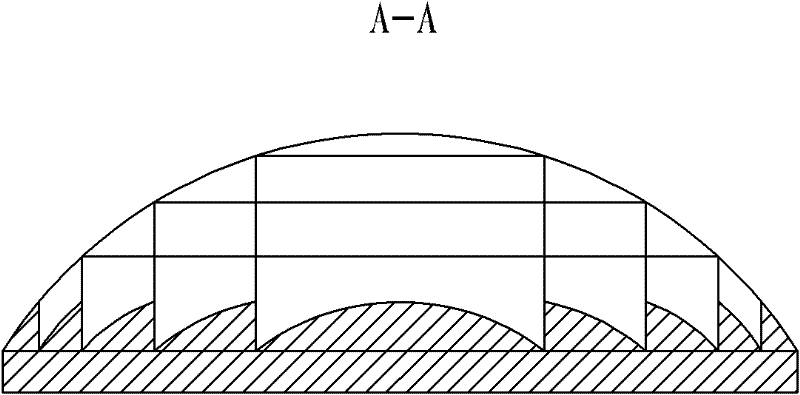

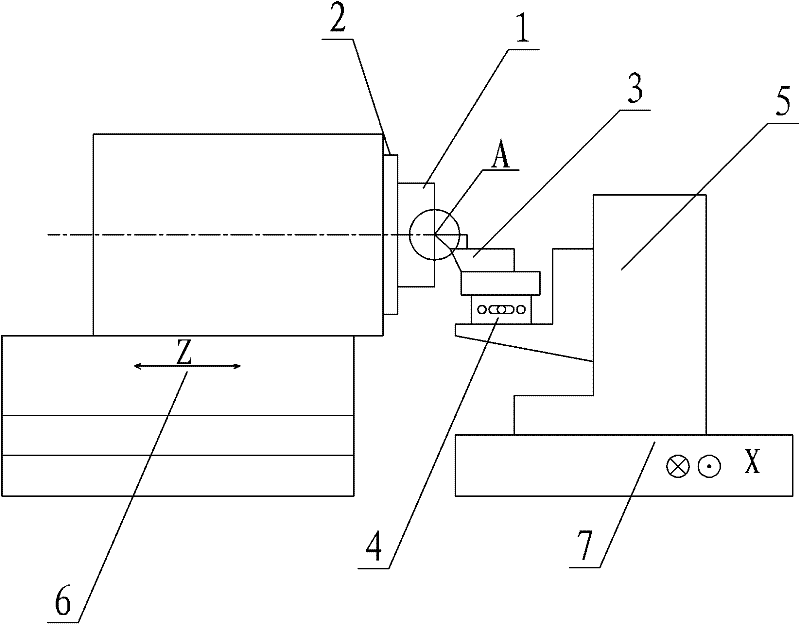

[0012] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the process of the processing method of ultra-precision turning die steel material of this embodiment is as follows:

[0013] Step 1: Carry out conventional quenching and tempering treatment on the workpiece of the mold steel material, so that the hardness of the workpiece of the mold steel material reaches 26HRC-32HRC, and then pretreat the surface of the workpiece of the mold steel material, and the surface of the workpiece of the mold steel material after pretreatment Roughness Ra is less than 1μm, parallelism is less than 2μm;

[0014] Step 2: Perform plasma nitriding treatment on the workpiece surface of the mold steel material, add rare earth infiltrating agent, the volume percentage of nitrogen, hydrogen, and rare earth infiltrating agent is 20%: 60%: 20%, and the nitriding temperature is 540-580°C , the holding time is 4-8 hours, the furnace pressure is 650Pa, and the voltage...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, in step 1 of this embodiment, the hardness of the workpiece of the mold steel material after quenching and tempering treatment reaches 28HRC-30HRC. The workpiece of such hardness die steel material facilitates the pretreatment of the workpiece surface of die steel material. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and figure 2 This embodiment will be described. In this embodiment, the nitriding temperature during the plasma nitriding treatment is 560° C., and the holding time is 5-6 hours. Such nitriding temperature and holding time make the thickness of the nitriding layer 60 μm-80 μm. At this time, the iron atoms and nitrogen atoms in the nitriding layer can achieve the most sufficient combination, reducing the chemical reaction between the iron atoms and the carbon atoms in the diamond. The probability and the probability of the carbon atoms in the diamond diffusing to the workpiece material, thereby achieving the purpose of inhibiting the rapid wear of the tool. Other method steps are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com