Miniature high-voltage capacitor and making method thereof

A high-voltage capacitor and miniature technology, which is applied in the direction of capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve the problems of internal electrode compactness and continuity, etc., achieve good market application prospects, weaken electrode edge effects, and ensure compactness and The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

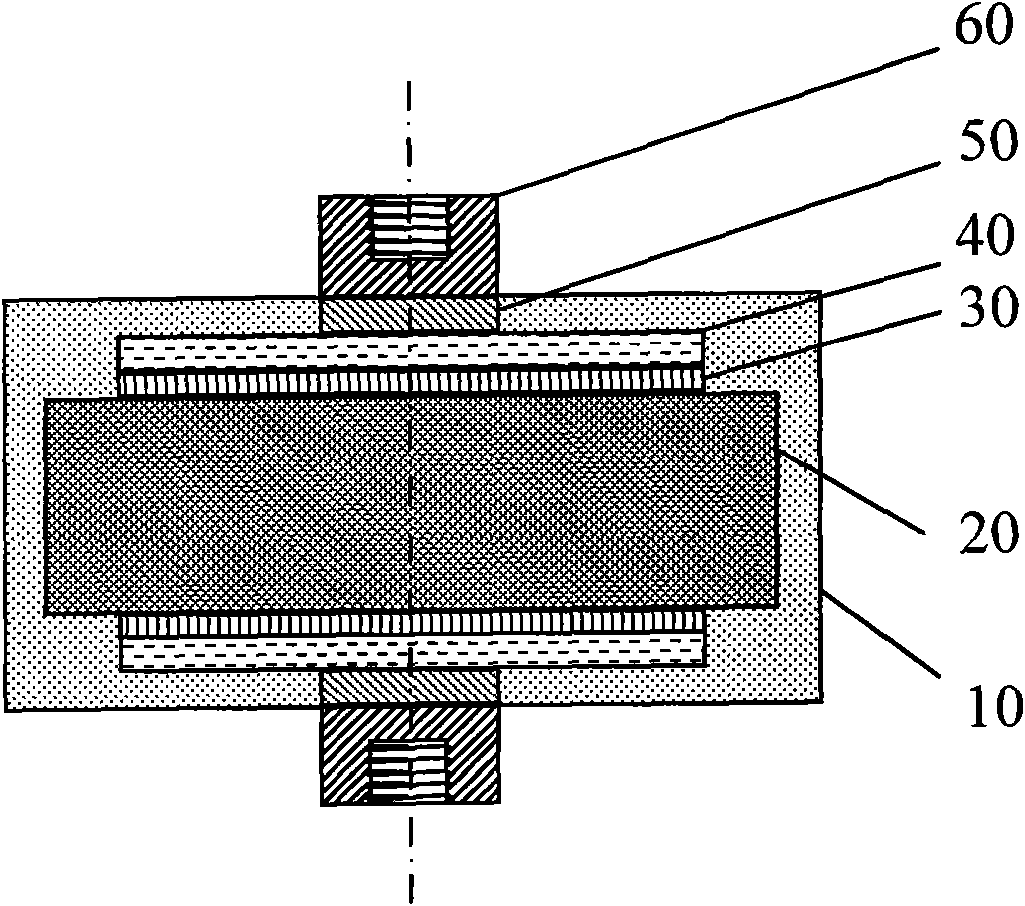

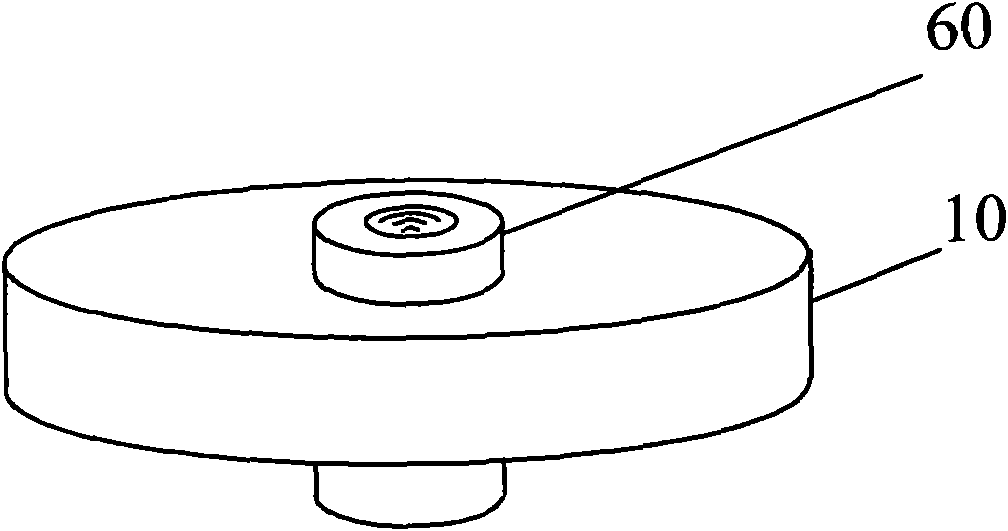

[0046] figure 1 It is a schematic cross-sectional view of a miniature high-voltage capacitor in the present invention, figure 2 It is a three-dimensional schematic diagram of a miniature high-voltage capacitor in the present invention, wherein 10 is an AB type epoxy resin material, 20 is a glass ceramic disc, 30 is an inner electrode of a gold film, 40 is a silver paste transition electrode, and 50 is an In-Sn50 alloy sheet, 60 is the outer electrode terminal of the red copper sheet.

[0047] Analytical pure Na 2 CO 3 , PbO, Nb 2 o 5 , SiO 2 The raw material powder is mixed evenly according to the ratio of 2:2:3:6 and melted at 1400°C for 2 hours. The melt is cast into a block glass body with a size of about 25mm×25mm×3mm in a preheated steel mold, and the stress is relieved. After annealing for 3 hours, a colored transparent glass body was obtained. The glass body is nucleated and crystallized at different temperatures, that is, nucleated and crystallized at 700°C, 75...

Embodiment 2

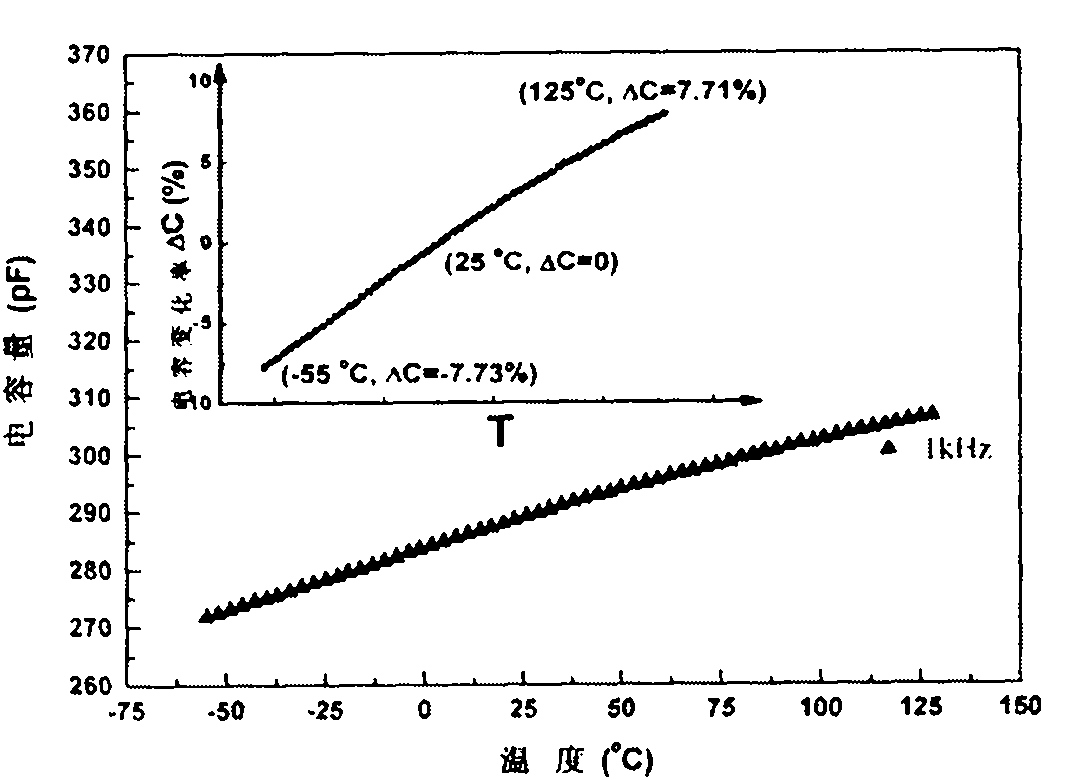

[0049] Analytical pure Na 2 CO 3 , PbO, Nb 2 o 5 , SiO 2 The raw material powder is mixed evenly according to the ratio of 1:1:2:3, and then melted at 1400°C for 2 hours. The melt is cast into a block glass body with a size of about 25mm×25mm×3mm in a preheated steel mold, and the stress is relieved. After annealing for 3 hours, a colored transparent glass body was obtained. The glass body was nucleated and crystallized at different temperatures (700°C, 750°C, 800°C, 850°C, 900°C) for 3 hours to obtain glass ceramics, and then trimmed, sliced, spheronized, ground and polished to obtain a diameter of Φ20± The thickness of 0.01mm is 0.50±0.01mm, and the surface is polished (smoothness is higher than Ra0.1). After testing, the dielectric constant of glass ceramics obtained at different crystallization temperatures varies with the test frequency. Figure 4 shown. Select a piece of glass ceramic disc 20 with a dielectric constant of about 350 and a crystallization temperature...

Embodiment 3

[0051] Analytical pure Na 2 CO 3 , PbO, Nb 2 o 5 , SiO 2 The raw material powder is mixed evenly according to the ratio of 2:2:3:6 and melted at 1400°C for 2 hours. The melt is cast into a block glass body with a size of about 25mm×25mm×3mm in a preheated steel mold, and the stress is relieved. After annealing for 3 hours, a colored transparent glass body was obtained. The glass body is nucleated and crystallized at different temperatures (700°C, 750°C, 800°C, 850°C, 900°C) for 3 hours to obtain glass ceramics, and then trimmed, sliced, rounded, ground and polished to obtain a diameter of Φ5±0.01mm in thickness 0.50±0.01mm, the surface is polished (smoothness is higher than Ra0.1) discs, after testing, the dielectric constant of glass ceramics obtained at different crystallization temperatures varies with the test frequency distribution as follows Figure 4 shown. Select a piece of glass ceramic disc 20 with a dielectric constant of about 170 and a crystallization temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com